Linear rail + linear axis also for heavy loads

- Details

- Hits: 8178

Rollon has always focused on the requirements of its customers with the aim of offering them high added value and maximum efficiency. Now the Düsseldorf specialist for Linear Technology into a new era with three product families of the linear guide and Linear axis. Rollon is for heavy loads and high cycle numbers Induction hardening the linear rail is the first choice. Further information can be found below:

Contents

- Induction hardening for highly cyclical heavy-duty applications

- Fast linear rail covers tens of thousands of kilometers maintenance-free

- Linear rails for heavy loads and high cycle numbers

Induction hardening for highly cyclical heavy-duty applications

November 19.11.2020, XNUMX | Rollon sets for Linear guides for heavy loads and high number of cycles induction hardened linear rails. This enables resilience, wear resistance and resistance to deformation to be implemented. The specialist for linear motion systems has perfected the demanding process over decades. As a result, the linear guides with induction-hardened raceways meet the highest demands in terms of quality, durability and reliability.

These features are required in warehouse automation, in Robotcells, machine tools or rail vehicles. To get in Industrial automation and active in Heavy-duty applications In order to meet the required robustness, longevity, dynamics and performance, a high degree of hardness of the designs is crucial.

Chuck innovations for efficient metal processing

Chuck innovations for efficient metal processing

Because the less hardened the surface of the raceways, the more susceptible they are to damage. In addition, too few have an effect Hardness depths negatively affect the load capacity. Linear rails with thin hardened outer layers tend to crack quickly under load. This is related to the position of the maximum stress (Hertzian pressure) between the roller or ball and rail. Because this is located below the surface, at a depth that many hardening processes cannot achieve.

In the Induction hardening The heat treatment enables great depths of hardness and penetration into the areas of maximum stress. As a result, users get a particularly hard and wear-resistant Surface. Induction-hardened linear guides achieve high performance without damaging or deforming the raceways of the linear guide.

On the one hand, Rollon is a specialist in this inductive hardening of careers with extensive specialist knowledge and, on the other hand, has years of experience. During induction hardening, the area of the steel to be hardened is first heated inductively using an electromagnetic field and then quenched.

Wear-free spindle nut made of plastic for heavy loads

Wear-free spindle nut made of plastic for heavy loads

This transforms the structure martensitically and experiences a significant increase in hardness. For maximum degrees of hardness Rollon only uses high quality Steels with a high carbon content. The surface can be processed immediately after induction hardening. The surface quality and thus the friction properties are improved by grinding or honing.

Reach the Rollon linear rails Rockwell hardening between 58 and 62 HRC and hardness depths of around 1,2 mm. The induction-hardened and ground raceways are heavy-duty, low-maintenance and extremely durable. O they allow significant performance increases in industrial and heavy-duty applications.

Fast linear rail covers tens of thousands of kilometers maintenance-free

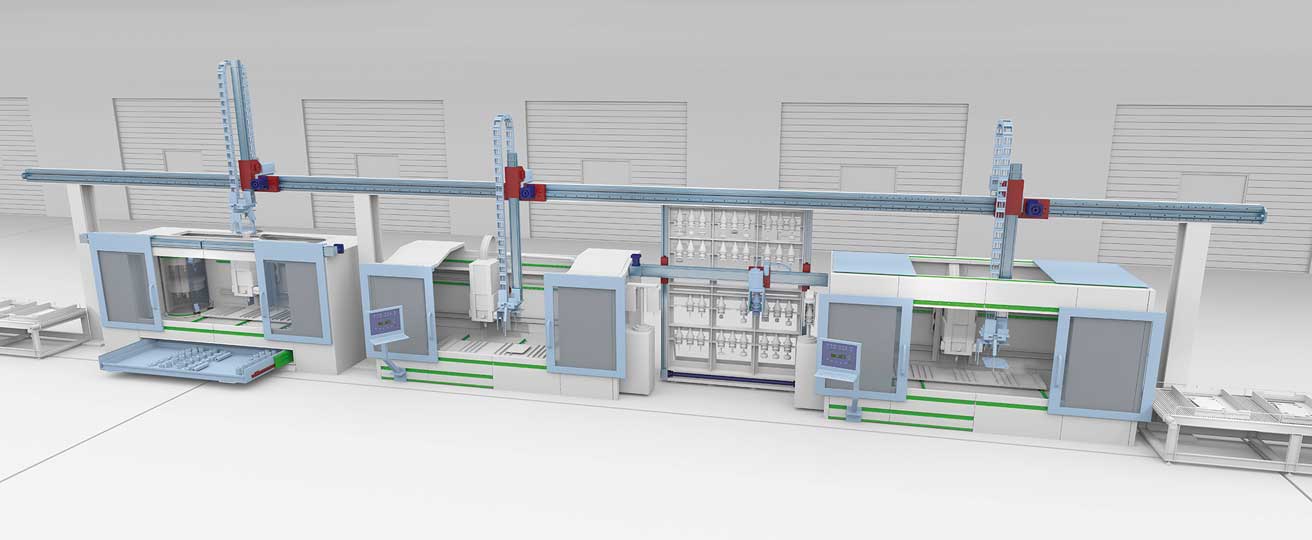

27.10.2020/XNUMX/XNUMX | the Linear rail Speedy Rail from Rollon is a self-supporting and self-aligning linear guide made of extruded aluminum. It is very dynamic, robust and reliable. This makes the modular guide rail suitable for automation in machine and plant construction.

Applications can be found in automobile assembly as well as in welding systems, woodworking machines or packaging technology. Here, high speeds, accelerations and a high load capacity are often required at the same time. The working environment is demanding.

Such applications are just right for the modular rails Speedy Rail Model series. The modular linear rails are extremely dynamic, offer high wear resistance and are very resilient. The linear aluminum rail runs extremely reliably and quietly even in dirty, damp, abrasive or corrosive environments.

The Speedy Rail tracks can cover up to 80.000 km without maintenance. The rails have to too not lubricated become. They have a special structure with hollow cross sections. The aluminum alloy has a hardened, anodized surface. This means that the linear guides can absorb high bending forces and torsional forces.

Calculate deflection from profile rails and linear axes

Calculate deflection from profile rails and linear axes

This makes the Speedy Rail linear rail very stable and shines with minimal deflection. Gantry constructions can be used with Load ratings of up to 3 t being constructed. The runners have dust-protected, plastic-coated steel rollers. Arranged in a V-shape or cylindrical shape, they are resistant to contamination and pollutants.

The linear guides reach speeds of up to 15 m / s with accelerations of up to 10 m / s2. Up to 7500 mm length can be realized in one piece. If necessary, several rail segments can be connected to one another. There are no limits to the total length of the traverse paths. The individual linear rail segments are connected using dovetail clamps.

Linear guide or linear axis - both possible

The Speedy Rail linear rail can be used as a linear guide or with a belt drive or rack and pinion drive as a linear axis. The high dynamics and load capacity predestine the guide rail for the construction of 2- or 3-axis Cartesian systems.

They come in Welding systems, Sheet metal cutting systems, presses or punching machines are used. Also machines for woodworking, painting and Ceramic processing as well as marble boring mills and Automotive Applications can be automated very easily with the modular linear rails.

Linear rails for heavy loads and high cycle numbers

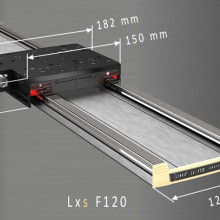

20.06.2020/XNUMX/XNUMX | The design and technological redesign affects the linear guide series Compact Rail and the linear axis of the series More and Smart. With the Compact Rail Plus, Rollon is also launching a completely new linear guide for heavy loads. This combines the excellent running properties of the Compact Rail with an extremely high load capacity.

Plastic-linear bearings as a better alternative

Plastic-linear bearings as a better alternative

The new Rollon products unite Performance, efficiency and Design at the highest level. They help users to simplify their system designs, increase performance and reduce costs within a short period of time.

Steel compact rail linear guide

The Compact Rail is a steel linear guide with induction-hardened, ground raceways and a newly designed, robust steel runner. The self-aligning linear guides are compact and insensitive to dirt and dust. The guides deliver high travel speeds up to a maximum of 9 m / s and accelerations up to a maximum of 20 m / s2.

In addition, they have Roller guides have a long service life, require little maintenance and cause only quiet movements. The tolerance compensation of the new linear guides is characteristic. Combinations of different guide rails and bearings perfectly compensate for parallelism errors on the mounting surface in one or two planes.

Compact Rail Plus linear guide

The Compact-Rail Plus offers a new solution for applications in which high dynamics, insensitivity to contamination, smooth running, fixed / loose bearing compensation and high load ratings are required.

Reading tip: rollingWarehouse for everyone in over 60 industries

Reading tip: rollingWarehouse for everyone in over 60 industries

The linear guides have a unique rail concept with convex raceway and double row Ball bearings. In combination with Rollon know-how for the hardening and grinding process, significantly higher load ratings can be implemented with radial 65% and axial 170%. This makes the Compact Rail Plus linear guide an economical alternative to profile rail guides.

Flexible plus and smart linear axis

In the actuators were that Plus system ELM and Robot as well as that Smart system E-Smart and R-Smart have been redesigned. The drive heads have been standardized to the tried and tested solution for the smart axes. This gives users maximum flexibility when it comes to connecting the gearbox.

The number of variants has been reduced. This has a positive effect on delivery times and spare parts inventory. The plus system includes specially protected linear axes for the Use in polluted surroundings. The smart system is particularly simple, but extremely effective. This makes it particularly suitable for demanding applications in Automation lines the industry.

The new items are available now. E-mail address: info@rollon.de The expansion of the technological and aesthetic redesign to the entire portfolio will follow gradually.

You might also be interested in...

Cobot | Discover collaborative robots as a new employee

Rollon | The engineering partner

Linear axis | Precision and drive diversity

Linear axis portals load water jet cutting system

Telescopic rails for the stable trunk full extension

Linear unit | With spindle guide and ball screw drive

Klaus Hermes is Marketing Manager at Rollon GmbH in Düsseldorf.