Components for rubber metal buffers for vibration protection

- Details

- Hits: 6635

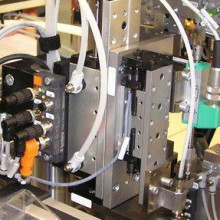

Wherever drives are installed and technical components are in motion, designers have to vibration build into your construction. Helmut Rübsamen produces high-precision mountings and bearing shells for well-known manufacturers in the industry Rubber metal buffer. They are used in mechanical engineering, Automotive industry, Rail technology, shipbuilding and energy technology.

Rubber metal buffers ensure in larger kinematic constructions such as engines or compressorsen for Operational safety and value retention. They can be found in conveyor and transport systems, chassis from Construction or rail vehicles, drive trains from Wind Turbines or for the storage of heavy machinery and marine diesel. Rubber-metal buffers dampen vibrations that occur there, absorb shock loads, ensure smooth running and reduce the wear and tear on sensitive functional components.

For this purpose, Rübsamen produces high-precision mountings as well as housings and bearing shells for them vibration. They consist of heavy-duty steel and stainless steel sheets with a wall thickness of 1 to 6 mm. In terms of dimensions, they cover a wide range. Ring-shaped rubber-metal elements with diameters from 40 to 1000 can thus be realized.

Rubber metal buffers with pretension

The components for the rubber metal buffers are delivered directly to the rubber coating specialists or the vibration damper manufacturers. After being there with long lasting Quality rubber linings have been equipped, they receive the required preload with Rübsamen.

The components for the rubber metal buffers are delivered directly to the rubber coating specialists or the vibration damper manufacturers. After being there with long lasting Quality rubber linings have been equipped, they receive the required preload with Rübsamen.

The sheet metal forming specialist produces massive pieces in its main plant in Bad Marienberg Abutment made of steel, which are used in onshore and offshore wind turbines after the rubber elements have been embedded. These molded parts are made of high-strength steel, are 240 x 190 mm in size with a wall thickness of 7,5 mm. They have a mounting plate with holes and a conical cone into which the rubber element will later be fitted.

Such and similar molded parts are in Metal spinning process mostly made entirely from one piece. This cold forming technology, also known as extrusion, is extremely resource-saving and does not require an expensive moldtools out. It is therefore particularly energy-efficient and economical when producing small or medium-sized quantities.

For recordings, bearing shells and housings with rotationally symmetrical geometry the metal spinning process is also suitable. Because such components can be made completely seamless and have the best strength values. This is because the material structure of the steel is not exposed to any significant thermal stress during shaping.

Wave spring or not? That is the question of Gutekunst here

Wave spring or not? That is the question of Gutekunst here

Deep drawing and welding up to a lot size of 100.000

If vibration dampers up to a lot size of 100.000 are required, Rübsamen can use deep drawing in accordance with DIN 8584 and is well equipped here. With a pressing force of up to 600 tons, the company produces housings on its deep-drawing machines, Warehouse and holders for rubber-metal buffers with wall thicknesses from 0,5 to 15 mm and diameters from 20 to 2000 mm or edge lengths of 2000 x 1500 mm.

You might also be interested in...

Safety dampers protect scabies sorting plant for copper

Sorting system for packet rush equipped with shock absorbers

Miniature shock absorbers and structural dampers in two linear module examples

Viscoelastic shock absorbers for emergency stop