Switches, buttons, controls for machines

- Details

- Hits: 3415

The controls, switches and buttons portfolio from Schmersal for the machine or system in industry focuses on intelligent sensor technology and decentralized automation solutions. The products support modular systems, reduce commissioning times and even cover hygienic design requirements. Below we present them to you New Products and their use.

Contents

Door handle system displays machine statuses

April 08.04.2024, XNUMX | Schmersal presented at the Hannover Messe 2024 his new one DHS door handle system. The handles combine the functions of a robust door handle with the display of various machine states. The color of the handle lighting provides information about this. The universally designed handles can be used together with the interlock AZM40, with RSS36 and RSS260 safety sensors or as a stand-alone solution.

April 08.04.2024, XNUMX | Schmersal presented at the Hannover Messe 2024 his new one DHS door handle system. The handles combine the functions of a robust door handle with the display of various machine states. The color of the handle lighting provides information about this. The universally designed handles can be used together with the interlock AZM40, with RSS36 and RSS260 safety sensors or as a stand-alone solution.

The handles signal different Machine states large area over 7 colors. These can be controlled individually and defined as machine states. An additional push button can be individually adapted to customer requirements based on the colored button caps included in the delivery. For example, the push button can take on the task of a reset function or a request to open the protective door.

The DHS help saves you from having to install additional door handles and indicator lights. It is designed for integration into 40mmProfile systems designed. With its flat design, the new BDF40 control panel adapts perfectly to the AZM40 safety locking device. Two variants are available: With or without an emergency stop function, the handles offer interchangeable, colored button caps for illuminated pushbuttons or unilluminated pushbuttons.

Using a connector, the control panel can be seamlessly integrated into the door system with the AZM40 safety locking device and the DHS door handle. But it can also be used as a standalone Control panel be installed. The 12-pin M12 connection allows for quick and error-free installation. Optional MS mounting kits are available for this purpose.

Controls for food technology

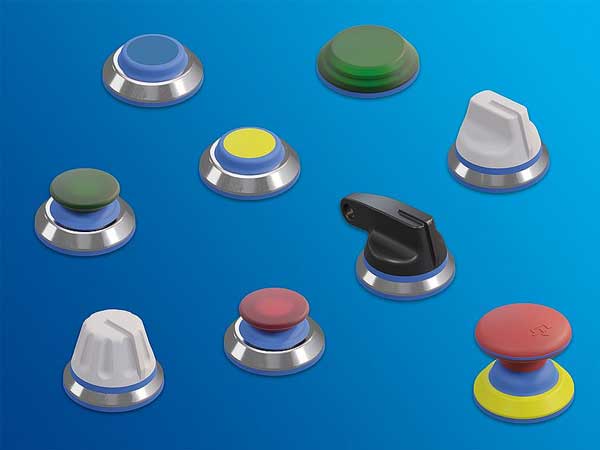

November 21.11.2022, XNUMX | With the H series control element Schmersal a complete product range of command and signaling devices for hygiene-sensitive areas of application with a focus on Food Processing before. Among the characteristic properties of these controls include gap-free transitions of sealing elements and surfaces and the absence of protruding parts. The switches and buttons are so easy to clean.

November 21.11.2022, XNUMX | With the H series control element Schmersal a complete product range of command and signaling devices for hygiene-sensitive areas of application with a focus on Food Processing before. Among the characteristic properties of these controls include gap-free transitions of sealing elements and surfaces and the absence of protruding parts. The switches and buttons are so easy to clean.

The control element series meets the requirements of DIN EN ISO 14159 (Safety of machines - hygiene requirements for the design of machines) and the specifications of the new version of EN 1672-2 (food processing machines - general design principles). This standard makes very precise specifications for the hygienic design of all operating elements on the human-machine interface (HMI) of a food processing machine. The new regulation 10/2011/EU, which sets the requirements for the material Selection formulated for this area of application.

The new H-series replaces the N-series, which is the most popular worldwide HMI found in applications in food processing plants. The new control device program contains various types of switching devices such as pushbuttons, indicator lights, selector switches, main switches and emergency stop devices.

Hygienic design and modular construction

The design of the switches, buttons and other operating elements corresponds to the "Hygienic Design" construction principle. The controls are fully modular. Thanks to snap-on contact carriers and individual contacts that can be combined using the piggyback principle, the operating elements can be installed quickly and easily, are highly flexible and designed for pre-wiring. In addition, they are sealed so well that they can withstand regular high-pressure cleaners or aggressive cleaning agents.

Graphic HMI operator terminals for industrial automation

Graphic HMI operator terminals for industrial automation

Overall, the H program for operating a machine includes 147 different devices, including 26 mushroom pushbuttons, 24 two- and three-position selector switches and four rotary potentiometer switches. The designer in food technology is free to choose which type of control elements he uses to operate the HMI. The variety of different hygienic switching devices makes the H range unique. In addition, the controls can be ordered with individual laser marking, for example as an OEM version with a logo.

You might also be interested in...

This is how you build a collaborative robot cell

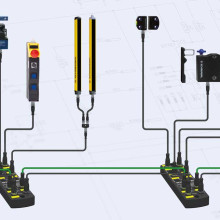

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing

Relays & Switches | Discover the possibilities!

Sylvia Blömker is PR Manager at the Schmersal Group, Wuppertal.