Sensor for safe autonomous driving in all weathers

- Details

- Hits: 5179

Mitsubishi Electrics Information Technology R&D Center in Japan has a new one sensor technology developed, which enables a highly precise recording of vehicle parameters even in thick fog or heavy rain. The technology is said to be a robust function of autonomous and assisted driving systems even in harsh weather conditions, under which the detection accuracy of conventional sensors decreases.

Mitsubishi Electrics Information Technology R&D Center in Japan has a new one sensor technology developed, which enables a highly precise recording of vehicle parameters even in thick fog or heavy rain. The technology is said to be a robust function of autonomous and assisted driving systems even in harsh weather conditions, under which the detection accuracy of conventional sensors decreases.

The general research and development into sensors used in autonomous and assisted driving systems continues to focus on improving recognition accuracy. These systems rely on various types of sensors that confirm positions, speeds, magnitudes, etc. of obstacles in the way of vehicles. However, conventional systems with such sensors have not provided reliable performance in, for example, dense fog or heavy rain, since these conditions degrade the transmission of electric and laser waves, as well as the camera vision.

stepper motor | Precise low cost positioning

stepper motor | Precise low cost positioning

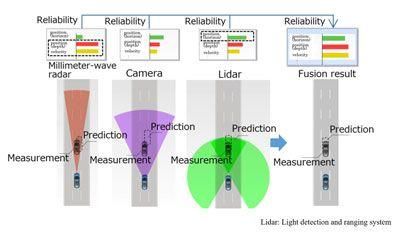

The newly developed robust technology selects and combines data from several sensors on the vehicle based on their reliability. Time-series data collected by different sensors (speed, width, orientation, distance, etc.) are analyzed in real-time to predict how reliable the data of each sensor will be based on the weather conditions. By selecting and combining data with high reliability, high-accuracy detection is possible even in harsh weather conditions.

Safe emergency braking in the test center

The technology was used in a test center in Japan in a vehicle with autonomous full braking system (AEB) to verify the performance of real vehicles in inclement weather. It was confirmed that the AEB system was able to perform safe emergency braking even under conditions in which conventional sensors would otherwise lose a lot of accuracy.

The technology was used in a test center in Japan in a vehicle with autonomous full braking system (AEB) to verify the performance of real vehicles in inclement weather. It was confirmed that the AEB system was able to perform safe emergency braking even under conditions in which conventional sensors would otherwise lose a lot of accuracy.

In the future, the company will continue to test the technology in actual environments and continue the development with the goal of marketing from 2023. It is expected that the technology can be used in autonomous vehicles in the future to ensure safe and accurate lane changes even in harsh weather conditions.

Selection and combination of data from different sensors

Different sensors collected time series data such as speed, width, orientation, and distance, which were compared to the predicted data and values based on the corresponding functions. Real-time calculations predicted the reliability of individual sensor data, which depends on the weather. The system then chose to forecast data as very reliable and combined it. Thus, the function of autonomous and assisted driving systems could be demonstrated even in dense fog or heavy rain.

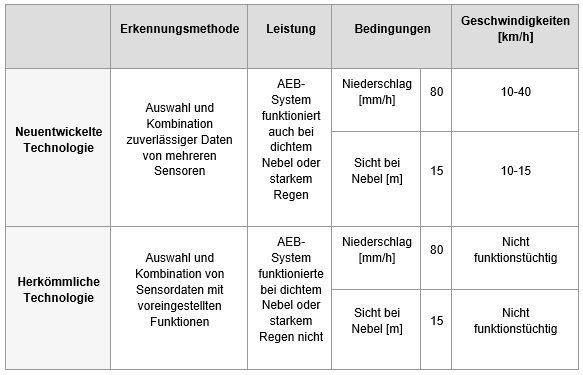

AEB system also powerful in inclement weather

The tests, which simulate harsh weather conditions, were conducted at a facility owned by the non-profit Japan Automobile Research Institute. An AEB system was tested in heavy rain (precipitation of 80 mm / h) with a maximum vehicle speed of 40 km / h. Thanks to the successful detection of objects that triggered the emergency braking, a normal function of the AEB system could be verified. In addition, the system was tested in thick fog with a visibility of 15 m and a vehicle speed of 10 to 15 km / h. All heavy rain tests were repeated at night. In addition, tests were carried out in which the recognition accuracy of the camera was significantly impaired by background lighting at a vehicle speed of 10 to 40 km / h. The AEB system was successfully activated under all conditions.

The tests, which simulate harsh weather conditions, were conducted at a facility owned by the non-profit Japan Automobile Research Institute. An AEB system was tested in heavy rain (precipitation of 80 mm / h) with a maximum vehicle speed of 40 km / h. Thanks to the successful detection of objects that triggered the emergency braking, a normal function of the AEB system could be verified. In addition, the system was tested in thick fog with a visibility of 15 m and a vehicle speed of 10 to 15 km / h. All heavy rain tests were repeated at night. In addition, tests were carried out in which the recognition accuracy of the camera was significantly impaired by background lighting at a vehicle speed of 10 to 40 km / h. The AEB system was successfully activated under all conditions.

Forecasting features for environment detection

A pair of Lidar sensors does not perform well in fog (airborne water absorbs pulsed laser signals). Therefore, based on data from a lidar, the system can determine fog present under such conditions. The results of this test are taken into account when calculating the reliability to enable more accurate detection functions.

You might also be interested in...

Artificial Intelligence | trends and developments

Predictive maintenance for robotics, machines and systems

Mitsubishi Electric | Automating the World

Cobot | Discover collaborative robots as a new employee

Intelligent CNC control for machine tools