Vacuum gripper for the production of batteries, solar cells and Composites

- Details

- Hits: 10063

J. Schmalz presents the SBG special gripper for automated battery cell production. This means that the user can handle electrodes with precise positioning and without damage. The SBG enables a throughput of more than 60 cycles / min and, in connection with a double-layer sensor, a very high level of process reliability. Other grippers will also be presented.

J. Schmalz presents the SBG special gripper for automated battery cell production. This means that the user can handle electrodes with precise positioning and without damage. The SBG enables a throughput of more than 60 cycles / min and, in connection with a double-layer sensor, a very high level of process reliability. Other grippers will also be presented.

The special gripper SCG was designed for the handling and separation of CF dry areas. The high volume flow and the large contact surface with the precisely defined adjacent suction openings prevent damage to the CF blank. In addition, they enable a fast build-up of the vacuum for dynamic handling cycles.

The SWGm wafer gripper was developed for the photovoltaic industry, which enables process-reliable, slip-free and damage-free handling with cycle times> 1s. The modular design of the SWGm can be adapted to different wafer formats. With additional modules, double layer control, breakage control “on the fly” and position determination are possible, which further increases process reliability.

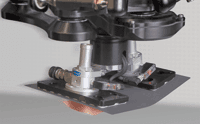

Automated manufacturing processes in the automotive industry master the suction grippers of the SAXM series. They have a large stroke, which optimally adapts to complex contoured sheets. The teat geometry allows for minimal intake times, high inherent stability when sucked in and extreme holding and transverse forces, especially on oiled surfaces. The material Elastodur makes the suction pads extremely resistant to wear, even under the influence of ozone and aggressive drawing oils.

For the packaging industry there is the new system kit for vacuum end effectors (VEE), with which individual grippers can be configured in a very short time for use in case packers, top loaders, carton or tray erectors.