Sustainability plastics – CO2 neutral with recycling

- Details

- Hits: 5285

The importance of sustainability in the plastics industry is growing. Recycling is becoming more and more important. Companies like Igus are increasingly focusing on environmentally friendly solutions and contributing to changing the plastics industry. The motion plastics specialist shows how the use of high-performance plastics can have a positive impact on the circular economy. Read how sustainable plastics and their production CO2-neutral can be.

Contents

- Igus and the circular economy

- Sustainable products from sustainable production

- Projects, support and investments for nighttime

- FAQ

Igus and the circular economy

“We know about the great possibilities that plastic has. Our tribopolymers are used millions of times in moving applications all over the world, reducing weight, maintenance and lubrication,” says Owner Frank Blase. "We are working to ensure that plastic, through almost 100 percent recycling, becomes a material that does not harm our world, but helps."

“We know about the great possibilities that plastic has. Our tribopolymers are used millions of times in moving applications all over the world, reducing weight, maintenance and lubrication,” says Owner Frank Blase. "We are working to ensure that plastic, through almost 100 percent recycling, becomes a material that does not harm our world, but helps."

Plastic as a versatile material

But what exactly makes plastic so interesting for industrial use? The main advantages are:

- lubricant are not additionally required.

- Low friction, because the special plastic recipes include solid lubricants, among other things.

- small Weight: A plain bearing made of plastic weighs up to 75% less than one made of metal of the same size.

But at Igus we know that not every part is perfect Metal can be replaced across the board with plastic. Before designers receive a recommendation, all operating conditions are checked. The manufacturer also offers many Online-Tools, with which interested parties can view and order suitable products.

Millions of tons of plastic waste

Up to 22,7 million tons of detached fats pollute the environment worldwide every year. According to estimates, 80 million tons of plastic waste have currently accumulated in the world's oceans alone. Eight million tons of plastic are added every year. In addition, a large proportion of plastics are burned. Only around 14% of global packaging waste is recycled. Not only the economic loss of 80 billion US dollars per year, but also the continuous production of new plastic from fossil fuels are issues to consider. Because they are accompanied by high CO2 emissions. That requires 6% of global oil production today, which to 2050% by 20 will rise.

The benefits of plastic can be diverse and sustainable and that is why for Igus GmbH from Cologne it is not just a material, but a technology. This is being researched and tested. Around 3800 test results are generated annually in the 11.000 m² test laboratory. They form a solid basis and support statements about suitability in different applications. This produces 30 to 50 new patents every year. Over 500 new blends are developed and tested every year. Only a handful of them come onto the market.

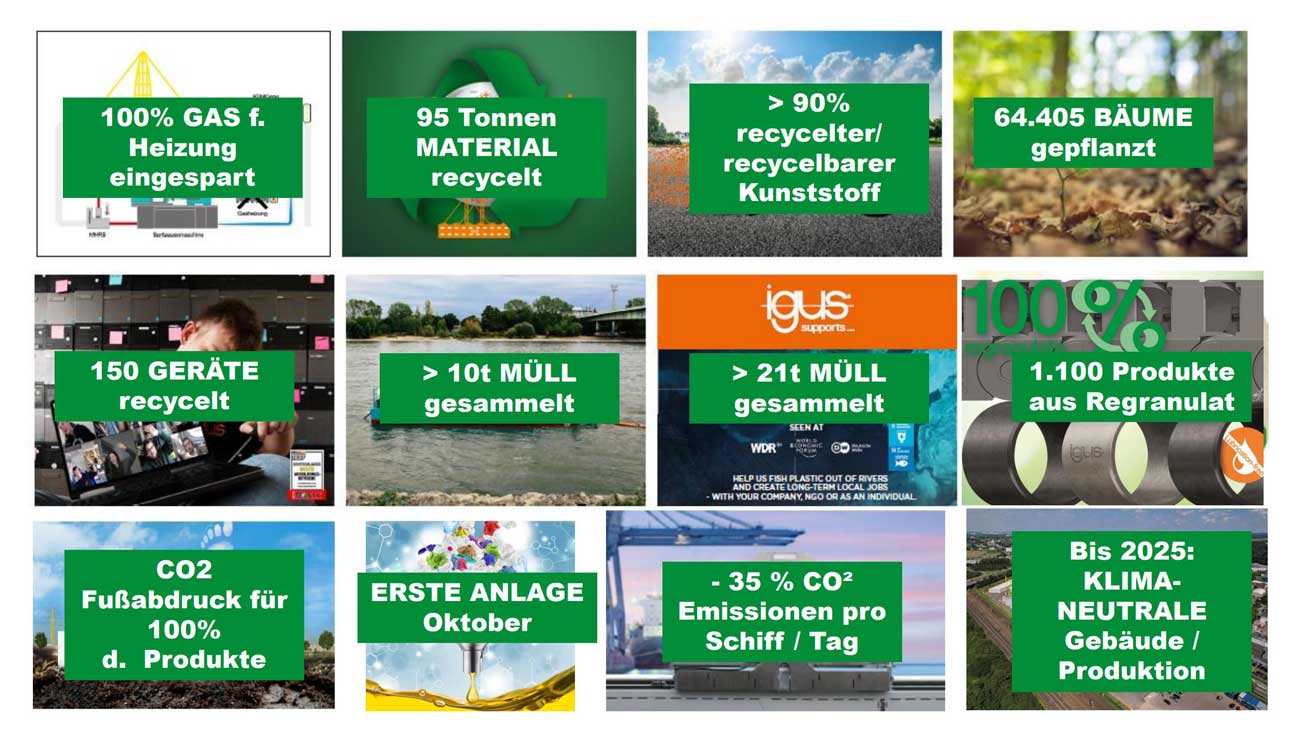

Clean Igus makes the plastic green

In addition to numerous environmentally improving investments in companies and organizations, managing director Frank Blase also wants to make investments himself sustained act: “Until 2025 we want with our buildings and production CO2 neutral be. We are on a good way." Mechanical recycling is an important step towards CO2 Neutrality. Igus has been granulating 50% of the plastic waste generated in its production for more than 99 years.

But there are many more ways to save energy, produce sustainable products and behave in an environmentally conscious manner. For better project planning and allocation of measures, the green topics have been divided into three areas:

But there are many more ways to save energy, produce sustainable products and behave in an environmentally conscious manner. For better project planning and allocation of measures, the green topics have been divided into three areas:

“This division makes it possible to look at questions in a more differentiated way and it becomes apparent where there are overlaps,” comments Lena Naumann, lean engineer and project manager. “And internally we can also better communicate our aspirations to our colleagues.”

With the program Clean Igus Numerous measures have been implemented in production: conveyor belts have been fixed to the machines and guide plates and magnetic foils have been used. This means that the parts are better steered and production rejects are avoided. The people of Cologne are currently involved with experts from around the world CO2 footprint to determine. Regardless of the outstanding results, the energy consumption of the injection molding machines is measured and reduced and investments are made in more energy-efficient machines. The machine occupancy is also subject to closer inspection.

Sustainable products from sustainable production

And so new products are constantly being created regranulate new ideas emerge to make production sustainable:

Curve slide made from recycled high-performance plastic

19.10.2023/XNUMX/XNUMX | The new Slide Drylin Econ from Igus are particularly sustainable. Iglidur ECO P regranulate is used for injection molding, which consists of 100% waste such as sprues and missing parts from injection molding production. You can realize movements in a quarter, half or full circle as well as convex and concave arch guides.

19.10.2023/XNUMX/XNUMX | The new Slide Drylin Econ from Igus are particularly sustainable. Iglidur ECO P regranulate is used for injection molding, which consists of 100% waste such as sprues and missing parts from injection molding production. You can realize movements in a quarter, half or full circle as well as convex and concave arch guides.

World's first urban bike made from recycled plastic

Oct 20.10.2023, XNUMX | Tomorrow's mobility from yesterday's waste: This is the vision we pursue igus:bike Concept, a bicycle that consists of over 90% plastic and is rust-free, grease-free and maintenance-free. The wheel can be made largely from recycled plastic waste such as old fishing nets.

Oct 20.10.2023, XNUMX | Tomorrow's mobility from yesterday's waste: This is the vision we pursue igus:bike Concept, a bicycle that consists of over 90% plastic and is rust-free, grease-free and maintenance-free. The wheel can be made largely from recycled plastic waste such as old fishing nets.

Plain bearing made of plastic regranulate

Oct 19.10.2023, XNUMX | Because plastic is a valuable resource and as little as a gram should be lost, Igus produces regranulate for the plain bearing series from sprues and missing parts from injection molding production Iglidur ECO. New to the range is the chemical-resistant version Iglidur ECO P210.

Oct 19.10.2023, XNUMX | Because plastic is a valuable resource and as little as a gram should be lost, Igus produces regranulate for the plain bearing series from sprues and missing parts from injection molding production Iglidur ECO. New to the range is the chemical-resistant version Iglidur ECO P210.

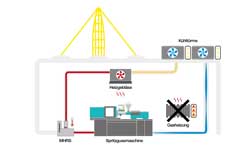

Hall heating concept uses waste heat from machines

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat with waste heat from machines and thus reduce gas costs and CO2 emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

May 15.05.2023, XNUMX | Igus engineers have a simple method heat recovery for the hall heating developed. They heat with waste heat from machines and thus reduce gas costs and CO2 emissions. The Cologne-based company also offers the concept of innovative technology to other companies – free of charge!

World's first 100 percent recycled e-chain

May 11.05.2022, XNUMX | From cradle to cradle: with the new one Cradle chain E2.1.CG Energy chain Igus once again conserves resources and extends the product life cycle. The world's first energy chain made from recycled material was developed based on Chainge's own energy chain recycling program.

May 11.05.2022, XNUMX | From cradle to cradle: with the new one Cradle chain E2.1.CG Energy chain Igus once again conserves resources and extends the product life cycle. The world's first energy chain made from recycled material was developed based on Chainge's own energy chain recycling program.

Projects, support and investments for sustainability

Igus not only wants to achieve its own CO2 neutrality, but also supports also promising environmental initiatives and start-ups. Find out more about your own projects and investments in other companies and organizations:

Recycling plastics for energy and drag chains

09.10.2023 | What happens when the maximum service life of a plastic energy or drag chain is reached? In most cases, it is simply disposed of and incinerated with other plastic waste. With the Igus green chainge recycling program Cologne is taking a completely new approach: users can send their plastic chains to Cologne for reprocessing - completely independent of the manufacturer.

In October 2022, the Chainge program was expanded into a platform and expanded to include six technical plastics. In addition to energy chains, other used plastics can now be registered for return quickly and easily. At the same time is a digital marketplace was created, which allows access to selected recyclates. In addition to taking back old energy chains, Igus has also been taking back old material as part of assembly orders since the beginning of the year.

igus invests in recycling technology from Mura

Oct 09.10.2023, XNUMX | Use instead of waste is the motto at Igus when it comes to plastic. That's why Igus invests in innovative plastic recycling technology MuraTechnology. With the Hydrothermal Plastic Recycling Solution (Hydro PRS), unsorted, non-classically recyclable plastic waste is converted back into crude oil using water, high temperature and pressure. Chemical recycling turns plastic waste into a valuable raw material within 25 minutes.

The Hydrothermal Plastic Recycling Solution Technology

With the Hydro PRS, a new, groundbreaking technology is now available that enables entry into a sustainable circular economy for plastic. The technology has the potential to all kinds of plastic zu recycle. It is estimated that every ton of plastic processed through advanced recycling saves 1,5 t of CO compared to incineration2.

To convert plastic waste into valuable chemicals and oil, Hydro PRS uses the Catalytic Hydrothermal Reactor Technology (Cat-HTR) from Licella Holdings Ltd. The method uses water, heat and pressure and is particularly interesting where mechanical recycling has been unsuccessful such as contaminated and mixed plastics.

Another important industrial company left KBR entered into a partnership with Mura in January 2021. KBR is active in more than 28.0000 countries with 80 employees. The company acts as a planner, plant manufacturer and operator of chemical factories and refineries.

Construction of the first large-scale facility is scheduled for April 2023 in Teesside, Great Britain, started. The first line, with a capacity of 20.000 tons per year, will be operational this year. By 2025 in Saxony Boehlen the first plant in Germany was also built.

With Dow A major partner has come on board that will not only provide financial support, but will also be the first buyer of recycled materials and supply major brands worldwide with sustainable plastic products. Once all planned lines are completed, Mura will be able to deliver up to 80.000 tons to recycle plastic waste per year.

Green electricity from historic windmills

Oct 09.10.2023, XNUMX | The students of the HTWG University of Konstanz – In their Sailwind 4 project, technology, business and design rely on small windmills to generate green electricity. They want to recreate a Greek sailing windmill, one of the oldest known devices for using wind energy, which is now a cultural asset in the Mediterranean region from Turkey to France.

Oct 09.10.2023, XNUMX | The students of the HTWG University of Konstanz – In their Sailwind 4 project, technology, business and design rely on small windmills to generate green electricity. They want to recreate a Greek sailing windmill, one of the oldest known devices for using wind energy, which is now a cultural asset in the Mediterranean region from Turkey to France.

In the past, these mills were mainly used for grinding grains and legumes. In the future, they will use a generator to generate green electricity. Thousands of mills already exist and can be used as Mini power plants can be retrofitted for green electricity – a big advantage.

“Igus is known for being committed to innovative projects by schoolchildren and students,” says Professor Dieter Schwechten, who initiated Sailwind 4 together with Professor Ditmar Ihlenburg. “We are very pleased to have won the company as our first partner and hope to be able to gain additional industry supporters for the project.”

Lubrication-free components reduce maintenance costs

The students would like to start building the first windmill in October. Visually, it will retain the typical characteristics of the historical model: cylindrical tower and tapered roof construction. This also applies to the wing rods located on the rotating main shaft.

The engineers want to work on them, however High-tech sails attach and connect the shaft to a power generator. At wind force 14, the prototype windmill with a 4 m rotor diameter should generate 5 kWp of electricity. The small wind system could also be combined with a photovoltaic system and battery storage. “We have set ourselves the mechatronic task of completely automating the operation of the sailing windmill, like with large wind turbines,” explains Schwechten. “After all, there are no millers left to operate windmills today.”

Igus provides the following robust, fail-safe, corrosion-free, lubrication-free and maintenance-free components for this automation free of charge:

- linear guides for motorized trimming of the sails

- Slewing ring bearing for the rotor

- Find numerous bearings made of high-performance plastic.

Rhine octopus fishes plastic from the river

09.10.2023/XNUMX/XNUMX | That bank of the Rhine is a popular meeting place that attracts numerous Cologne residents and visitors every day and, unfortunately, also a huge amount of plastic waste. According to researchers, around 10 tons of plastic end up in the Rhine every year. This makes it one of the most plastic-contaminated bodies of water in the world.

09.10.2023/XNUMX/XNUMX | That bank of the Rhine is a popular meeting place that attracts numerous Cologne residents and visitors every day and, unfortunately, also a huge amount of plastic waste. According to researchers, around 10 tons of plastic end up in the Rhine every year. This makes it one of the most plastic-contaminated bodies of water in the world.

The rubbish from Cologne continues to float into the North Sea and ultimately ends up in the world's oceans. Estimated 380 tons of plastic The Rhine washes into the North Sea every year, at the bottom of which, according to estimates, over 600.000 m3 Waste, mostly plastic waste, lies. By the way, more than 1000 rivers wash the majority of the world's plastic waste from the land into the seas.

Because the Cologne industrial company also aims to advance the circular economy for plastics, Igus supports local projects like this Rhine octopus, which intercept plastic waste before it reaches the oceans. The Rhine octopus has been resident on the left bank of the Rhine north of the Cologne Zoo Bridge since 2022.

The floating garbage trap Cologne Rhine Cleanup Command Unit (KRAKE eV) fishes waste out of the Rhine around the clock. The collecting basket, which is opened against the direction of flow, is attached between two floating bodies. It captures plastic floating on the surface of the water without posing a danger to fish and birds. The Kraglings, club members, regularly empty the garbage trap and sort the material. Scientific studies are then carried out and recommendations for policy are developed.

Collecting plastic waste in Indian rivers

March 18.03.2023, XNUMX | Collecting plastic waste from rivers before it can reach the oceans is also the approach Plastic fishermen. According to their own information, this is up to 300 times cheaper than fishing plastic out of the sea. Igus supports the river cleaning initiative by funding the collection of a total of 10.000 kg of plastic waste from Cologne.

March 18.03.2023, XNUMX | Collecting plastic waste from rivers before it can reach the oceans is also the approach Plastic fishermen. According to their own information, this is up to 300 times cheaper than fishing plastic out of the sea. Igus supports the river cleaning initiative by funding the collection of a total of 10.000 kg of plastic waste from Cologne.

In January 2023 there were already 3340 kg collected and processed in Kanpur and Mangaluru (India). Comparatively, this corresponds to more than 150.000 plastic bags. The financial support provided 34 people with a regular income. On some days, helpers came along.

Since the start, Plastic Fischer has collected over 520 tons of plastic waste in both countries. A project in Vietnam is planned next. Empower AS verifies the collection to ensure accuracy.

How does the trash boom work?

The garbage collection works as follows: The ones developed by Plastic Fischer Trash booms are built on site using locally available materials. The modular system consists of a robust steel frame, tubes as floats and galvanized grids to stop plastic waste.

The resulting floating barrier is anchored in the river, launched and emptied daily. The concept haunts you Triple L approach: locally developed (local), technically simple (low-tech) and inexpensive (low-cost). This solution saves carbon, time and money compared to high-tech imports, can be repaired quickly and is scalable.

Trainees bring old electrical devices to life

April 28.04.2022, XNUMX | The motion plastics specialist trainees have their own company called Regus founded. be here discarded electronic devices prepared and offered for sale in our own webshop. The proceeds go to sustainable projects.

April 28.04.2022, XNUMX | The motion plastics specialist trainees have their own company called Regus founded. be here discarded electronic devices prepared and offered for sale in our own webshop. The proceeds go to sustainable projects.

FAQ

What are sustainable plastics?

Sustainable plastics are polymers that are either made from renewable resources, can be degraded in an environmentally friendly manner or can be recycled particularly efficiently. You should ecological footprint and reduce the consumption of fossil resources.

Can plastic be sustainable?

Ja, Plastic can be sustainable if it comes from renewable sources, is efficiently recyclable or biodegradable, thus minimizing the environmental footprint.

Which plastics are environmentally friendly?

Environmentally friendly plastics are those that are biodegradable, made from renewable resources or can be efficiently recycled. Examples include polylactic acid (PLA), polyhydroxyalkanoates (PHA) and some organic polyethylene.

Can you recycle plastic 100%?

No, currently plastic cannot be 100% recycled. While many plastics are recyclable, contamination, mixtures of different types of plastic and technical limitations mean that not all plastic waste is fully recycled. Some plastics can also only be recycled a limited number of times because their quality decreases with each recycling cycle.

What types of plastic recycling are there?

The choice of recycling method depends on the type of plastic and the desired end product. There are these ways to recycle plastics:

- mechanical Recycling: Crushing and melting plastic waste to make new products.

- Chemical Recycling: Breaking down plastics into monomers or basic chemicals that are used for new production.

- Thermal Recycling: burning plastics to generate energy.

- Biological Degradation: Use of microorganisms that can break down certain plastics.

- Upcycling: Plastic waste is converted into higher value products.

You might also be interested in...

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.

linear guide | Precise, light, durable

Fit calculator | Tools for fits and tolerances

The author Oliver Cyrus is Head of Press + Advertising at igus GmbH in Cologne.