Telescopic rails up to 136 kg load capacity for furniture and industry

- Details

- Hits: 5652

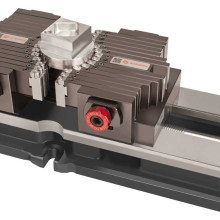

The Heinrich Kipp Werk replaces its range of telescopic rails with new products. It stands now telescopic rails with a load capacity of up to 136 kg and rail lengths of up to 910 mm are available. The designs are as varied as their potential applications.

"Telescopic rails are suitable for a wide variety of applications," says Samuel Rasch, Product manager at Kipp. "They are not just for z. B. drawers as partial or full extension are interesting in the furniture industry, but are also used as pull-outs for drawers and other industrial components in the commercial sector, where the load is greater. ”The structure is always the same. The telescopic rails consist of two or more nested, ball-bearing guide rails. These can be pulled out telescopically. As an alternative, they are therefore also called pull-out guides or ball-pulling guides.

Individual control panels as special solutions from a single source

Individual control panels as special solutions from a single source

The possible Load on the telescopic rails depends on various influencing factors such as rail length, stroke, number of cycles, material, installation method and system assembly. "We differentiate between three types of extension: partial extension, full extension and over-extension with different rail lengths," explains Mr. Rasch.

The different functions of telescopic slides

In the portfolio of the Workholding Specialists Heinrich Kipp there are telescopic rails with different Features. There is a pull-out rail with tumbler that fixes the guide in the closed position. There are drawer runners with soft closing for gentle closing. These catch the movement when closing and the guide moves automatically to the end position. A defined force must be overcome to open it. This avoids unintentional processes.

In the telescopic rails with self-closing a spring mechanism pulls the guide in completely when it is pushed in before reaching the end position. Telescopic rails with an integrated opening mechanism extend the guides independently and almost noiselessly with a light tap. Other telescopic rails have a separable inner rail to detach the inner rail profile. In this way, the movable element can be completely removed from the guide.

Clamping technology for workpiece, device and machine tool

Clamping technology for workpiece, device and machine tool

Three different Rail types partial extension, full extension and full extension are available to the user during assembly. He can choose between surface mounting, groove mounting and side mounting. All telescopic slides from Heinrich Kipp Werk are tested according to DIN EN 15338 and are available from stock.

You might also be interested in...

This snap lock locks securely

clamping technology | Intelligent, safe, efficient!

Ergonomic controls and standard parts

Indexing bolts / locking bolts from Kipp

Heinrich Kipp work | Inventor of the spaetzle machine