Scara robots - off to the digital transformation

- Details

- Hits: 2949

The SCARA robot from Mitsubishi Electric are suitable for a wide range of applications including assembly of small parts, heavy payloads, and handling and packaging applications. With his extraordinary motor and amplifiersystem, the robots work with high precision at high speeds. Discover the new and further developments of the Scaras:

Contents

- Scara robots for beginners in digital transformation

- Force Sensor for control in articulated arm and Scara robots

- What is a Scara robot?

Scara robots for beginners in digital transformation

23.06.2022/XNUMX/XNUMX | The new Melfa RH-CR Scara robot from Mitsubishi Electric offer a space-saving solution for those new to the Robotic. User-friendliness and cost-efficiency were the focus right from the design stage. The new industrial robots are particularly suitable for companies that are just starting out Automation and digital transformation start.

For an easy introduction to the Industrial robots Automation and the associated increases in efficiency, Mitsubishi Electric has the RH-CR series developed. The new Scara robots are easy to operate and commission. In addition, they are around 20% cheaper than comparable Scara robotics.

4 axes for pick-and-place applications

With four axes and 700mm range the RH-CR Scara robots are very well suited for pick and place applications, assembly, handling as well as sorting and palletizing movements. So far, the robot's areas of application have ranged from plant handling in agriculture to games console production in the Electronicsto find industry. The load capacity of the Scara robot is 3 or 6 kg and the cycle times are up to 0,41 s with an accuracy of ± 10 µm. The new Scara robots thus offer the best performance for the compact weight class.

Cobots as a door opener to the establishment of robotics in factory automation

Cobots as a door opener to the establishment of robotics in factory automation

The Scara robots only require around 65% of the floor space of a conventional robot. In addition, based on the Melfa Safeplus function, it is possible to work collaboratively with people dispensed with bulky fencing .

Scara robots for users with little experience

For companies that don't yet have a large robot Experiences have, ease of use and setup are important. This Scara robot offers a good starting position for this. Users can subsequently build on the knowledge and initial experience.

For companies that don't yet have a large robot Experiences have, ease of use and setup are important. This Scara robot offers a good starting position for this. Users can subsequently build on the knowledge and initial experience.

Mitsubishi Electric offers an extensive starter set for the Scara robot RH-CR series. This contains the intuitive software for Coding RT Toolbos3, a compact CR800 robot controller and one R56TB robot teaching box. Customers also have access to extensive online tutorials. Here you can learn the necessary basics quickly and easily.

All elements in the RH-CR robot starter set are easy to use and do not require any specialized programming knowledge. With the CR800 robot controller and RT Toolbox3 software, users can also operate all other robot series from Mitsubishi Electric. This significantly simplifies the implementation of more complex applications afterwards. Because the RH-CR Scara robot integrate into different networks can also communicate with other robots and devices. In this way, companies invest in sustainable systems and in the skills of their employees. This point is particularly important to Mitsubishi Electric.

Grow as part of the digital transformation

“With our automation solutions, we want to support companies and their employees in the context of the digital transformation to grow,” summarizes Michael Finke together. "The new Scara robots are an important link for us in bringing humans and robots together and thus enabling the intelligent production systems of the future."

Industrial robots for handling, assembly and Industry 4.0

Industrial robots for handling, assembly and Industry 4.0

The Melfa RH-CR Scara robots belong to Efficiency line up Mitsubishi Electric program. With the usual high quality, this series offers cost-optimized product lines with less performance and functionalities. This also includes the MR-JET Servos and the frequency converter of the FR-CS80 series.

Mitsubishi Electric is exhibiting at AMB 2022.

Force Sensor for control in articulated arm and Scara robots

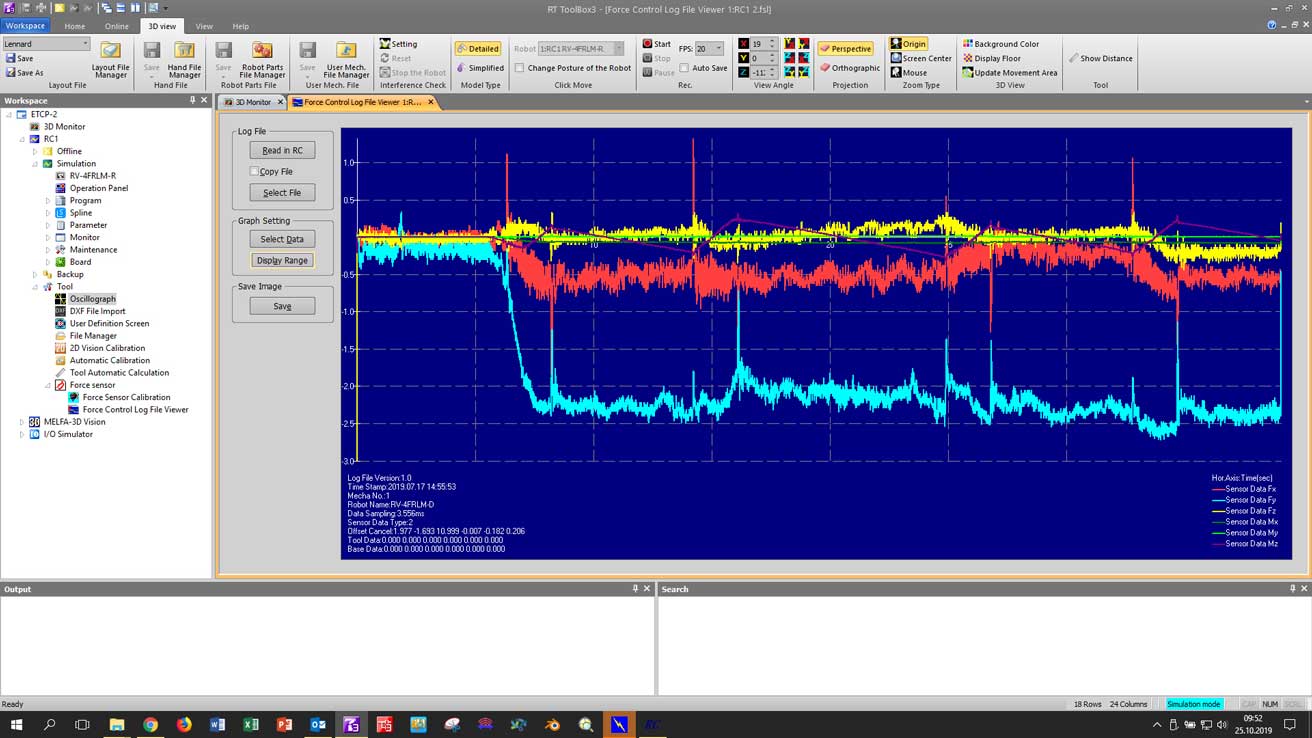

30.10.2019/XNUMX/XNUMX | The new Melfa articulated arm robots and Scara robots Series RV-FR and RH-FR from Mitsubishi Electric are now supported by a force-torque sensor that can be integrated directly into the CR750/751 and CR800 robot controllers. Because the force sensor does not have its own controller, the processes are significantly simplified and engineering costs are saved.

The Force sensor regulates the force with which a robot interacts with its environment based on preset values. The functionalities of the force-torque sensor are divided into three areas: The Melfa Sense control includes the feedback-based control of the robot, the Melfa Sense detection registers limit and reference points and the Melfa Sense Logging logs, transmits and processes the recorded force sensor information.

Graphic HMI operator terminals for industrial automation

Graphic HMI operator terminals for industrial automation

In applications like joining and assembling the pressure intended for handling the respective object can be readjusted via the feedback of the force sensor. Since the position and force data are stored in real time, the program's control parameters can be used to intelligently teach the robot.

The real-time control loop allows the precise, constant exertion of force, so that e.g. For example, delicate deburring and polishing work on sensitive plastic parts can be automated with the robot. With the help of the Force Sensor, the robot reacts to or recognizes the surface properties of objects to be processed based on the resilience or the damping coefficient. It is therefore suitable in certain applications as an alternative to the vision system.

The real-time control loop allows the precise, constant exertion of force, so that e.g. For example, delicate deburring and polishing work on sensitive plastic parts can be automated with the robot. With the help of the Force Sensor, the robot reacts to or recognizes the surface properties of objects to be processed based on the resilience or the damping coefficient. It is therefore suitable in certain applications as an alternative to the vision system.

The logging of force sensor information enables valuable data assets to be built up via the programming software RT Toolbox can be sent to an FTP server for further analysis. This data is used for quality assurance in haptic tests, for example on the correct response behavior of pushbuttons and rotary controls in the automotive industry. The traceability of the robot test over several years also speeds up troubleshooting on the production lines.

The innovative Force Sensor is now available for the entire range of robots from Mitsubishi Electric and their controls.

What is a Scara robot?

A Scara robot is an industrial robot typically used for assembly or pick-and-place tasks. Scara stands for "Selective Compliance Assembly Robot Arm". Here are some key features of Scara robots:

- Capability: Able to work quickly and accurately, Scara robots can perform a wide range of tasks.

- Precision: Scara robots have high positioning accuracy and repeatability.

- Restricted Movement: Unlike articulated robots, Scara robots have a limited range of movement, which means they are not as flexible as other types of industrial robots.

- Areas of application: Scara robots are often used in the electronics industry, the automotive industry and in laboratories.

Safety brake protects Robco robot kit

Safety brake protects Robco robot kit

Although Scara robots are not as flexible as other types of industrial robots, they still offer a powerful solution for specific applications. If you are looking for a robot for assembly or pick and place tasks, a Scara robot can be a good choice.

You might also be interested in...

Artificial Intelligence | trends and developments

Mitsubishi Electric | Automating the World

Intelligent CNC control for machine tools

battery production | Facts and Technologies

Industrial Ethernet | Profinet, Powerlink & Co.