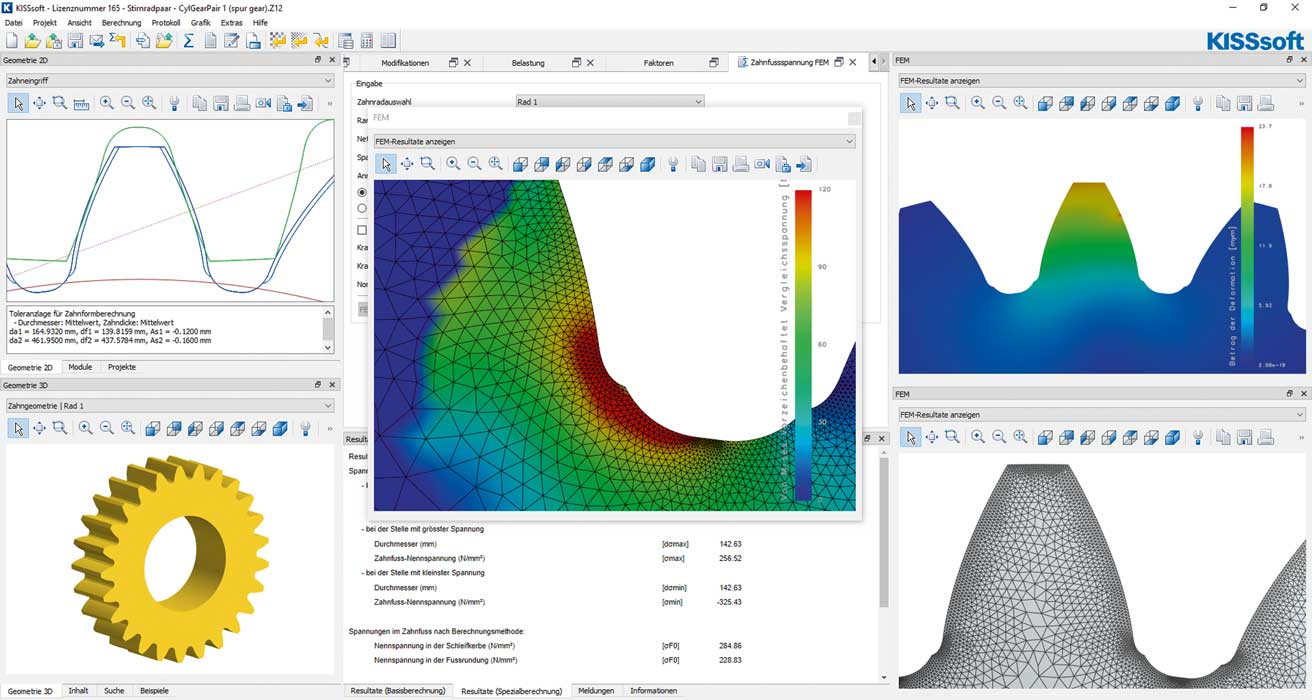

Combined FEM and standard calculation in Kisssoft

- Details

- Hits: 8845

If the designer designs a new machine, he has to use the individual ones Machine Elements dimension. There are two concepts for analyzing it. FEM as the finite element method or the Machine elements method or the analytical or standardized method. In KISSsoft the developer finds a combination of both.

The machine element method is based on standardized calculation rules. The finite element method FEM and the standardized methods do not compete with one another, but complement one another. The combination in the calculation programs Kisssoft and KISSsys combine standardized methods with FEM calculations at different levels of analysis. Thanks to this interaction, the very fast standardized methods generate input data for the fine element calculation without additional modeling effort.

FEM calculations of wheel body deformation

The results of the FEM calculations of the deformation of the wheel bodies as well as the 2D and 3D Tooth root stresses are now displayed directly in Kisssoft. The user receives a significantly faster assessment of the critical components and critical points. In addition, control over the FEM calculation is improved.

Interface for easier bearing calculation of gearboxes

Interface for easier bearing calculation of gearboxes

As a Evaluation graphics such as FEM mesh, deformation and stress according to von Mises and other graphics are available. Postprocessing with Salome is available for a detailed evaluation.

General technical knowledge

What is FEM?

The finite element method, in short FEM is a numerical method with which the physical behavior of a component can be determined under arbitrarily changeable boundary conditions. With the finite element method, physical deformations or strengths of a component with complex geometries are often determined by the action of e.g. B. examined by loads. The finite elements in this process are many small triangles, squares or other geometric shapes into which a component is divided. The results from the individual elements are finally put together. The user receives information about the behavior of the entire component. In this way, deformations and other properties can be calculated more easily, which is now done using computer programs.

You might also be interested in...