Cochlear Implant | I hear you well!

- Details

- Hits: 8186

Cochlear implants are revolutionary Hearing aidsthat can restore hearing for people with severe hearing loss, including deafness. They convert sound into electrical impulses, which the brain interprets as sound. This article provides an in-depth look at the impressive technology behind the cochlear implant and how it works, such as through the 3D microprint or thread forming screws.

Contents

- How a MED-EL cochlear implant works

- 3D printed microstructures improve cochlear implants

- Microscrews support cochlear implant technology

According to the World Health Organization (WHO), in 2019 approx. 466 million people bad and thus more than 5% of the world population suffer from hearing loss. One way towards active participation in social life for people who are hard of hearing, severely deaf or even deaf, for those who find little or no improvement with conventional hearing aids, can be Oticon Medical's cochlear implant technology. This has been continuously improved since it was developed in the 60s, as the following examples show.

How a cochlear implant works

17.07.2023 | MED-EL, Austrian manufacturer of hearing implants, opens the door for people to be able to hear again with its innovative solutions. The Synchrony cochlear implant is placed in the cochlea of the inner ear and under the skin. The video clearly shows how the hearing system works.

3D printed microstructures improve cochlear implants

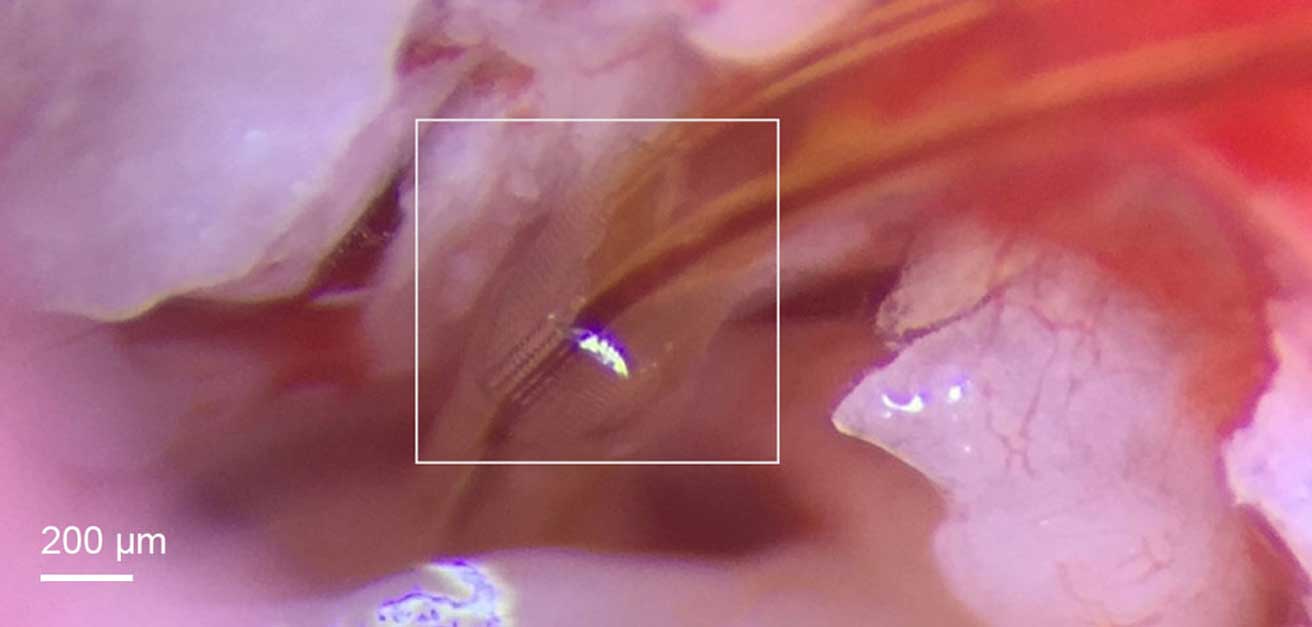

27.01.2020/3/XNUMX | Scientists have based on the XNUMXD microfabrication of microstructures from Nanoscribe developed a new type of cochlear implant. Microstructures produced using 3D printing release steroids via the smallest structures. With this, the researchers are bringing together a high-precision 3D printed steroid reservoir and a 2D MEMS-based electrode array for the production of new cochlear implants for the first time. The cochlear implant design was designed to reduce residual hearing damage from lead insertion trauma.

Some patients have a severe hearing loss damaged hair cells in the inner ear (cochlea). In this disease, the auditory nerve can be stimulated with cochlear implants. The cochlear implant is a hearing aid for the ear of the deaf and deaf, whose auditory nerve is still functional as part of the auditory perception.

Virtual reality for the treatment of mental disorders

Virtual reality for the treatment of mental disorders

An international team of bio-scientists from the Bio-Microrobotics Laboratory of the Daegu Gyeongbuk Institute of Science and Technology (DGIST) developed a in collaboration with the Microsystems Lab of the Swiss Federal Institute of Technology Lausanne (EPFL) and Ajou University novel cochlear implant. It protects the patient's remaining hearing ability from damage caused by the introduction of electrodes.

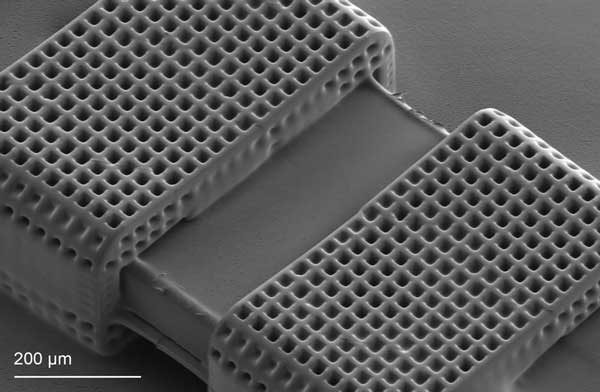

With the Photonic Professional systems from Nanoscribe, the scientists porous microstructures manufactured. These were mounted on an electrode array. They have shown that the cochlear implants stimulate the auditory nerve. Using guinea pigs, the researchers have shown that the 3D-printed micro-reservoirs constantly release steroids locally and can thus be proven to protect the residual hearing.

High-precision support of cochlear implants

The cochlea electrode array with microstructures is a flexible 2D electrode array based on the microelectromechanical system technology MEMS. It is said to trigger electrical stimulation of the auditory nerve in the brain. The MEMS based electrode was built up with several individual microscopic porous 3D structures that contain steroids and release them in a targeted manner.

The cochlea electrode array with microstructures is a flexible 2D electrode array based on the microelectromechanical system technology MEMS. It is said to trigger electrical stimulation of the auditory nerve in the brain. The MEMS based electrode was built up with several individual microscopic porous 3D structures that contain steroids and release them in a targeted manner.

The high-precision 3D microstructures were created using Two-photon polymerization manufactured using the Solution Set Medium feature. This made it possible to produce the porous structures in micrometer size. The versatile one 3D Print from Nanoscribe enabled the geometrically exact production of the microstructures with the required dimensions and the coating of a large, porous surface with steroids.

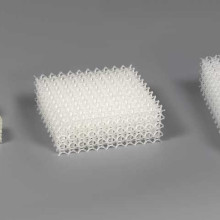

Micro 3D printing in life sciences

The diversity of 3D microfabrication enables complex microstructured parts to be materialized with extraordinary precision. The micro-parts can be designed according to the requirements in the life sciences. Cell frameworks, micro stents or micro needles can be produced in this way.

Adaptive exoskeleton for the stroke patient

Adaptive exoskeleton for the stroke patient

Printing materials also have a great influence on the properties of the final 3D print objects. With a view to the requirements of microfabrication, Nanoscribe researches a wide variety of material compositions and develops, among other things, biocompatible photoresists.

Microscrews support cochlear implant technology

11.06.2020/XNUMX/XNUMX | If conventional hearing aids are not successful enough for people who are hard of hearing or even deaf to participate in social life again, Opticon Medical's cochlear technology can help. The self-defending ones screws from Ejot ensure a permanently secure connection.

The cochlear implant is an electronic medical device that performs the function of the damaged inner ear. Unlike hearing aids, which only increase the volume of sounds, cochlear implants take over the function of the damaged part of the inner ear (the cochlea) to transmit audio signals to the brain.

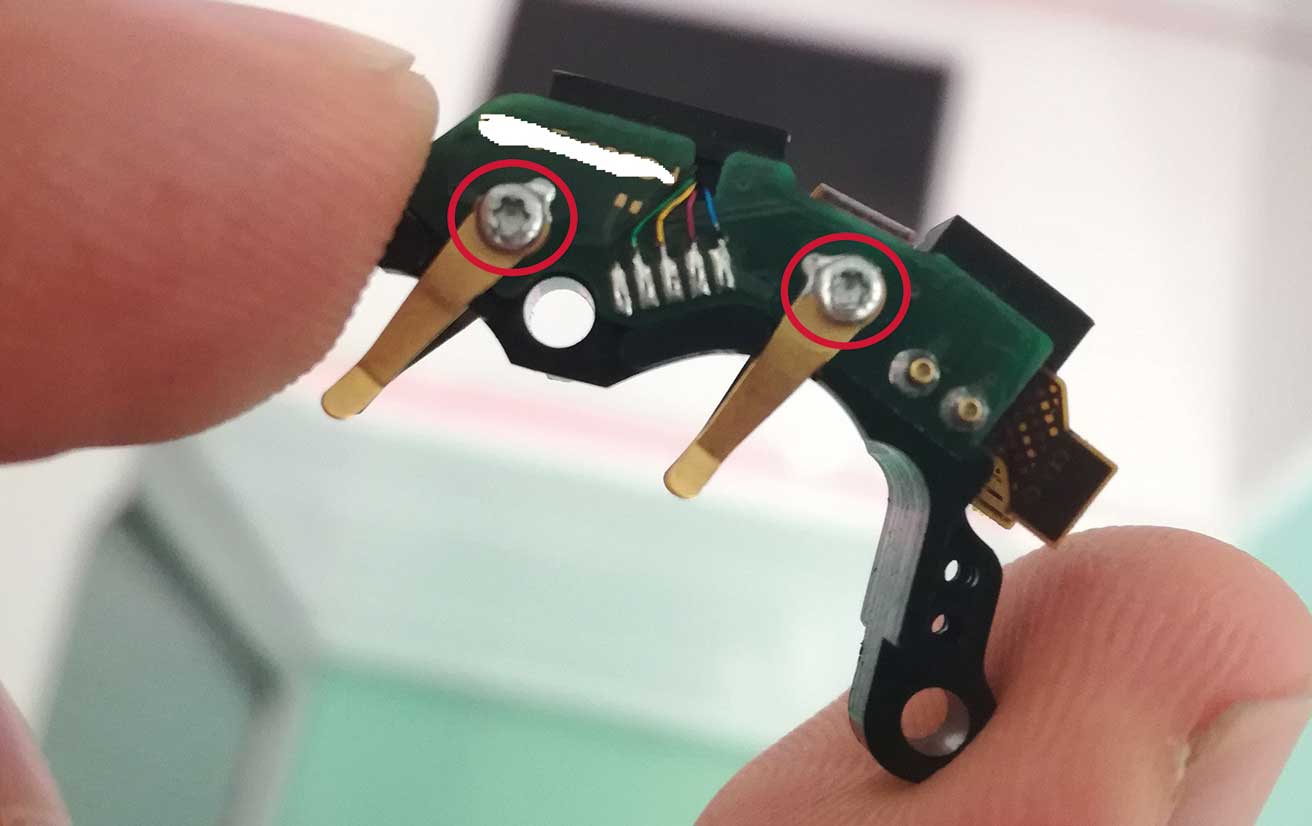

With the NeuroOne Global specialist Oticon Medical has launched a new generation of sound processors that combine the latest benefits of hearing aids and cochlear implants. The advanced technology enables an analysis of the listening environment and thus automatically adapts to new listening environments. In addition to a large number of automated functions, innovative signal processing and user-friendly Bluetooth technologies, this ensures clearer sound and the best speech and hearing comprehension.

Self-tapping screws

![]() Even with the one used Hardware Oticon Medical relies on the highest quality. The modern and customizable design of the Neuro One is extremely robust and meets the highest security requirements. In addition to the materials used, the connection technology used plays a key role in ensuring a long service life.

Even with the one used Hardware Oticon Medical relies on the highest quality. The modern and customizable design of the Neuro One is extremely robust and meets the highest security requirements. In addition to the materials used, the connection technology used plays a key role in ensuring a long service life.

When screwing the circuit board to a plastic carrier, Oticon relies on self-tapping screws from the connection technology specialist Ejot. The Delta PT screws used in this area of application are designed for the highest loads and ensure a permanently secure connection, even with daily exposure to vibrations and shocks.

Special thread geometry

The special thread geometry of the Delta Pt screw is the result of a consistent analysis of material displacement during thread forming. The flank angle of this screw allows a reduction in radial expansion compared to conventional thread flanks. It generates only a small amount of radial expansion, so that very thin-walled constructions can be implemented, as is the case with the Neuro One application. The optimized pitch of the screw was determined by the balanced ratio of the highest possible preload force with low surface pressure in the plastic.

Efficient from direct screwing to screw drive

Efficient from direct screwing to screw drive

It thus enables a very high thread overlap, even with small screw-in depths. The result is a particularly high connection performance of this special connection element.

Micro screw with 1 mm diameter

Due to the very compact design of the Neuro One, the connection solution used was implemented with minimal installation space. Under these special conditions, the Delta PT had to be micro screw be laid out. The tiny screws used, with a diameter of just 1 mm, have all the advantages of the larger dimensions, in particular a high mechanical strength of the connection due to the self-tapping property.

Due to the very compact design of the Neuro One, the connection solution used was implemented with minimal installation space. Under these special conditions, the Delta PT had to be micro screw be laid out. The tiny screws used, with a diameter of just 1 mm, have all the advantages of the larger dimensions, in particular a high mechanical strength of the connection due to the self-tapping property.

In contrast to metric screw connections, where there is always a defined tolerance in the thread pairing, the direct screw connection used here achieves maximum strength thanks to the tolerance-free thread. The benefit of this Freedom of play weighs proportionately greater the smaller the connection is designed. Thus, even in the micro range, a permanent, very durable connection is always ensured.

The thread-forming miniature screws also save the additional operation of the previous thread cutting, which is much more difficult with smaller screw dimensions than larger dimensions. Furthermore, there is no need for the high tool wear that results from metric screw connections due to the necessary thread cutting. Thus, cost-saving potentials can be exploited when using the micro-screws.

General technical knowledge

What is a cochlear implant?

A cochlear implant is an electronic medical device that can replace or improve the function of the damaged inner ear. It enables people with severe hearing loss or deafness to perceive sound. Unlike hearing aids, which only amplify sound, a cochlear implant converts sound waves into electrical impulses that are sent directly to the auditory nerve and interpreted by the brain as sound.

Development of the cochlear implant began in the 1960s. dr William House, an American otolaryngologist, is often considered the "father of the cochlear implant". He developed the first working implant, which was first placed in a patient in 1961. However, the US Food and Drug Administration (FDA) only approved cochlear implants for adults in 1984 and for children in 1990.

The market penetration of cochlear implants has steadily increased since their invention. According to the World Health Organization (WHO), in 2019 there were around 500.000 users with CI fittings worldwide.

You might also be interested in...

screw connection | Well connected!

Reduce carbon footprint | That's how it's done!

3D microprinting based on two-photon polymerization

Secure thin sheet connections with pilot hole

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.