Smart maintenance: what influence does Industry 4.0 have?

- Details

- Hits: 9347

After the successful "Study Maintenance 4.0 - Global Survey" for the development of Smart maintenance in the DACH region is researching this FIR at RWTH Aachen Now questions about the status quo of technologies and value creation potentials of Maintenance 4.0 in an international context. The Maintenance Competence Center cooperates with this BCG (Boston Consulting Group).

Other partners are the EFNMS (European Federation of National Maintenance Societies) and the ASQ (American Society for Quality). In a global study, the partners are investigating the impact of Industry 4.0 on maintenance and service. How do companies receive important impulses for future competitive design as part of smart maintenance.

Smart maintenance in the age of globalization

Efficient maintenance of machines and systems gains in the course of increasing Globalisation are growing in importance. Smart Maintenance combines digital, intelligent technologies using the tried and tested methods of classic maintenance. In this way, considerable increases in performance and efficiency can be implemented.

Predictive maintenance with artificial intelligence for robots

Predictive maintenance with artificial intelligence for robots

Maintenance 4.0 opens up with new technologies and business models enormous potential. Maintenance personnel can thus better meet the requirements of globally networked markets and thus ensure high product availability in the event of strongly fluctuating demand and short product life cycles. The risk of failure of machines and systems with an increasing number of variants can also be minimized.

Study with best practices statements

In addition to determining the location, the results of the survey are intended to identify promising applications and the effects of corresponding maintenance measures on the most important ones KPIs in the company detect. Best practice statements should also be used to derive the skills and competencies required in maintenance in the future.

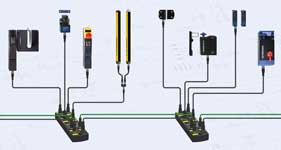

Safe field box with reduced wiring effort

Safe field box with reduced wiring effort

General technical knowledge

What is Smart Maintenance?

Smart maintenance means maintenance based on digitization. This includes maintenance, servicing and servicing of machines and systems with the aim of reducing the total cost of ownership (TCO) or overall costs. Cyber-physical systems, Artificial intelligence (AI) and the Internet of Things (IoT). are sub-areas Predictive Maintenance or predictive maintenance and Preventive Maintenance or preventive maintenance. Smart maintenance is a building block for Industry 4.0