New canned motor pump for chemical and process engineering

- Details

- Hits: 4495

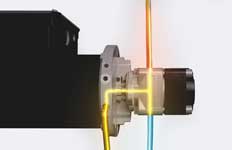

For the first time, KSB is presenting the absolutely leak-free canned motor pumps of the “Ecochem Non-Seal” series. These are designed for the transport of dangerous, aggressive, flammable and explosive liquids. They are also used to convey toxic, very hot or cold, as well as volatile and valuable liquids.

For the first time, KSB is presenting the absolutely leak-free canned motor pumps of the “Ecochem Non-Seal” series. These are designed for the transport of dangerous, aggressive, flammable and explosive liquids. They are also used to convey toxic, very hot or cold, as well as volatile and valuable liquids. The series is a combination of the standardized chemical pump “Mega CPK” and the canned motors from Nikkiso. The pumps have dimensions in accordance with the ISO 2858 standard and meet the requirements of the DIN / EN / ISO 15783 and API 685 standards. The energy-optimized electrical motor design ensures economical operation. The quietly running motor has a corrosion-resistant can made of Hastelloy (2.4610). The series is available in four standard versions: in one version each for standard chemicals, for heat transfer media, for polymerizing or ferrite-containing media and in a special version for low-boiling components and liquefied gases.

The units are designed for explosion protection II 2 G c Ex de IIC according to ATEX, TR and IEC Ex, temperature classes T1 to T5 and for standard media temperatures from -40 ° to +400 ° C. The maximum delivery head is 236 m and the largest flow rate is 690 m3/H. Sliding bearings made of pure silicon carbide or a silicon carbide-graphite compound lubricated by the medium offer the possibility of optimally adapting the bearings to the operation of the pumps and to the medium.

Servo hydraulics instead of hydraulics: calculator and new developments

Servo hydraulics instead of hydraulics: calculator and new developments

In order to prevent blocking by media which become viscous or solid during cooling down, the pump housing can be optionally heated. The engines have a power up to 75 kW. 16 different motor sizes and a modular system for engine mounts are available.