battery production | Facts and Technologies

- Details

- Hits: 6559

Efficient vehicle batteries for the Electromobility are manufactured in highly automated processes. As the use of data make production more efficient, white Mitsubishi Electric. For the efficient control of the machines and systems in the battery production also ensure many sensors of Pepperl + Fuchswho work with different measuring methods. There are many to handle Vacuum gripper technology from J. Schmalz.

Contents

- Future battery production for e-cars in Germany and the EU

- Technologies for battery production for electric cars

- Magnetic gripper for the production of round cells

- Risky tests on lithium ion batteries

- Data utility for lithium-ion battery productionn – video cast

- Special grippers and end effectors for battery production

- Sensors for the relevant process steps in battery production

- Production of e-car ion batteries in Europe

- FAQ

Future battery production for e-cars in Germany and the EU

In Europe arises in the coming years the world's largest battery market. Germany will become one of the leading battery producers. From the 900 GWh battery capacity required for electric cars by 2030, the storage capacities in Europe will increase to 1300 GHh according to the RWTH Aachen University. Germany will cover over 478 GWh of this by the end of the decade. Of this, 200 GWh will come from Tesla in Grünheide, 100 GWh from CATL in Erfurt and 24 GWh each from VW and Northvolt from Salzgitter and ACC in Kaiserslautern. This capacity is sufficient for approx. 26 million battery-powered cars with an energy content of 50 kWh or 13 million Audi A6 E-Trons with 100 kWh.

Frequency converter: decentralized, networked with app and much more.

Frequency converter: decentralized, networked with app and much more.

Since 2009, the federal government has been funding the Electromobility and also drives the development and production of battery technology. Business and politics are working to build up the know-how for battery production. Dr. Michael Meister, Parliamentary State Secretary to the Federal Minister of Education and Research, confirmed at the Battery Forum Germany 2021 that economical battery cell production is possible in Germany.

Automobile manufacturers report collaborations, research laboratories and test operations for series production confirm this. In addition to use in... E-mobility Batteries are also important for everyday life. But stationary use is also relevant, for example to buffer energy generated from renewable sources.

Mitsubishi Electric and Novali as partners in large-scale production

18.07.2022 | Mitsubishi Electric Europe and the Belgian start-up Novali have joined forces to advance large-scale production of battery cells in Europe. "This strategic partnership aims to reduce Europe's dependence on external battery sources and strengthen manufacturing capabilities within the EU trading bloc," says Roald De Meyer, co-founder of Novali.

18.07.2022 | Mitsubishi Electric Europe and the Belgian start-up Novali have joined forces to advance large-scale production of battery cells in Europe. "This strategic partnership aims to reduce Europe's dependence on external battery sources and strengthen manufacturing capabilities within the EU trading bloc," says Roald De Meyer, co-founder of Novali.

With Mitsubishi Electric's expertise in automation solutions and Novali's agile dynamics, scaling the production of next-generation battery cells will be realized. The project not only supports the European electrification initiative, but also contributes to sustainable manufacturing with the aim of: CO2-neutrale battery production to be achieved. This cooperation will create a strong network of local machine builders that will strengthen the supply chain and ensure the availability of batteries in large quantities.

Novali was founded by several Giga factories to finance and supply throughout Europe. Production is expected to start in 2025. To meet this deadline, Novali has entered into a technology partnership with Mitsubishi Electric Europe.

"Mitsubishi Electric has decades of experience in supplying automation technology to all established cell and equipment manufacturers in Asia. The aim of this alliance is to use this know-how to build a local ecosystem of European manufacturers," said Roald De Meyer .

Siemens opens robotic battery module factory in Norway

29.01.2019/XNUMX/XNUMX | Siemens today opened one of the world's most advanced and robot-supported battery module factories together with the Norwegian Prime Minister Erna Solberg in Trondheim/Norway. In the future, here will be daily 55 battery modules per shift assembled for the marine and offshore market. "We expect this market to grow significantly in the future. For this reason we have invested heavily in the development of safe and reliable battery solutions," says Bjorn Einar Brath, Head of Offshore Solutions at Siemens.

Reading tip: Measurement technology for hydrogen production

Reading tip: Measurement technology for hydrogen production

The factory includes a robotized and digitized production line with eight robotic stations with one Capacity of up to 300 MWh per year. From unpacking the incoming production parts to checking the finished battery module, assembly is fully automated. A battery consists of nine battery modules, with each module being made up of 28 battery cells.

Technologies for battery production

Powerful vehicle batteries for electromobility are manufactured in highly automated processes. The manufacturers need a lot for this Automation services, which we present to you below:

Magnetic gripper for the production of round cells

11.12.2023/XNUMX/XNUMX | The grasping of round cells in electric vehicle production is very demanding. This is because the round cells have to be brought together closely during the manufacturing process. The specially developed design of the HM1046 from Room, Combined with a holding force of 50 N, the round cells hold securely even at high accelerations and emergency stop situations.

11.12.2023/XNUMX/XNUMX | The grasping of round cells in electric vehicle production is very demanding. This is because the round cells have to be brought together closely during the manufacturing process. The specially developed design of the HM1046 from Room, Combined with a holding force of 50 N, the round cells hold securely even at high accelerations and emergency stop situations.

Risky tests on lithium ion batteries

November 08.11.2023, XNUMX | The beta test phase for a new test chamber is currently underway White technique: The “Extreme Event” is the first to have tertiary explosion protection, which limits the effects of explosive fires during destructive tests on lithium-ion batteries to a safe level.

The very powerful Li-ion batteries for electric vehicles can catch fire and explode. At Stress testing, the so-called destructive tests, the developers deliberately bring about such extreme situations in order to gain knowledge about the functionality and safety of the energy storage devices. This requires an appropriate test environment.

Special Atex test chamber for electric car batteries

Weiss Technik has equipped a new test cabinet with tertiary explosion protection for electrical, mechanical or thermal overload tests on lithium-ion batteries. The protection of the Extreme event ranges from the explosion-proof construction to the pressure relief mechanism. The cabinet is also suitable for testing electronic components in the high-voltage range or Hydrogencomponents.

Explosion protection is regulated by the Atex-Standard 2014/34/EU. The 99/92/EC standard applies to system operators. This includes the division of the hazard areas within the facility into zones - measured by the probability of the entry of an explosive atmosphere: low (Zone 2), occasional (Zone 1) or high (Zone 0).

The risk classes for battery damage issued by the European Council for Automotive Research & Development (Eucar) range from 0 to 7 and include, for example: B. a reversible loss of function at level 1, fire or flame at level 5 and finally the explosion at the highest Hazard level 7. The new test room with tertiary explosion protection is designed for tests with increased events from hazard levels 5 to 7.

For thermal tests The Extreme Event can be expanded to include an air conditioning device and is easy to control using the S!MPATI software from Weiss Technik.

Data utility for lithium-ion battery production

July 26.07.2023, XNUMX | The market for more sustainable solutions in electromobility continues to grow. The demand for Li-ion batteries (LIBs) is increasing rapidly. The rule here is: the early bird catches the worm, or rather the cargo. Who promptly qualitatively large quantities of high-quality batteries that can be recycled, sustainably and cost-effectively is at the forefront.

July 26.07.2023, XNUMX | The market for more sustainable solutions in electromobility continues to grow. The demand for Li-ion batteries (LIBs) is increasing rapidly. The rule here is: the early bird catches the worm, or rather the cargo. Who promptly qualitatively large quantities of high-quality batteries that can be recycled, sustainably and cost-effectively is at the forefront.

Explained in the "Lithium Ion Batteries" videocast Claus Petersen, Director - Automotive & Lithium Battery Industries, Factory Automation EMEA Mitsubishi Electric Europe BV on how digital technologies can help the LIB industry to generate a competitive advantage with data.

These are exciting times for the manufacturers of LIB cells, because they are the products of the present and the future. Therefore, battery cell production requires optimization and expansion of the supply chain.

E-mobility is one of the big topics in the battery industry because Decarbonization of the transport sector innovations and sustainable solutions are in demand. In order to deliver LIB cells with optimal capacity, voltage and durability for individual requirements, while minimizing waste, energy consumption and resource use, companies need to understand their customers' needs.

Data control for optimized process control

The magic word is: data control. Process control can be designed effectively and future-proof using data. Thanks to his extensive experience as a quality specialist in the automotive industry, Klaus Petersen knows exactly how process knowledge can help to improve end products and production efficiency. In order to make optimal use of these advantages, the manufacturers of LIB cells must continuously monitor their production. This is the only way to draw conclusions about quality and quantity. For example, inefficiencies could be identified and eliminated, and production costs reduced. Competitive LIB cells would be the result.

Share technology knowledge about electric car batteries

This focused overview of processes and products illustrates the need for automation. With Automation services parameters can be adjusted in real time and the productivity of quality batteries can be improved. In addition, fully integrated production lines can be set up, which can also be connected to partner companies for data exchange. Valuable knowledge could be shared, traceability supported and quality-driven supply chains created with a limited environmental footprint.

Video cast with Klaus Petersen

Special grippers and end effectors for battery production

June 16.06.2022, XNUMX | Foils made of copper and aluminum have to withstand a lot in battery production before they fulfill their role as anode and cathode can detect in a battery. The handling between the individual production steps has to be all the gentler, but how can this be achieved? The greatest care and precision must be reconciled with competitive battery cell production. J. Schmalz offers special grippers and end effectors as little helpers for the gentle transport of sensitive cathodes, anodes, separators and pouch cells.

From powder to pouch in battery production

Two metal foils and two pastes form the Basis of a traction battery. For the anode, a graphite mass is spread on a copper foil. The cathode consists of an aluminum foil to which a metal oxide mixture of cobalt, nickel, manganese and lithium is applied. After the foils, which are coated on both sides, have been dried, calendered and cut to size, they are ready for stacking.

Two metal foils and two pastes form the Basis of a traction battery. For the anode, a graphite mass is spread on a copper foil. The cathode consists of an aluminum foil to which a metal oxide mixture of cobalt, nickel, manganese and lithium is applied. After the foils, which are coated on both sides, have been dried, calendered and cut to size, they are ready for stacking.

"We recommend the special grippers STGG for this, as they can handle the sensitive foils in a highly dynamic manner," explains dr Mike Fiedler, Head of the Vacuum Automation and Vacuum Handling divisions. The STGG alternately grabs the anode, separator, cathode and separator again to place them on top of each other. The focus is just as much on speed as on precise positioning. The gripper must not leave any marks and must not contaminate the sensitive coating.

“Our solution is called Peek“says Dr. Fiddler. A suction plate with many small holes that grips the entire surface is made from the chemically highly resistant polyetheretherketone. The flat surface minimizes the surface pressure, while the active blow-off function of the STGG accelerates the pick-and-place process.

The high volume flow prevents particle residues on the electrodes. The pneumatic vacuum generation without moving parts qualifies the special gripper for clean rooms and dry rooms. The STGG is also suitable for separating and depositing thin separator films. Separators usually consist of very fine-pored, flexible fleeces or plastics. They spatially separate the cathode and anode from each other and prevent a short circuit. They are also permeable to the positive Li-ions.

These flow from the anode to the cathode when discharging and travel back again when charging. “The STGG works with a high volume flow and therefore also grips porous materials securely,” explains Dr. Fiddler. The ESD-compliant surface reliably dissipates electrostatic charges and protects against unwanted ones adhesion.

Cell by cell to the battery

When the cell stack is finished, the protruding conductor tabs are shortened and the stack is split into one pouch film packed. Sealed all around, the pouch cell is ready for electrolyte injection. “The pouch cells are sensitive and must not be deformed by the gripper under any circumstances. They can also vary in shape depending on the application," explains Dr. Fiddler.

gripper | pneumatic + electric from various manufacturers

gripper | pneumatic + electric from various manufacturers

The Lightweight gripper SLG adapts to any geometry. After the user has configured this online, it is additively manufactured. Structured SFF or SFB1 suction cups prevent the aluminum composite foil of the pouch cell from being deep-drawn when gripping. Both combine support surfaces in the form of honeycombs on the suction surface with a particularly flat and soft sealing lip. They grip gently with a high suction force without deforming the surface of the pouch cell.

How and where the vacuum is generated is important for highly dynamic and safe handling. “Our decentralized vacuum generators SCPM series meet all requirements. They are compact and powerful at the same time,” says Dr. Fiddler. Due to their size, they can be mounted close to the suction pad, thus minimizing power losses. The valve of the compact vacuum ejector closes when there is no power. The gripper thus holds the battery cell securely, even in the event of a power failure. "Another advantage is that users can integrate special functions into the system, such as redundant vacuum generation or workpiece recognition," adds Dr. Fiddler.

How and where the vacuum is generated is important for highly dynamic and safe handling. “Our decentralized vacuum generators SCPM series meet all requirements. They are compact and powerful at the same time,” says Dr. Fiddler. Due to their size, they can be mounted close to the suction pad, thus minimizing power losses. The valve of the compact vacuum ejector closes when there is no power. The gripper thus holds the battery cell securely, even in the event of a power failure. "Another advantage is that users can integrate special functions into the system, such as redundant vacuum generation or workpiece recognition," adds Dr. Fiddler.

In a module, the cells are connected in series or in parallel. Several modules make one battery Pack. Depending on the vehicle category and manufacturer, it combines fewer or more pouch cells.

Round cells instead of flat pouch cells

The versatile pouch cells are flat and give off heat well. They make optimal use of the available volume in a battery module. However, their shell is sensitive and does not protect anodes, cathodes and separators from mechanical influences. They can also bloat as a result of aging processes. Cylindrical hard-case cells are therefore often used in some electric vehicles and in consumer electronics, e-bikes and tools.

"For the handling of round cells in module assembly, we have to offer users grippers that they can freely configure. Depending on the diameter of the individual cells, how they are arranged and how many are to be gripped," says Dr. Mike Fiedler. "Thanks to 3D Print this is easily possible from a batch size of one.”

Electric vehicles worldwide wireless charging with open standards

Electric vehicles worldwide wireless charging with open standards

The user can grip the cells directly at the pole with vacuum suction cups made of the non-marking special material HT1. The material also acts as an insulator. In this way, charged cells can also be safely positioned. A high volume flow is also important here for quick and clean pick-and-place. “Integrated vacuum generators score here. The ejectors have a safety valve so that the vacuum is maintained and handling is secured even without electricity," adds Dr. Fiddler. If the round cells are to be gripped lengthwise, he recommends Magnetic gripper SGM in the high-performance version. A permanent magnet secures handling. As long as the battery shell is ferromagnetic, it will grab.

Manual lifting aids or pick-and-place grippers

Now it's almost done: foils became cells. The cells are grouped into modules, which are now connected into battery packs and equipped with cooling plates, wiring and Electronics be completed. The area gripper FQE is modular and is very well suited for fully automated pick-and-place applications. The area gripper FMP is just as universal. Its sealing foam adapts itself to structured surfaces.

Now it's almost done: foils became cells. The cells are grouped into modules, which are now connected into battery packs and equipped with cooling plates, wiring and Electronics be completed. The area gripper FQE is modular and is very well suited for fully automated pick-and-place applications. The area gripper FMP is just as universal. Its sealing foam adapts itself to structured surfaces.

In the work steps that are not automated, manual lifting aids such as the Jumboflex vacuum lifter relieve the operator. They can Cooling modules or the cover plates, which have to be placed manually on the battery housings at the end. The Safety+ operating unit offers extra safety: The two-hand concept for detaching protects particularly sensitive workpieces when they are set down.

The battery pack is now ready for the leak test, because the housing and cooling system must not show any leaks. The battery management system gets its Software according to car type. The first charging/discharging process in the network takes place under strict supervision. After labeling with warnings and ID tags, the batteries are ready for transport.

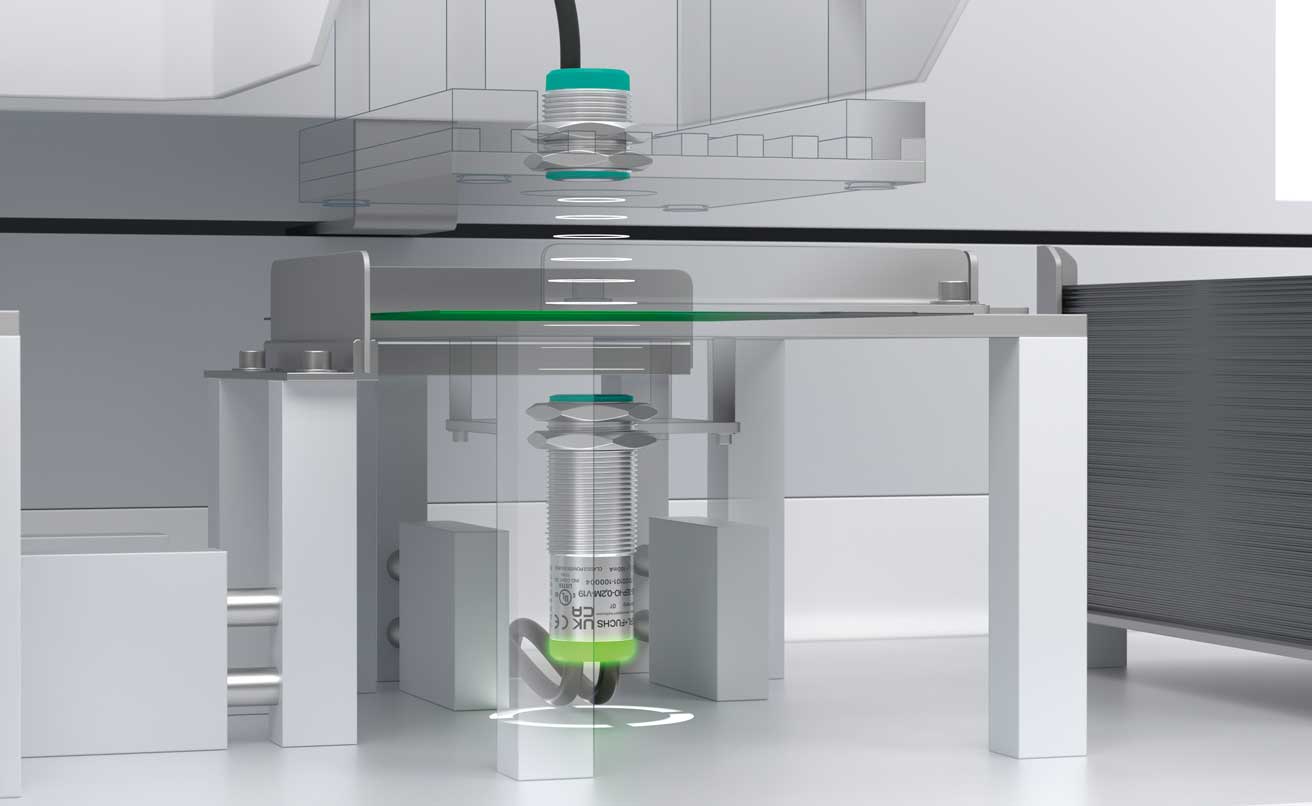

Sensors for relevant process steps in battery production

June 07.06.2022, XNUMX | The efficient control of machines and systems in battery cell production requires many Sensorswho work with different measuring methods. The sensors from Pepperl+Fuchs belong in the Automotive industry to the standard equipment. Based on decades of experience, the company offers all relevant measuring devices for battery production from a single source.

Ultrasonic sensors for distance, distance and level

Ultrasonic sensors for distance, distance and level

Pepper+Fuchs offers a broad portfolio of proven standard devices for the battery production of electric cars customized automation technology for specific applications as shown below as an example:

Rotary encoders for battery production

Coated foils are the most important starting material of the lithium ion battery. Delivered on large rolls, they are unwound from them in battery production. The take-off speed of the rollers is measured with high precision encoder.

Coated foils are the most important starting material of the lithium ion battery. Delivered on large rolls, they are unwound from them in battery production. The take-off speed of the rollers is measured with high precision encoder.

The winding distance and material inventory can be calculated based on the speed. In addition, the value allows the correct web tension to be set for the system and is used to control the material feed through speed control. The new rotary encoder is suitable for this ENI90, which is particularly robust.

Ultrasonic sensor monitors material feed

In the next step, suitable pieces for the batteries to be produced are punched out of the foil webs. These are then assembled into battery cells. The feeding of the punched material for the battery cell is done with ultrasound double sheet sensors like the UDC-18GS monitors.

Equipped with two ultrasonic transducers recognize whether there is one, two or no sheets in the detection area. The process is stopped in the event of double stacking. So the battery capacity is reduced by double layers of the same polarity. Ultrasonic double sheet detection is independent of the environment and the optical material properties. The often shiny films are reliably detected.

Vision sensor checks position

Cells are created from the connected layers of film, which are assembled into finished battery packs. During production, it is important that all the required battery cells are actually present and in the correct position in the specified grid. The vision sensor creates the verification Smartrunner Explorer 3D a precise 3D point cloud image. This compares the actual situation with the required arrangement. Only when everything fits is the manufacturing step for connecting the cells initiated.

Production of e-car batteries in Europe

May 12.05.2022, XNUMX | The production of lithium ion batteries in Europe has so far hardly been worth mentioning. In the wake of electromobility, a turnaround in battery factories is now necessary. Michael Grondowski, Business Development Manager – Central Europe at Mitsubishi Electric Europe BV: “Production plants have been announced for a total annual output of approx 750GWh. That corresponds to approx. 12 million cars”.

With its headquarters in Japan, the group is already supporting the industry in Asia. He also has the automation know-how for the production of the energy storage. From now on, machines, plant manufacturers and battery manufacturers in Europe can also benefit from the special components and technologies.

Servo amplifiers, tension controllers, winding technology and IPC

Battery cell production is precision work and requires the best control technology. For this purpose, the company offers the powerful servo amplifiers of the new series Melservo MR-J5. CC-Link IE TSN, which operates with a bandwidth of 1 Gbit, is used as the automation network. It integrates drive network, fieldbus, safety and open TCP/IP communication.

Bosch News: State-of-the-art semiconductor factory opened in Dresden

Bosch News: State-of-the-art semiconductor factory opened in Dresden

With tension regulators other components are about to be introduced. With precise and stable control processes in the roll-to-roll applications of cell production, they ensure a completely even application of the anode and cathode material to the substrate. Because the layer thickness precision directly influences the performance of the cell. Special winding technology components in the form of magnetic powder brakes and clutches, frequency converters and high-precision servo technology with absoluteEncoder Also support resolution of 26 bits per motor revolution.

"The basic requirements for ever higher quality battery cells are a powerful network for system monitoring and solutions such as the AI package for the Melpic industrial computer' says Mr. Grondowski. "This allows quality data to be evaluated in real time before it negatively affects the product."

FAQ

Where are batteries manufactured in Germany?

There are various locations in Germany where batteries are produced. Some of the most well-known locations are:

- BASF recently started producing cathode materials for lithium-ion batteries in Schwarzheide, enough for up to 400.000 electric car batteries per year.

- Bosch, one of the largest automotive suppliers in the world, has plans to manufacture solid-state batteries and operates research and development centers in Germany.

- BMW in Leipzig produces the battery modules for the iX and i4 models. In Irlbach and Straßkirchen, Lower Bavaria, BMW is planning to build a battery assembly plant. BMW opened a new competence center for the production of battery cells in Parsdorf near Vaterstetten in 2022.

- catl: The Chinese battery manufacturer Contemporary Amperex Technology Co. Limited (CATL) is building a battery factory in Thuringia to produce lithium-ion cells for electric cars.

- Daimler/Mercedes Benz: Daimler's Accumotive subsidiary operates production in Kamenz, Saxony, and is planning additional factories in Germany.

- microvast, Texas battery manufacturer, assembles battery modules at its European headquarters in Ludwigsfelde near Berlin. The cells come from Microvast Power Systems in China.

- Northvolt, the Swedish battery company, is planning to build a battery factory in Heide, Schleswig-Holstein, for the production of lithium-ion cells.

- Porsche is planning to enter battery production with a battery factory in Tübingen, Swabia, where high-performance cells will be produced. Svolt Energy Technology, a Chinese company originally a subsidiary of Great Wall Motors, is planning to build a battery cell factory in Saarland.

- Terra E is based in Frankfurt am Main and plans to manufacture lithium-ion cells on a large scale.

- Varta, a traditional German company specializing in small lithium-ion cells, operates production facilities in Ellwangen, Nördlingen and Dischingen.

- Volkswagen operates a battery factory in Braunschweig that will produce 600.000 electric car batteries annually once full capacity has been reached. The car manufacturer also plans to set up its own production in Salzgitter.

- Tesla plans to manufacture batteries as part of the construction of its Gigafactory Berlin in Grünheide, Brandenburg.

What battery technologies are there for electric cars?

The lithium-ion battery is the most commonly used in electric cars. But there are other technologies as well. Here are some of the most common battery types:

- Lithium Ion Batteries (Li-Ion): This type of battery is currently the standard for electric cars due to its high energy density, relatively light weight and ability to go through many charge cycles without significant loss of capacity. They come in various chemistries such as lithium nickel manganese cobalt (NMC), lithium iron phosphate (LFP), lithium cobalt oxide (LCO), and lithium titanate (LTO). They all differed in their performance characteristics in terms of energy capacity, longevity, safety and cost.

- Nickel Metal Hydride Batteries (NiMH): They were used in previous generations of hybrid vehicles such as the Toyota Prius. NiMH batteries have a lower energy density and heavier weight than lithium-ion batteries, but offer robust and reliable performance and are tolerant of harsh operating conditions.

- solid state batteries: This emerging battery technology has the potential to increase energy density and improve safety by replacing liquid electrolytes with solid materials. Several companies and research institutes are working on the development of solid-state batteries for electric cars, including Toyota, BMW and Quantum Scape.

- Sodium Ion Batteries: The alternative technology is under development. They use sodium instead of lithium, which is plentiful and cheaper. They could be a low-cost alternative to lithium-ion batteries, although they currently have lower energy densities.

Who is building the new super battery?

The world's largest battery manufacturer catl has introduced the “Shenxing” energy storage system, a super battery with the shortest charging times of ten minutes. The new battery is intended to charge energy for 400 kilometers at the charging stations.

Who is the largest battery manufacturer?

The largest battery manufacturer in the world is Contemporary Amperex Technology Co., Ltd. (CATL), a Chinese company recognized as a leading supplier of lithium-ion batteries for electric vehicles and energy storage systems. (Source: Global Top 10 Battery Companies 2023 Blackridge Research & Consulting)

Source: This article is based on information from the following companies: Mitsubishi Electric, Novalis, Pepperl+Fuchs, Schmalz, Siemens, Weiss Technik.

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.