for the optimal coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

for the optimal coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Quality products have high quality Surfacesso that they last a long time and are visually appealing. Corrosion protection, wear protection and decorative properties place special demands on the surface. We report in our section Surface Technology about coatings by painting, powder coating as well as PVC coatings, surface finishing, dosing, lasers and others Processthat give the surface robustness and shine, for example, or simply make it feel appealing. Our surface technology is aimed at designers and development engineers who manufacture their components from aluminum, steel, stainless steel and much more. want to provide the best surfaces.

Find out about news on surface technology at Protection and for the optics Of your new products!

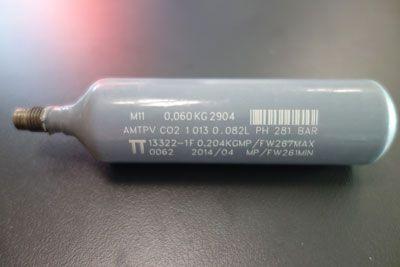

SIC Marking introduces the “i103 HD-Laser” laser marker, with which direct markings can be produced precisely on metal and plastic parts thanks to the short pulse fiber laser used. Its technical properties make it possible for metals and plastics to be labeled with even more contrast and legibility - even with less than optimal surfaces.

SIC Marking introduces the “i103 HD-Laser” laser marker, with which direct markings can be produced precisely on metal and plastic parts thanks to the short pulse fiber laser used. Its technical properties make it possible for metals and plastics to be labeled with even more contrast and legibility - even with less than optimal surfaces.

Ceramic Polymer has launched a new, solvent-free interior tank coating with extremely high protective functions. Thanks to the special physical properties of this new development, stainless steel is reliably protected against severe corrosion damage. The new development is absolutely resistant to a large number of chemicals and gases up to a permanent operating temperature of 150 ° C.

Ceramic Polymer has launched a new, solvent-free interior tank coating with extremely high protective functions. Thanks to the special physical properties of this new development, stainless steel is reliably protected against severe corrosion damage. The new development is absolutely resistant to a large number of chemicals and gases up to a permanent operating temperature of 150 ° C.

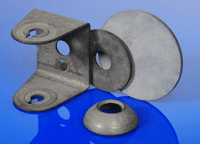

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

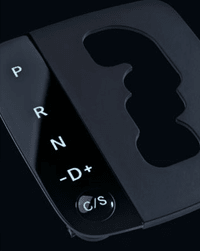

Whether direct and indirect light accents, colored accent strips or mirror surfaces: With an innovative plastic coating, components in and around the vehicle can be designed in a variety of ways. Benseler shows how wide the range of what is feasible with plasma vacuum coatings (PVD) in combination with UV paint is.

Whether direct and indirect light accents, colored accent strips or mirror surfaces: With an innovative plastic coating, components in and around the vehicle can be designed in a variety of ways. Benseler shows how wide the range of what is feasible with plasma vacuum coatings (PVD) in combination with UV paint is.

Datalogic presents its new "Arex 400" laser. Together with the “Marvis” software, the user receives a complete traceability solution. The Arex series is a family of compact fiber lasers for high-speed marking on metal and plastic for the automotive and electronics industries.

Datalogic presents its new "Arex 400" laser. Together with the “Marvis” software, the user receives a complete traceability solution. The Arex series is a family of compact fiber lasers for high-speed marking on metal and plastic for the automotive and electronics industries.

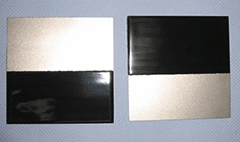

Hydrogen embrittlement is an omnipresent issue when it comes to protecting against corrosion by coating the surface of metals. This applies above all to safety-relevant components that are subject to particularly high strength requirements. Ebbinghaus Verbund uses zinc thermo diffusion (ZTD) for the corrosion protection of bulk material and thus eliminates this problem.

Hydrogen embrittlement is an omnipresent issue when it comes to protecting against corrosion by coating the surface of metals. This applies above all to safety-relevant components that are subject to particularly high strength requirements. Ebbinghaus Verbund uses zinc thermo diffusion (ZTD) for the corrosion protection of bulk material and thus eliminates this problem.

RIO has developed the new surface technology process "Betenio" for metal pretreatment, which offers significant advantages compared to the conventional processes of blasting and acid treatment.

RIO has developed the new surface technology process "Betenio" for metal pretreatment, which offers significant advantages compared to the conventional processes of blasting and acid treatment.

Stainless steel naturally offers little chance of microbial colonization. But that's enough in the Health sector or at vending machines and counters in public spaces. Here effectively protects the antimicrobial coating from Sedlbauer. The special lacquer guarantees optically brilliant surfaces antibacterial, long-term resistant and gives germs no chance to settle.

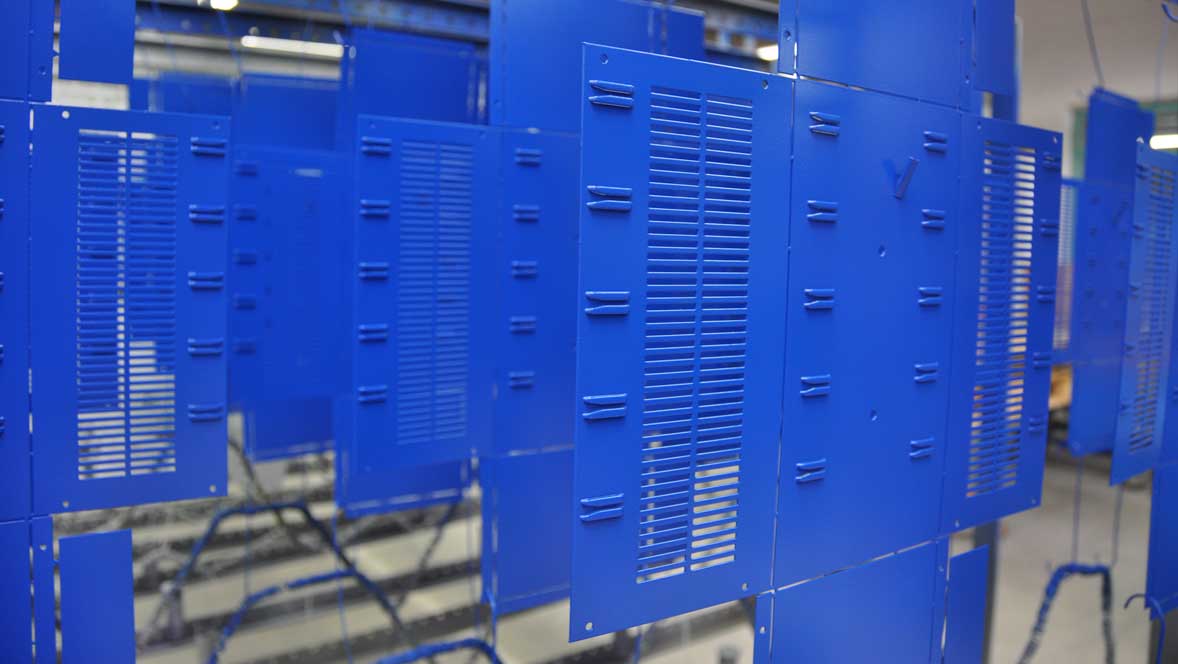

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

Klüber Lubrication presents new water-miscible sliding varnishes without flammable solvents for long-life dry lubrication as well as for special applications with pre-start lubrication. In addition to the well-known advantages of dry lubrication, the new product line offers a significant improvement in sliding and an increased tightness of O-rings due to reduced gas and liquid permeability.

Klüber Lubrication presents new water-miscible sliding varnishes without flammable solvents for long-life dry lubrication as well as for special applications with pre-start lubrication. In addition to the well-known advantages of dry lubrication, the new product line offers a significant improvement in sliding and an increased tightness of O-rings due to reduced gas and liquid permeability.