Wave Gear | for industrial robots, cobots + handling

- Details

- Hits: 11860

Strain wave gear are suitable for applications that require precise positioning and high repeatability. the Schaeffler Group puts on the Hannover Messe equal three new precision wave gears before: for Cobots, Industrial robots and torque applications. The kit for fully integrated Tribo strain wave gear from Igus has everything a Cobot needed to accelerate low-cost automation. We present these and other innovations to wave gears to you here:

Contents

- Sensorized strain wave gears with high precision for robotics

- Functional principle and structure of a Datorker harmonic drive

- Plug and play gearboxes for robots

- Exact tension shaft gears for robots

- Angular needle bearing and gear unit for robots and cobot

- Installation kits with the highest torque density for handling systems

- Functional principle and structure of a galaxy strain wave gear

- The strain wave gear principle with Harmonic Drive

- Frequently asked questions

Sensorized strain wave gears with high precision for robotics

20.04.2023/XNUMX/XNUMX | the RT precision harmonic drive from Schaeffler were designed for particularly dynamic and demanding Robotic Applications designed with high torque levels. Wave gears with a fully integrated one are available as an option torque sensors.

20.04.2023/XNUMX/XNUMX | the RT precision harmonic drive from Schaeffler were designed for particularly dynamic and demanding Robotic Applications designed with high torque levels. Wave gears with a fully integrated one are available as an option torque sensors.

Functional principle and structure of a harmonic drive

15.03.2021/XNUMX/XNUMX | The video shows how a Datorker harmonic drive from Hiwin is set up and how it works:

Plug-and-play gearbox construction kit for robots

18.02.2021/XNUMX/XNUMX | They play a particularly important role Transmission as the heart from modern Robotn. Igus Last year, introduced a new generation of Tribo wave gears for movement on the 5th robot axis. Friction and wear are optimized by lubricating tribo polymers.

18.02.2021/XNUMX/XNUMX | They play a particularly important role Transmission as the heart from modern Robotn. Igus Last year, introduced a new generation of Tribo wave gears for movement on the 5th robot axis. Friction and wear are optimized by lubricating tribo polymers.

Exact tension shaft gears for robots

03.07.2020 | Robot must be precise, efficient and torsionally stiff. Also in machine tools, Automation and semiconductor manufacturing, precision is increasingly required. Nidec Graessner offers the stress wave drive Flexwave (picture above) for these applications. The lightweight gear also offers a low starting torque, high gear ratios and zero backlash.

Scara robots for digital transformation

Scara robots for digital transformation

The voltage wave gearboxes from Nidec are available in sizes 35 – 80. They allow translations up to i = 120: 1. With 100 g to 3,4 kg, the Flexwave gearboxes are suitable for the Lightweight. They deliver a very high maximum torque of up to 346 Nm on the output side. They can be installed quickly and safely with various installation kits.

If the eccentric is in use, Flexwave and elastic bearings take one elliptical shape at. Flexwave and ring gear stably mesh at both ends of the long axis of the ellipse. If the ring gear is fixed and the eccentric on the drive shaft is turned clockwise, the Nidec tension shaft turnstransmission counterclockwise on the output side. The different number of teeth between the two wheels ultimately determines the respective speed.

The features in detail

- Gear ratios up to i = 120: 1

- different sizes

- precise

- torsionally stiff

- repeatable

- backlash free

- low starting torque

- light

Nidec is an exhibitor at Motek virtual and the FMB 2020.

Angular needle bearing and gear unit for robots and cobot

April 07.04.2020, XNUMX | Schaeffler Technologies is presenting two new components for use in lightweight robots and cobots. The new one Angular needle bearing XZU for robot and cobot joints and the new Precision gear RTWH for compact installation space.

April 07.04.2020, XNUMX | Schaeffler Technologies is presenting two new components for use in lightweight robots and cobots. The new one Angular needle bearing XZU for robot and cobot joints and the new Precision gear RTWH for compact installation space.

Installation kits with the highest torque density for handling systems

31.01.2018/2/XNUMX | The installation kit of the CSG-XNUMXA series of Harmonic Drive SE is suitable for highly dynamic applications. As a strain wave gear with lifelong precision, it offers zero backlash and the highest transmission and positioning accuracy, which is maintained over the entire service life due to the inherent preload of the gear.

Compared to standard wave gears, this series has the same dimensions 30% higher torque broken down into peak, nominal, average and collision torque. This means that higher accelerations and decelerations are possible in the application and the cycle times can be reduced. Alternatively, a smaller gearbox size can be selected for the same load. This allows for a more compact construction of the drive system than with standard strain wave gears.

Data exchange as the basis for digital twins

Data exchange as the basis for digital twins

With the collision torque increased by 30%, the CSG series from Harmoni Drive has a significantly increased robustness against shock loads compared to standard corrugated gears. However, the higher resilience of the gearbox does not come at the expense of the service life. On the contrary - the service life could be increased by 40% compared to the standard gear.

The installation kits CSG-2A series is available in ten sizes with gear ratios of 50, 80, 100, 120 and 160 with a repeatable peak torque of between 23 and 3419 Nm and a torque density of 260 to 545 Nm/kg. The fine graduation of the sizes makes it possible to select the most suitable gearbox size for the application.

Robot drives for the rapidly growing market

Robot drives for the rapidly growing market

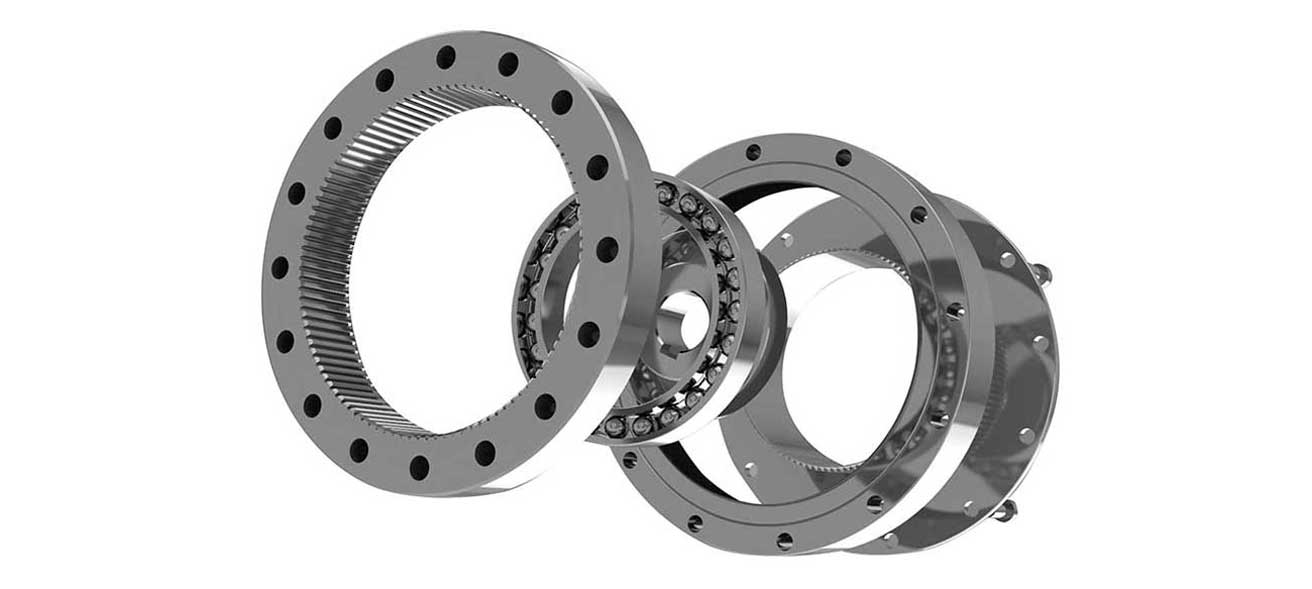

The installation kit, consisting of the components "Circular Spline", "Flexspline" and "Wave Generator", offers constructive freedom when integrating into the application. By using the existing housing structure, for example, a separate gearbox housing can be avoided. Furthermore, the bearing system of the application, which is already present, can often be used as the output bearing of the installation kit and the construction can be optimized for lightweight construction. The high torque density of the assembly kits of the CSG-2A series Harmonic Drive requires little space.

Functional principle and structure of a galaxy strain wave gear

13.04.2015/XNUMX/XNUMX | Like a galaxy strain wave gear from Wittenstein is set up and how it works is the content of this video:

The strain wave gear principle with Harmonic Drive

04.04.2023/XNUMX/XNUMX | That Harmonic Drive Gear is an invention of Harmonic Drive SE and the type of gear is a strain wave gear. The video illustrates the functional principle.

Frequently asked questions

- What is strain wave gear?

- How does a Harmonic Drive transmission work?

- What is the main advantage of Harmonic Drive gearboxes?

What is strain wave gear?

A harmonic drive is a simple but effective gear, which is used in all areas of drive technology and particularly often in robot technology. The harmonic drive offers, among other things, high efficiency and torque capacity. The harmonic drive is a combination of only three components: the wave (wave) generator, a deformable cylindrical steel bush called Flexspline and a ring gear called Circular Spline with internal teeth. By inserting the Wave Generator, the Flexspline takes on its elliptical shape. Due to the multiple teeth meshing continuously around the Flexspline and ring gear, the gearing runs without play, torsionally rigid and repeatable.

How does a Harmonic Drive transmission work?

A Harmonic Drive transmission uses deformable shafts to achieve high gear ratios with outstanding precision. The gearbox consists of three main components: an elliptical wave generator, a flexible ring with teeth and a rigid, toothed outer ring. The special interaction of these components creates a precise and compact drive solution.

What is the main advantage of Harmonic Drive gearboxes?

The main advantage lies in their outstanding precision and high Gear ratio with a compact design. Thanks to their unique construction, they offer almost play-free movement. This makes them ideal for applications where accuracy and reliability are paramount.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.