Igus | The motion plastics specialist

- Details

- Hits: 46566

What's up at igus? The motion plastics specialist is presenting the new business figures at the Hannover Messe 2024 247 news before. The Motion Platics specialist also follows up with the Igus Go app the goal of advancing Zero Lubrication. You can find this and other news from Igus below:

Content:

- Annual report 2023, 247 new products and Igus Go app

- Igus supports the Sailwind 4 project at Konstanz University

- Igus supports Rheinkrake in collecting plastic waste

- Specially developed hall heating concept free of charge for everyone

- Enjoyneering digital with 190 new products

- Igus finances collection of plastic waste in Indian rivers

- Igus acquires majority stake in Commonplace Robotics

- Business award for sustainability

- Business result 2021: Record year exceeded

- Archive for Igus News

- Who is Igus?

Annual report 2023, 247 new products and Igus Go app

16.04.2024 | EUR 1,136 billion turnover, 6,7% more customers and 247 new products for the Hannover Messe: This is what Igus is presenting in spring 2024. In 2023, Igus was able to increase the number of its active customers by 6,7% and increase annual sales by only a small minus of 1,65 despite the tense global economic situation .XNUMX% compared to the previous year.

16.04.2024 | EUR 1,136 billion turnover, 6,7% more customers and 247 new products for the Hannover Messe: This is what Igus is presenting in spring 2024. In 2023, Igus was able to increase the number of its active customers by 6,7% and increase annual sales by only a small minus of 1,65 despite the tense global economic situation .XNUMX% compared to the previous year.

“Economic-related declines in regular customers were largely offset by new customers and new applications. We are confident that we will continue our growth in 2024. The first quarter was comparatively difficult, but the annual forecast for 2024 is good,” says Tobias Vogel, Managing Director of Plain Bearings and Linear Technology at Igus.

In 2024, the motion plastics specialist will invest in 247 new products and digital services. The focus is on cheaper and better solutions for lubrication-free movements, low-cost automation and CO2-reducing products.

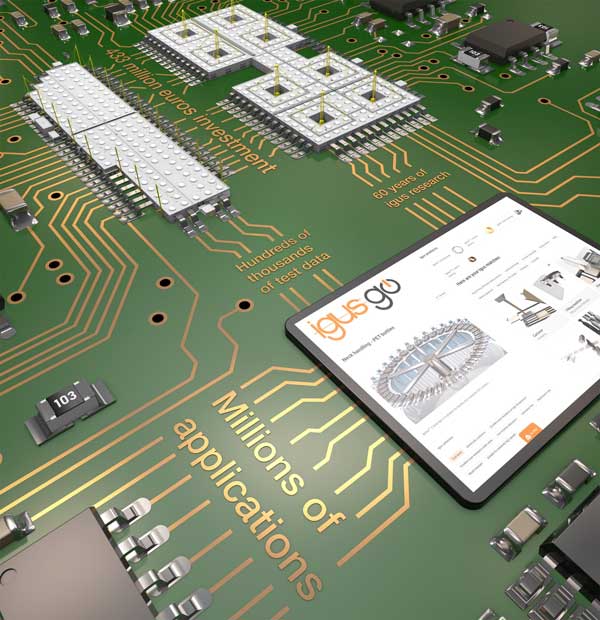

The use of Artificial intelligence (AI) when bundling hundreds of thousands of test data and millions of applications from 60 years of know-how leads to the simple solution finder Igus GO app with the Zero lubrication-Goal.

Zero lubrication goal in focus

High-load bearings for heavy machinery, among other things, are crucial for the “Zero Lubrication” offer. Three new materials are coming onto the market from stock that have already proven themselves among users such as excavator manufacturers. “'Igus, degrease the excavator!' you can use voice control in the Igus GO app already implemented today,” says Tobias Vogel. “This is where material technologies and artificial intelligence come together to provide easy and secure access to millions of pieces of evidence for all industry professionals in the world via AI chat.”

EUR 433 million Investments In the last three years, around half were made in Germany. The long-term corporate strategy envisages constantly expanding the Motion Plastics product world with the aim of “improving what moves”. After breaking through to its first billion euros in sales in 2022, the company specified its new goal: one million buying industrial customers per year. At that time, that meant a roughly 5,5-fold increase.

“We are therefore pleased that we have at least come a little closer to this goal in a difficult year in 2023,” said Michael Blass, Managing Director of E-Chain Systems. “The 210 million euros at the Cologne location include the new 22.000 square meter factory, new machines, systems and IT innovations such as the GO Zero Lubrication apps. The number also includes a strategic doubling of global inventories of catalog parts. “Despite all the technical revolution, customers want to receive deliveries within 1-3 days, and at reasonable prices,” explains Mr. Blass.

Investments continue at the same pace. New machines and automation solutions are purchased for the new factory in Cologne. Many of the internal start-ups settle there and train Motion Plastics Tech Center. In addition, the conversion of a 2.800 m2 large office building into another start-up and training center, also for customers.

Igus supports the Sailwind 4 project at Konstanz University

Oct 09.10.2023, 4 | Igus supports the Sailwind XNUMX project run by students at the HTWG University of Konstanz. The students of the HTWG University of Konstanz – In their Sailwind 4 project, technology, business and design rely on small windmills to generate green electricity.

Oct 09.10.2023, 4 | Igus supports the Sailwind XNUMX project run by students at the HTWG University of Konstanz. The students of the HTWG University of Konstanz – In their Sailwind 4 project, technology, business and design rely on small windmills to generate green electricity.

Igus supports Rheinkrake in collecting plastic waste

Oct 09.10.2023, XNUMX | Intercepting plastic before it ends up in the sea: This is what the Rheinkrake initiative does, which is supported by the plastics specialist Igus. Cologne's floating garbage trap Rhine Cleanup Command Unit (KRAKE eV) fishes waste out of the Rhine around the clock.

Oct 09.10.2023, XNUMX | Intercepting plastic before it ends up in the sea: This is what the Rheinkrake initiative does, which is supported by the plastics specialist Igus. Cologne's floating garbage trap Rhine Cleanup Command Unit (KRAKE eV) fishes waste out of the Rhine around the clock.

Specially developed hall heating concept free of charge for everyone

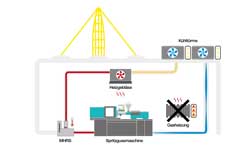

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat their industrial halls with machine waste heat and thus reduce gas costs and CO2-emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat their industrial halls with machine waste heat and thus reduce gas costs and CO2-emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

Enjoyneering digital with 190 new products

18.04.2023/XNUMX/XNUMX | Even though Igus has been faced with the challenges of the pandemic, the Ukraine war and the energy crisis in recent years, the Cologne-based company did not let this stop it from growing. The company now employs around 4600 employees at 31 locations and serves over 188.000 customers from over 50 industries worldwide. After exceeding the one-billion mark in sales for the first time in November 2022, annual sales in 2022 rose by a total of 25% to EUR 1,15 billion.

Playfully to engineering peak performance from the absence of lubricants via app and online low-cost automation to digital CO2-Reduction he's waiting Enjoyneering Igus booth at the Hannover Messe on. With 190 real and digital product innovations, the motion plastics specialist is driving Next Level Engineering and has set itself high goals.

Igus is on its way to its millionth customer

Until 2030 the plastics specialist now wants to look after one million active customers worldwide. In order to achieve this goal, igus continues to invest heavily in the development of innovative motion plastics and in fast on-site delivery. The focus is always on making moving applications with energy chains, plain bearings, ball bearings, cables, 3D printing services or robots light, lubrication-free, robust and durable all over the world.

With many Online-Tools the service life of the igus products can be clearly predicted. This predictability enables users to Machine Elements optimally matched to each other in terms of a sustainable overall service life of the applications. That goes for featherweight ones bearings as well as for energy chain systems for kilometers of travel.

At the digital stand, igus shows the possibilities of the virtual parallel world. Visitors can put on VR glasses and step into virtual reality by using a Robotic arm steer. The robot stands right next to them and reflects the movements in real time. With this, igus gives a foretaste of what is to come in the future Iguverse will be possible. That's what the people of Cologne call their Igus Metaverse.

Igus finances the collection of plastic waste in Indian rivers

18.03.2023/1000/XNUMX | Most of the millions of tons of plastic that enter the oceans every year are washed from land into the seas by more than XNUMX rivers. Plastic fishermen is a non-profit organization that fights against environmental pollution. The company has been collecting since 2021 Plastic waste from rivers in Indonesia and India.

18.03.2023/1000/XNUMX | Most of the millions of tons of plastic that enter the oceans every year are washed from land into the seas by more than XNUMX rivers. Plastic fishermen is a non-profit organization that fights against environmental pollution. The company has been collecting since 2021 Plastic waste from rivers in Indonesia and India.

Igus acquires majority stake in Commonplace Robotics

29.09.2022/XNUMX/XNUMX | igus is investing in the expansion of its activities in the Low cost automation. In addition, the Motion Plastics provider has the majority shares in Common Place Robotics based in Bissendorf near Osnabrück. The company specializes in the integration of intuitive controls, software and power electronics for the Industrial robots and robotics in education.

Both companies have been working together intensively for six years. Among other things, they developed the igus Robot Control (IRC) together. The steering complements the low-cost kinematics made of high-performance plastics.

dr Christian Meyer founded the company Commonplace Robotics eleven years ago with the aim of making the integration and operation of robots so cheap and easy that they can be used anywhere (commonplace). Both companies have since developed products such as the IRC and the Rebel Cobot, as well as an actuator.

Solve robot tasks in 30 minutes

"Many customers are surprised that they can implement simple robot tasks in just 30 minutes without any programming knowledge," says igus Managing Director Frank Blase. "We are very pleased that after the intensive cooperation of the last six years, an even more focused approach to low-cost automation is now possible."

dr Christian Meyer comments: “We look forward to exciting technological projects with igus. New requirements from customers from all areas of industry come to our laboratories every day, especially via the RBTX platform for low-cost robotics. Much of this can be implemented quickly, especially since we will be expanding with the investment.”

The latest product of the cooperation is the Rebel Cobot. The actuator is also available as a single component. It combines igus' knowledge of plastics in the gearbox with power electronics and software from Commonplace Robotics. With six axes, the Rebel handles a payload of up to 2 kg with a reach of 664 mm and a dead weight of only 8,2 kg.

Business award for sustainability

19.09.2022/XNUMX/XNUMX | For its recycling program chainge igus was awarded the Rhineland Business Prize for the plastic energy chains. Igus was able to convince the jury in the sustainability category.

19.09.2022/XNUMX/XNUMX | For its recycling program chainge igus was awarded the Rhineland Business Prize for the plastic energy chains. Igus was able to convince the jury in the sustainability category.

Chainge preserves those used in many industrial machines and plants worldwide e-chains made of high-performance plastic before incineration and gives them a second life. Customers can send their disused energy chains to the manufacturer, who will even take back E-chains from competitors. In return, customers receive a voucher, the amount of which is determined based on the weight of the chain submitted.

Since 2019 have been so already collected over 52 t and sent for recycling. But that's not all: Based on the recycling program, e-chains are also made from 100% recycled material.

Business result 2021: Record year exceeded

22.03.2022/188.000/XNUMX | Igus has that thanks to XNUMX active customers Record year exceeded, increases its ability to deliver and grows by 32%. From the drive line to the Gear a very high proportion of customers ordered Motion Plastics products in 2021. The 2019 plan to invest in production and supply chain helped.

In this way, the rapidly increasing demand could be served. Also with a view to the Ukraine conflict, the expansion will continue until 2023. The corporate goal "Improve what moves; CO2 Neutrality, without plastic waste and "become the easiest company to deal with." could gain in sharpness.

Everything produced and procured in-house

"234 million euros more sales in one year with almost the same sales prices by the end of the year, and everything we produce and procure ourselves - we've never had that before," says the managing director. “Our colleagues have worked miracles. And we were lucky that we implemented our investment plans even in the bad year of 2020.” Sales in 2021 amounted to 961 million euros.

MinebeaMitsumi Newsticker company news

MinebeaMitsumi Newsticker company news

32% more sales than 2020 also mean 26% more than in the record year 2019. This year, the people of Cologne started implementing their plan, which was internally known as "No. 1 Catalog” means: Since then, more than 80.000 articles have been in stock in larger quantities. The 15 distribution warehouses worldwide have increased the number of catalog products that are shipped on the same day or within 24 hours to at least 25%.

"That's probably why the sales growth is almost the same in all product lines," says the managing director. Also the Online-Shop Pages have been expanded. Sales here increased by 55% in 2021.

A total of 500 new injection molding machines

The Ukraine war and the shortages in many markets are causing even more to be invested in the short term material availability to invest. In parallel, the Production capacities increased. Since 2020, production has been expanded or modernized by 300 injection molding machines. Another 200 machines have already been ordered. The new production building with an additional 20.000 m² of space is expected to be completed on May 1, 2023.

New storage locations for 2021 pallets were already built in 12.000. The company is currently planning the next expansion of the "Igus Campus Cologne". Adjoining areas with a total size of 20.000 m² were acquired for this purpose. The 35 foreign subsidiaries have expanded to 60.000 m² of floor space.

Against the lack of chips: the performance center will be continued

Against the lack of chips: the performance center will be continued

Customers from over 50 industries consistently approach igus with new challenges. The example of clean room cables for chip production makes this clear: "New flexible cable feeds such as the E-skin flat are required above all in the fast-growing semiconductor industry," says Peter Mattonet, branch manager clean room. "Replacing a line in minutes is a revolution in manufacturing and increases much-needed output."

5000 do-it-yourself engineering daily

Also in the second year of Home office and remote work the speed of innovation in Cologne has not slowed down. The result is a total of 168 product developments, such as the injection-moulded Motion Plastics gear wheels and 740 different items in the online shop.

The four-year Smart Plastics business unit launched twelve new products in 2021 for preventive maintenance, condition monitoring and IoT to market. Together with the line monitoring of Ethernet lines in real time and the integrated solar-powered condition sensor EC.I, users can now completely avoid unexpected system downtimes.

Low-cost robot Integration via online advice and with a fixed price: This is made possible by the new Digital + Mensch service RBTXpert. In a 400 m² customer testing area, igus experts check customer requirements before an offer is made. A typical solution costs 8500 euros in hardware and requires 20 hours of integration.

The offer is already available in seven countries, and a further 14 countries are in preparation. With the three new online tools, a total of 58 product finders, calculation programs, design and simulation tools, etc. are now available.

95% carbon neutral in a smudge-free world

On the way to climate-neutral production by 2025 various projects were tackled in the past year. As of today, 95% have been achieved according to Scope 1 and 2 (Greenhouse Gas Protocol). 100 older injection molding machines were exchanged for 40% more energy-efficient machines. Energy management has been further optimized and an ISO certificate will follow at the end of March.

Mayr drive technology: News from Mauerstetten

Mayr drive technology: News from Mauerstetten

In addition, igus has planted 15.687 trees in 23 countries and reduced non-recyclable plastic waste in production by 21%. The global e-chain recycling program Chainge has grown in recent years and is operated internationally. In the spring of this year, the first energy chain made from 100% recycled materials will be launched.

Who is Igus?

The Igus GmbH develops and produces Motion Plastics, their trademark lubrication-free high-performance plastics. It was founded in 1964 in a garage in Cologne and broke the one billion mark for the first time in 2022. The Motion Plastics are processed to Energy supply, highly flexible cables or Lines, plain bearings, Linear bearings and thread technology.

The family company based in Cologne is represented in 31 countries and employs 4600 people worldwide. In recent years, the company has also expanded through internal start-ups such as ball bearings, Robots, gears, 3D pressure Service, lean robotics and smart plastics for Industry 4.0.

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

linear guide | Precise, light, durable

The author Oliver Cyrus is Head of Press + Advertising at igus GmbH in Cologne.