DC motor and other drives for medical technology

- Details

- Hits: 10813

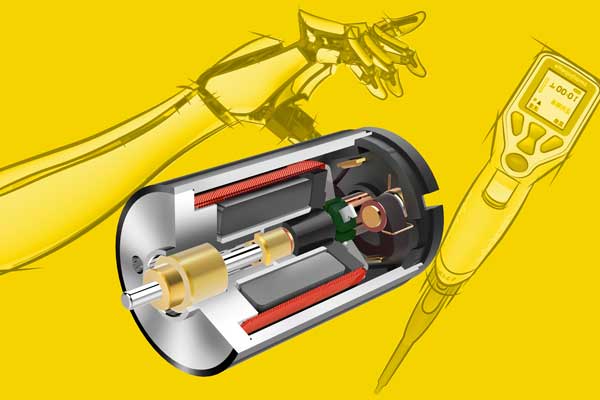

koco Motion offers a comprehensive range of products Drive Technology for the currently particularly booming one Medical Technology. With the DC motor, bell rotor motor, brushless DC motor, precision gear motor, precision servo motor and miniature stepper motor portfolio of Constar, almost all developer wishes can be fulfilled. Medical pumps, surgical instruments, respirators or prostheses, for example, are possible applications.

Content of the technical article

- Koco Motion masters Covid-19

- Individual adjustments as a daily business

- Optimism and anticipation for what's to come

Koco Motion masters Covid-19

“Thanks to our high delivery capacity, we were able to meet the needs of medical technology projects, particularly with short delivery times. We were also able to win new projects and customers here who needed support in the production of masks and rapid tests, for example. We were also able to meet the needs of global sub-suppliers for complete medical technology components, ”says Olaf Kämmerling, Managing director of koco Motion GmbH in Dauchingen.

“Thanks to our high delivery capacity, we were able to meet the needs of medical technology projects, particularly with short delivery times. We were also able to win new projects and customers here who needed support in the production of masks and rapid tests, for example. We were also able to meet the needs of global sub-suppliers for complete medical technology components, ”says Olaf Kämmerling, Managing director of koco Motion GmbH in Dauchingen.

Nevertheless, the beginning of the pandemic bumpy at first, even for the drive specialists. "The year 2020 was characterized by a slump in many areas of our customers in the first quarter, which was followed by numerous bad news.

In some cases, they were not able to meet the agreed purchase quantities and the situation was very opaque,” Mr. Kämmerling thinks back. In addition, there were delivery bottlenecks due to the Asia lockdown as well as bottlenecks in the global supply chain.

How to make a protective mask in your own production

How to make a protective mask in your own production

The one that then begins Medical technology boom has also given the company a deeper insight into market needs and has now allowed Koco Motion to align itself with them. At the sister company Koco DC Motion in the USA, the medical technology sector now generates more than 50% of total sales.

The one that then begins Medical technology boom has also given the company a deeper insight into market needs and has now allowed Koco Motion to align itself with them. At the sister company Koco DC Motion in the USA, the medical technology sector now generates more than 50% of total sales.

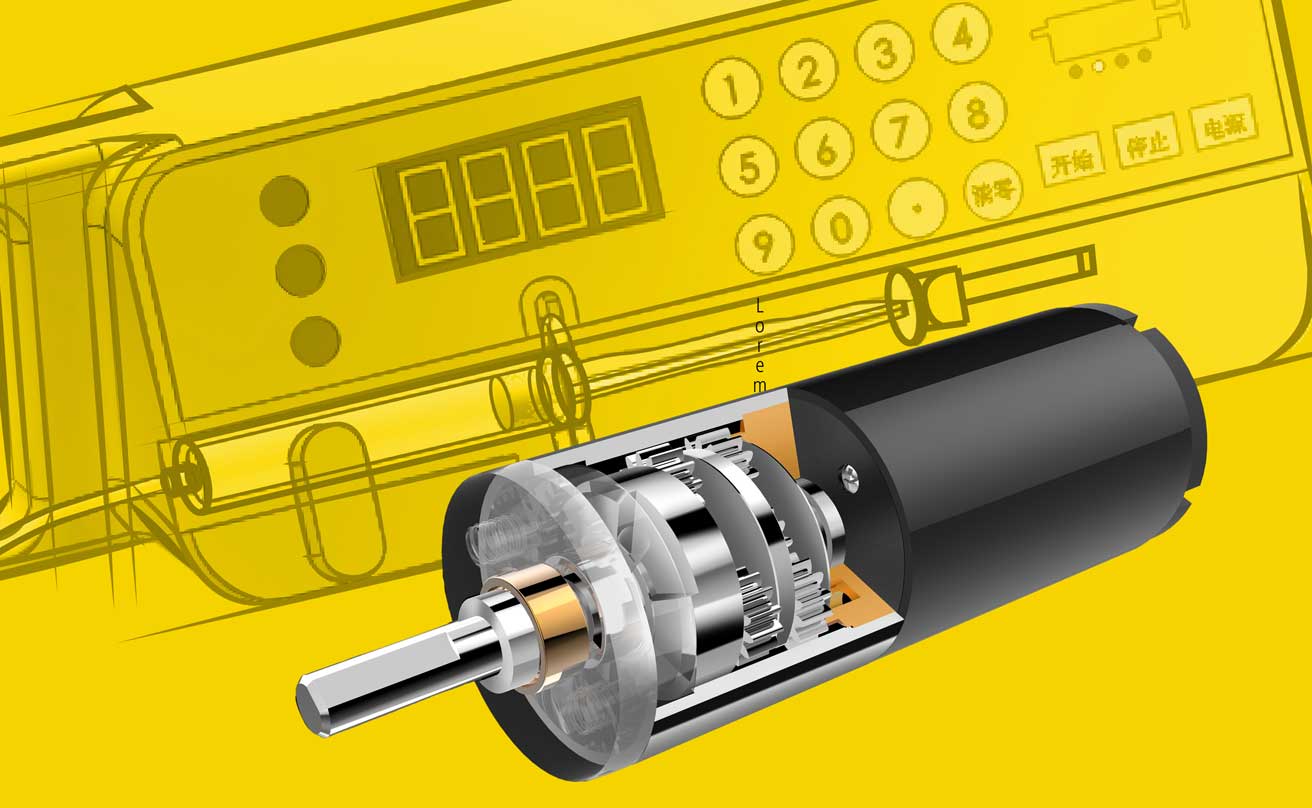

Quality electric motors from Shenzhen

The drive specialist works closely with the offer for medical technology Constar Micromotor Co., Ltd. from Shenzhen, China together. The company, founded in 2000, has specialized in micromotors and drive solutions based on them. More than 40 patents have already emerged from this engineering. Constar offers high product quality in accordance with the IATF16949 standard.

The medical technology portfolio of the Asians is broad. It contains, among other things, series of brushless DC motors (BLDC), bell-type motors, precision gear and servo motors and miniature stepper motors. They are all used in medical devices, as the following examples illustrate:

DC motor for medical pumps

Servomotor gear combinations were specially developed for the insulin pump. The compact one Insulin pumps DC motor allows small, precise and permanent infusions. The amount of insulin to be pumped can be adjusted using various gear stages and encoder resolutions.

Servomotor gear combinations were specially developed for the insulin pump. The compact one Insulin pumps DC motor allows small, precise and permanent infusions. The amount of insulin to be pumped can be adjusted using various gear stages and encoder resolutions.

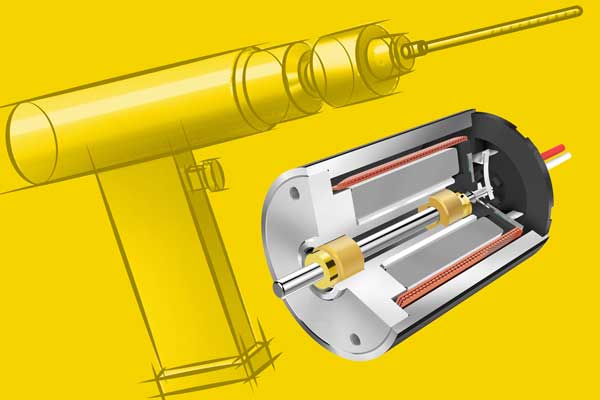

A precise bell-type rotor motor is suitable for driving in one Vacuum pump. The compact 9-part collector offers a low torque ripple (ripple) and low commutation current peaks (spark erosion). Together with the ironless wound rotor, the DC motor generates a high degree of efficiency and offers a long service life.

For the Infusion pump different DC motors are predestined like iron armature or bell-type gear combinations as well as small stepper motors. Because the electric motors offer high positioning and repeat accuracy, the infusion pumps pass the strict controls of the infusion quantities over their service life.

Adaptive exoskeleton for the stroke patient

Adaptive exoskeleton for the stroke patient

A gear motor takes care of that in a micro injection pump Injecting the medication precisely controlled. The electric motor is also characterized by its high repeatability, it is compact and very precise.

BLDC electric motor for ventilators, surgery and prostheses

For Ventilators Koco Motion has a brushless motor in its range. The DC motor keeps the ventilator air pressure stable. The noise level is barely audible and the service life is long.

For Ventilators Koco Motion has a brushless motor in its range. The DC motor keeps the ventilator air pressure stable. The noise level is barely audible and the service life is long.

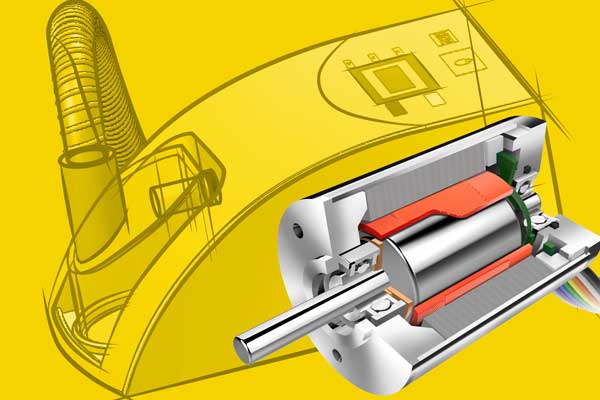

For surgical equipment As used for cutting, milling or drilling, the drive specialist has developed special brushless and ironless motors. These drives offer high torque and efficiency as well as excellent dynamic / static speed control.

The engines for surgical robots have an ironless winding and offer high torque and speed. Thanks to the fast response speed, the DC motor can position precisely. In this way, the robots can implement precise and complex movements.

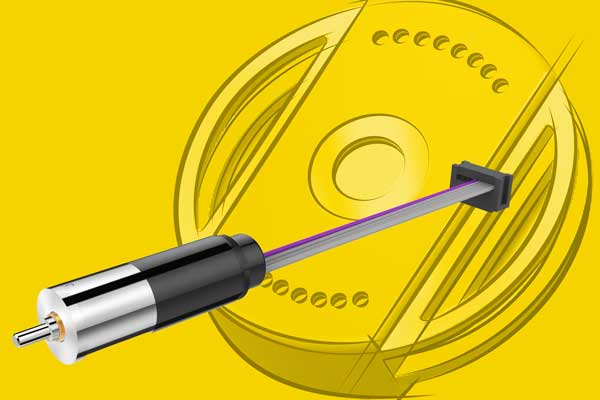

At a Multi-leaf collimator for radiation therapy, the movement of the lamellae inside defines the radiation field. A compact servo motor accelerates the movement due to its high power density and high reaction speed. The combination with a high-resolution encoder reliably guarantees the precise positioning of the slats.

IR camera to measure fever detects Covid-19 sufferers

IR camera to measure fever detects Covid-19 sufferers

In prostheses come bell runners and brushless DC motors combined with gearboxes. The advantages of the bell-type rotor come into play here: low weight, no detent torque, high efficiency and stable torque with very good controllability. With this DC motor, the movements of artificial joints can be realized well. Thanks to these properties, users can move naturally, stably and powerfully with their prosthesis.

Stepper motor and servo motor for laboratory and analysis devices

Koco Motion offers various drives for the mechanics of Blood analyzers. Stepper motor and servo motor ensure automated and precise positioning. Here, too, the devices have a long service life and offer reliable operation.

Medical technology grippers: concentrated know-how for the megatrend

Medical technology grippers: concentrated know-how for the megatrend

For the centrifuge the brushless internal or external rotor motor with high torque and speed is used. They increase the efficiency of the centrifuges and use the maximum centrifugal speed. The separation factor of the centrifuge is improved and the maintenance costs are reduced.

In Pipettes the bell runners together with encoders provide the necessary precision. Maintenance-free and reliable, they also maintain the speed and accuracy of the dosing when pipetting.

Complex applications and stand-alone devices

Stepper Motors with and without control are also used in medical technology. Here they are very well suited for positioning, especially where gearboxes are undesirable due to tight installation space or noise. This also applies if positioning is to take place without an encoder or limit switch. Koco Motion almost always has a suitable drive ready for this. Examples of use include the blood analysis devices described above or medical pump technology.

Stepper Motors with and without control are also used in medical technology. Here they are very well suited for positioning, especially where gearboxes are undesirable due to tight installation space or noise. This also applies if positioning is to take place without an encoder or limit switch. Koco Motion almost always has a suitable drive ready for this. Examples of use include the blood analysis devices described above or medical pump technology.

For Stand-alone devices or highly complex applications, the Lexium MDrive and MDrive from Schneider Electric are often used. An integrated steering takes on the control tasks here and controls and operates several units and processes at the same time.

Last but not least, the simple programming and control offers Kannmotion platform by Adlos and Koco Motion. Their special feature is the ability to customize hardware and software. In larger quantities, Kannmotion offers a particular benefit if it is specially adapted to the application. Then it can only do as much as it needs to be able to do, and that is very cost-effective. Despite their simplicity, the compact motors with integrated control and closed loop function are suitable for a wide range of applications.

Individual adjustments as a daily business

"Customization are our daily business and are part of the challenges for a good partnership ”, says Olaf Kämmerling.

"Customization are our daily business and are part of the challenges for a good partnership ”, says Olaf Kämmerling.

In medical technology, a standard product rarely meets the requirements of all applications. If one application requires particularly low-noise operation with high energy efficiency, the next application may need a strong and robust drive. If you want to reconcile the two, an application-specific adaptation is necessary.

"In our efforts to optimally adapt the drive to the application, this often collides with the budget we are striving for," says Olaf Kämmerling, describing the occasional dilemma. “The decision about the engine technology is often in the foreground. During the selection, important foundations for costs and benefits are set. The earlier we can get into the projects, the more options there are for optimizing the drive. The degrees of freedom continue to decrease in the ongoing project, while the compromise finding increases, ”explains the managing director.

DC motor as an all-round talent for countless applications

DC motor as an all-round talent for countless applications

Possible adjustments that have already been made are, for example: B .:

- Winding resistance

- Efficiency

- Brush

- Bearing types (ball bearings, plain bearings)

- Torques

- Attachments (brakes, gears, encoders, feedback systems, magnets, spindles, nuts, etc.)

- Shafts, shaft feedthrough, shaft contour

- Cables, plugs, connections

- flanges

- Outer contours

- Coatings

- Hardware, software

- Sensors like temperature sensor, Hall sensor, etc.

Optimism and anticipation for what's to come

Koco Motion reacted very quickly to the current situation with measures to address the pandemic. To the Employees To protect against Covid-19 in the workplace, the infrastructure has been adapted. Home office for some and distance, masks & Co. for a small team on site in Dauchingen are some of the measures.

Digital admission control for exact counting of people

Digital admission control for exact counting of people

"We are in the fortunate positionto have a very diverse clientele. This means that we can largely absorb the decline in one sector with the gains from other sectors, ”summarizes Olaf Kämmerling. “Overall, Koco Motion was even able to close 2020 with growth. Even if there are still many challenges to overcome before we leave this crisis behind us, we look forward to the time after that. For the future, we expect that our new customers will continue to work with us. "

You might also be interested in...

stepper motor | Precise low cost positioning

servo motor | Electric motor with control electronics

Koco Motion | System house for drives

Now also a large servomotor portfolio up to 8 kilowatts

Servo motor made of DC / stepper motor with controller and encoder

DC motor as an all-round talent for countless applications

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.