Components for the hydrogen drive in the mass market

- Details

- Hits: 6889

Schaeffler strengthens its commitment around the Hydrogen power: The automotive and industrial supplier joined the global hydrogen interest group Hydrogen Council based in Belgium in 2020 as a steering member. The Hydrogen Initiative consists of 81 leading companies from the fields of energy, transport and industry. The aim of the members is to advance hydrogen technology in the direction of industrialization.

Establish a hydrogen car globally

“We want one CO2-neutral, sustainable mobility design taking into account the entire energy chain. In doing so, we are relying on the enormous future potential of green hydrogen along the entire value chain, ”says Klaus Rosenfeld, Chairman of the Board of Management of Schaeffler AG. "Joining the Hydrogen Council enables us to further advance hydrogen cars and fuel cell technology together with strong partners and to establish it worldwide."

Interview: Digital service for rolling bearings

Interview: Digital service for rolling bearings

Maximum sustainability and CO2 neutrality are the goal when it comes to mobility and the associated energy chain. "Hydrogen technology offers huge potential for emission-free drive solutions and energy storage," says Klaus Rosenfeld. "With our core competencies in material, forming and surface technology, efficient large-scale production of key components for the future hydrogen economy should make a significant contribution to our corporate success."

The further establishment and expansion of research and development partnerships for the further development of components for fuel cells is an important strategic concern. To the Hydrogen Bündnis Bayern joined Schaeffler last year.

Key components for the fuel cell

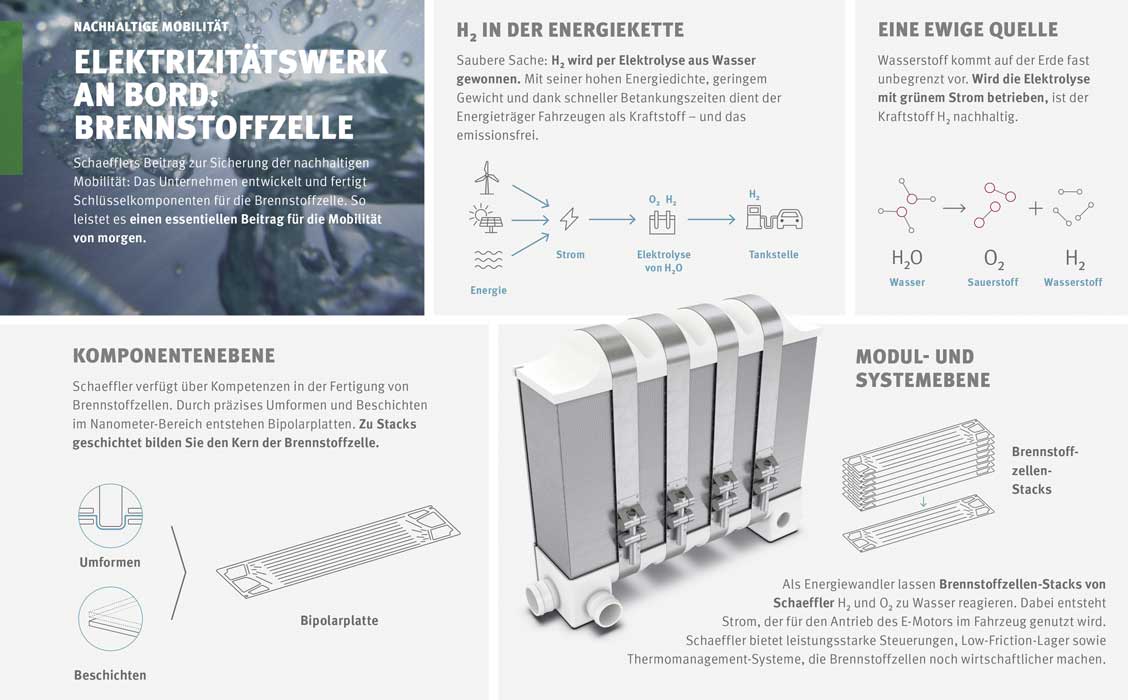

The automotive supplier has been focusing on the value chain of key components for the fuel cell for a long time. Through precise forming and coating in Thin film area bipolar plates are produced, which are stacked in stacks and are an important part of the fuel cell.

Seven good reasons for hydrogen propulsion and fuel cells

Seven good reasons for hydrogen propulsion and fuel cells

The fuel cell stacks are energy converters that allow H₂ and O₂ to react to form water. This generates the electricity required to drive the electric motor of the fuel cell car. Additional competencies such as special high-performance bearings, electronic controls, smart thermal management modules or components for passive hydrogen recirculation expand Schaeffler's portfolio for optimized fuel cells.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

Planetary gear + strain wave gear precision from Schaeffler

spindle bearing | The Vacrodur high-performance elements

linear guide | Precise, light, durable