Data exchange in gear manufacturing as the basis for digital twins

- Details

- Hits: 7817

A complete virtual image of powertrains and gearboxes is only possible if gearbox, Rolling- and gearing specialists theirs simulation models digitally link with each other. Therefore, the cross-company and cross-system data exchange is one of the most important prerequisites for the generation of Digital Twins. Schaeffler and SEW have created such a data exchange.

A complete virtual image of powertrains and gearboxes is only possible if gearbox, Rolling- and gearing specialists theirs simulation models digitally link with each other. Therefore, the cross-company and cross-system data exchange is one of the most important prerequisites for the generation of Digital Twins. Schaeffler and SEW have created such a data exchange.

For the design and simulation of gearboxes, however, several specialized software and CAE tools have become established on the market. Each of these programs has its specific priorities. The problem: The exchange of gear data between manufacturers and their suppliers is often still manual and leads to complex duplication.

Plug-and-play gearbox kit for cobots and service robotics

Plug-and-play gearbox kit for cobots and service robotics

Schaeffler has now replaced this manual data exchange between the CAE tools with SEW-Eurodrive and the FVA (Forschungsvereinigung Antriebstechnik eV) with electronic data transmission using a standardized interface for transmission data. This eliminates the multiple modeling of gears. This greatly reduces development time and creates the basis for generating digital twins, which can be used, for example, to analyze operating data in the context of Industrie 4.0 solutions.

Standardized data format

Version 1.1 of the REXS (Reusable Engineering Exchange Standard) format offers uniform modeling and nomenclature for any gear with spur, bevel and planetary stages and its components. REXS is currently integrated in the FVA Workbench from version 5.0, in the Schaeffler rolling bearing analysis tool “Bearinx” in the current versions and in the gear calculation program “Wesilab” from SEW. Even providers of commercial CAE tools have already implemented the REXS interface or are planning to introduce it with the next release. With a click of the mouse, a REXS file is generated from the gearbox models.

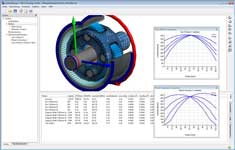

Gear calculation for gears with background graphic

Gear calculation for gears with background graphic

Schaeffler is now offering the automated exchange of transmission data using the REXS interface. Users receive calculation results from Bearinx much faster and thus significantly accelerate their development process. Stephan Evert, Head of Bearing Analysis Tools Development in the R&D Bearings division at Schaeffler, emphasizes the advantages: “With the help of REXS, we can reduce the effort involved in the software-technical coupling of CAE tools and simulations, while at the same time simplifying the IT architectures ", And further:" REXS can be used by the transmission industry as a standardized data container for generating digital twins. "

Accelerated application development

Transmission manufacturers with a large proportion of customer-specific application development benefit greatly from digitized data exchange with their suppliers. "The goal is to be able to efficiently and effectively use different systems with their own computational focus", Dr. Heinrich Bolz, Head of Calculation and Simulation in Development Gearboxes at SEW-Eurodrive, explains about the open-source project: "With REXS, transmission data can be transmitted quickly and without errors. The interface thus makes a significant contribution to optimizing our innovation process. "

Measuring torque with sensors inside the transmission

Measuring torque with sensors inside the transmission

The REXS interface is license-free at www.rexs.info. There you will also find all other information about the current and future development. At the Schaeffler booth, visitors can see for themselves how easily the data models can be exchanged between CAE tools.

You might also be interested in...

Profile rail guide using modern foundry technology from Laempe

Artificial Intelligence | trends and developments

spindle bearing | The Vacrodur high-performance elements

linear guide | Precise, light, durable

Additive manufacturing on multi-material 3D printers