Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

Image processing for quality assurance

Embedded vision, Gig-E and 3D cameras, frame grabbers, CMOS sensors, etc. to avoid errors and determine position

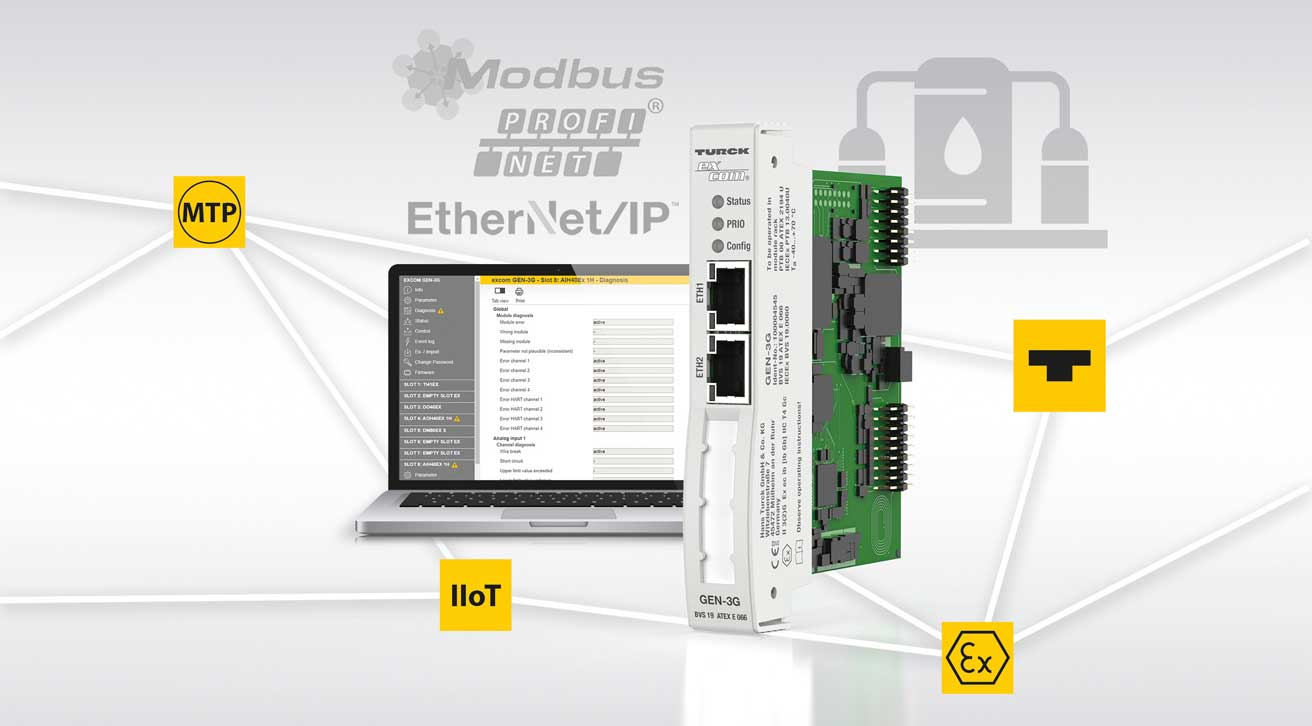

Communication: Technology for Industry 4.0

Gateways, switches, networks, standards such as Ethernet Ethercat, OPC UA or IO-Link and much more for digital transformation

Image: Pepperl + Fuchs

IPC for manufacturing and production

HMI, smartphone, tablet, mobile phone, monitor and accessories for harsh industrial environments and hazardous areas

Image: Ecom

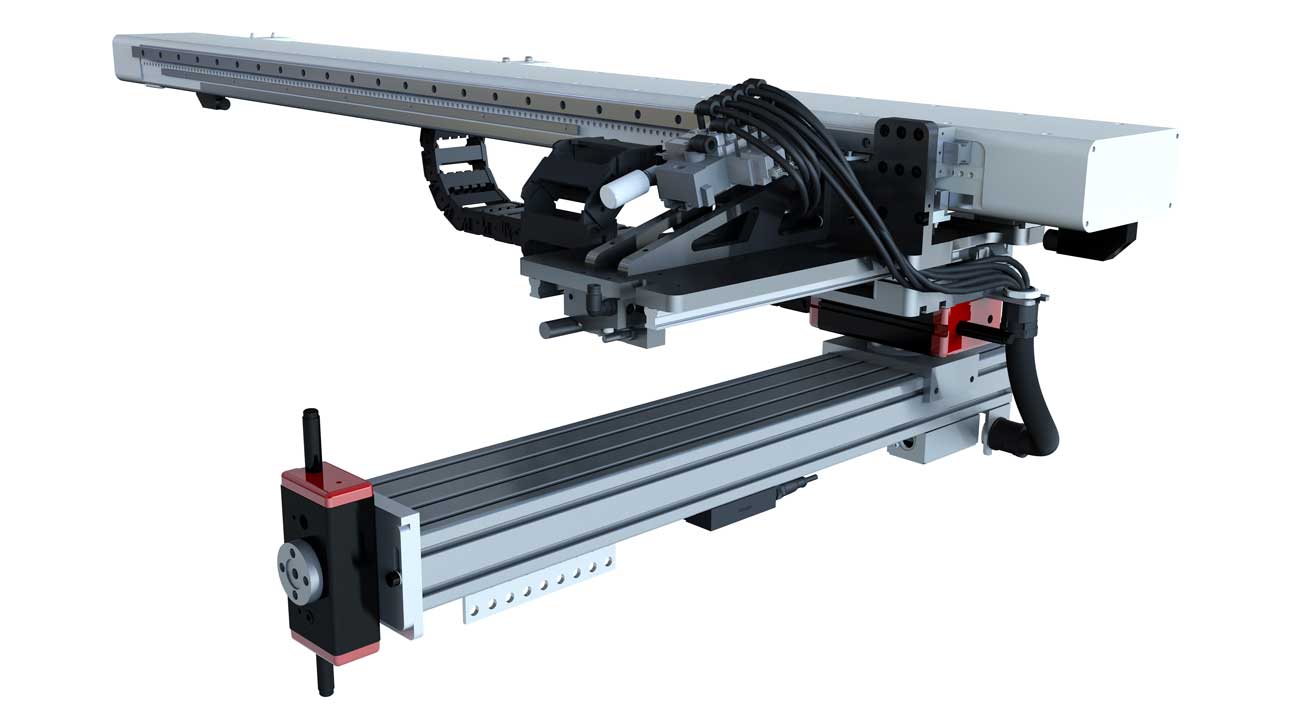

Robots for the automated factory

Articulated robots or Scara robots, bionic, assembly, service robots and the collaborative cobots as well as grippers and accessories

Image: Mitsubishi Electric

Sensors for the Internet of Things

Safety sensors, torque sensors, optoelectronic sensors or magnetic sensors, also for various types of protection

Safety technology for man-machine protection

Light grid, light barrier, safety interlock, safety light curtains, safe field box, signal lights for occupational safety and machine safety

Controls for mechanical engineering

Programmable logic controls, CNC controls, TNC controls or safety controls with digital twin and control technology

Here you will find numerous innovations from the industrial sector Automation services for the Industry 4.0 Age. We provide information about components, systems of the Image Processing, IPC, communication technology, Robot, Sensors Safety Technology and Controllers. We report on processes and technologies which the industrial Revolution serve in the world of work. In these automated processes, workplaces are becoming increasingly automated, freeing up manpower for less monotonous work.

Contents

Artificial intelligence is increasingly finding its way into the world of work and advancing automation technology. The products, systems, machines and plants for automation are networked with each other up to completely autonomous machines as part of the larger whole smart manufacturing. Our coverage shows the components, systems and applications of automation technology for process and factory automation from the sensor to grab, Communication technology, control and regulation technology, IT up to and including robots.

Special industries like Automotive industry, Renewable energies, Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery require specially designed developments and knowledge. Here we introduce you to the latest innovations. You will also find news from and for the here Applied research.

The automation technology also forms Electrical Engineering, Drive Technology and other engineering scientific disciplines form the basis of such buzzword-rich developments as Industry 4.0, digital transformation or smart factory, which is particularly important in... Industrial machinery and equipment change our industrial production and manufacturing forever at a rapid pace. The following innovations are part of the bigger picture:

Igus presents the Service robot Rebel. Just one year after the first presentation of the modular gearbox for cobots, igus is already recording 20 automation projects per week. In doing so, igus relies entirely on its Motion Plastics expertise: the use of plastic makes the robot, weighing 8,2 kg, the lightest service robot with cobot function in its class. All mechanical components in the Rebel are developed and manufactured by igus.

Igus presents the Service robot Rebel. Just one year after the first presentation of the modular gearbox for cobots, igus is already recording 20 automation projects per week. In doing so, igus relies entirely on its Motion Plastics expertise: the use of plastic makes the robot, weighing 8,2 kg, the lightest service robot with cobot function in its class. All mechanical components in the Rebel are developed and manufactured by igus.

Get on the plane and just a few hours later get off again thousands of kilometers away: Airplanes take us to almost any place around the world. Innovative scan technologies from Pepperl + Fuchs can help ensure that an aircraft is not only comfortable, but above all safe.

The entry of Cobots or collaborative robots into the production halls is in full swing. This revolutionary Robotic-Technology works hand in hand with people and optimizes work processes. Discover the exciting world of cobots and their diverse applications in industry and everyday life here.

The start-up Rovi RobotVision by three researchers Technical University of Munich has made it its mission to significantly simplify the hardware for robots of all kinds: Based on their research, the team has succeeded for the first time in the world in using expensive traditional electronic Sensors to be replaced with new software and common cameras. Because of the direct control option of the Motors used the inventors grab from Gimatic.

A pair of capacitive sensor is used wherever precise measurement results are required. Due to the very good temperature stability, the capacitive measuring principle is particularly suitable for applications in which temperature fluctuations appear. Other sensor technologies such as laser sensors, which record a strong temperature drift in the signal, are also interesting. The capacitive sensors from Micro-Epsilon are often used for quality assurance in the process or as measurement sensors for complete control loops. The sensors measure vibrations, deflection, expansion, path, deflection, deformation, thickness and much more.

Industry 4.0 based primarily on the Communication of all components involved from the temperature sensor to the process plant. Of the fieldbus connects them all to the IT world. Protocols determine who can and should communicate what, when. There are around 50 different fieldbuses that network technology make it very diverse. We report here on new products, maintenance and applications of these communication systems.

In logistics, care, kitchens, bars or in the fields: the potential for service robotics is great. Cobots take on monotonous and non-ergonomic tasks here. For the simple, cost-effective implementation of such lightweight robots Igus an Gearbox kit for cobots. The focus is on the fully integrated Tribo strain wave gear with motor, absolute value encoder, force control and controller. Deployed in Service robot Rebel Igus now accelerates the Low Cost Automation. Here you can find out what's new about the cobot and gearbox:

Ordered ten years ago Geiger handling with the parallelgrab MHZ2-16 D for the first time a product of the company Gimatic. At that time, the handling specialist was looking for a reliable and competent partner for components that, among other things, were used in the Plastic manufacturing industry should be used. Over the years, a collaboration has developed that can be described with a clear conscience as a win-win partnership.

With Artificial intelligence (AI) you are also smart beforehand. Mitsubishi Electric puts his corporate AI now also for Predictive Maintenance in machines, systems and robots. Thanks to real-time analysis technology for recorded operating data, maintenance reaches a new level. Maintenance needs are identified early, before they arise. In this way, necessary measures can be planned in advance and reduced to a minimum. You can find an overview of the condition monitoring solutions below:

How far the coordination of production and the MES / ERP world can already be achieved on the way to Industry 4.0 is shown by the joint IoT solution from SAP and Mitsubishi Electric, Customers of the automation specialist can directly contact the cloud platform of the Partners connect SAP.

How far the coordination of production and the MES / ERP world can already be achieved on the way to Industry 4.0 is shown by the joint IoT solution from SAP and Mitsubishi Electric, Customers of the automation specialist can directly contact the cloud platform of the Partners connect SAP.

Turck offers controls for controlling and monitoring such as the IP67 PLC with cloud connection and edge gateway function, Ethernet gateways also for that hazardous area and HMI operator panels. Here we present the new developments:

The Schmersal Gruppe offers the modular, programmable safety controllers of the series for safe signal processing ProtectPSC and the multifunctional safety controls with program selection functions of the ProtectSelect Line. Both offer options for the visualization and diagnosis of signals. We present you here new developments from the field Safety control for safety applications:

Remote service solutions for remote maintenance and service purposes have prevailed across the board. With the concept of a digital twin comes for Harting Now the next logical step: The virtual representation of systems installed around the world makes service calls easier and creates new possibilities for, for example Condition monitoring.