Carbide grades for demanding cast machining

- Details

- Hits: 15706

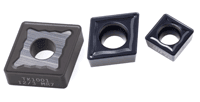

The carbide grades TK1001 and TK2001 from Seco Tools are convincing in demanding casting processes and, thanks to the patented "Duratomic" coating, achieve a long service life. After the introduction of 14 Duratomic grades, the TK1001 and TK2001 are a new generation of cutting materials for turning cast materials on the market.

The carbide grades TK1001 and TK2001 from Seco Tools are convincing in demanding casting processes and, thanks to the patented "Duratomic" coating, achieve a long service life. After the introduction of 14 Duratomic grades, the TK1001 and TK2001 are a new generation of cutting materials for turning cast materials on the market.

TK1001, the MT-CVD/Duratomic coated carbide grade, is primarily suitable for high-speed machining in castings where high wear resistance and abrasion resistance are required. The Duratomic coating technology enables greater wear resistance and longer service life, improves layer adhesion and enables very good resistance to adhesion and avoids sudden layer flaking.

TK2001 is always used when the machining conditions require high toughness and extreme cutting edge stability. TK2001, thanks to the Duratomic coating, is able to achieve very good performance in unstable conditions or in interrupted cutting, especially in terms of notch wear. In addition, TK2001 is the first choice Icing with spheroidal graphite.

Both grades are characterized by a high degree of reliability, especially under the boundary conditions of fluctuating qualities of used batches - both gray and nodular cast iron.