Equipment for stubble cultivation in agriculture, so-called cultivators, used to be used primarily for weed control. Today the main benefit is to loosen the arable land, mix in organic matter and prepare it for the next sowing. The "Karat 9" from Lemken is an intensive cultivator that can be used for shallow, medium and deep work. Lubrication-free plastic plain bearings perform at the bearing points Igus their reliable service.

Equipment for stubble cultivation in agriculture, so-called cultivators, used to be used primarily for weed control. Today the main benefit is to loosen the arable land, mix in organic matter and prepare it for the next sowing. The "Karat 9" from Lemken is an intensive cultivator that can be used for shallow, medium and deep work. Lubrication-free plastic plain bearings perform at the bearing points Igus their reliable service.

The Lemken GmbH and Co. KG from Alpen was founded by 1780 and since then has been a family-run company specializing in the production of agricultural equipment for soil cultivation, sowing and plant protection. Today, the company employs over 1000 employees worldwide. In addition to Germany, key markets are France, Canada, Russia and China.

The Lemken GmbH and Co. KG from Alpen was founded by 1780 and since then has been a family-run company specializing in the production of agricultural equipment for soil cultivation, sowing and plant protection. Today, the company employs over 1000 employees worldwide. In addition to Germany, key markets are France, Canada, Russia and China.

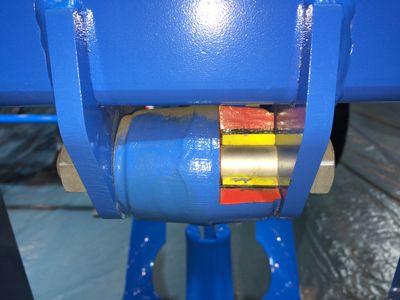

One area is made up of stubble cultivators, so-called cultivators and short disc harrows. These serve today mainly for conservation tillage and stubble cultivation. The Karat 9 is an intensive cultivator that penetrates deep into the soil between 5 and 30 cm, optimally incorporating organic matter. During use, it may happen that larger stones in the ground are in the track of the tractor and its soil tillage implement, which must not hinder the workflow. As a result, the Karat 9 has maintenance-free overload elements, allowing the tines that work in the ground during normal operation to automatically dodge backwards and forwards, and then automatically return to their working position.

The whole world of igus robots

The whole world of igus robots

Problem Lack lubrication is a thing of the past

The overload element is maintenance-free thanks to the use of lubrication-free plastic plain bearings from Igus GmbH in Cologne. “In the past, insufficient lubrication was a real problem in cultivator applications,” explains Lars Heier, Marketing Manager at Lemken. “With metallic solutions, the bearings here would have to be lubricated once a day so that the bearings can do their job properly.

The overload element is maintenance-free thanks to the use of lubrication-free plastic plain bearings from Igus GmbH in Cologne. “In the past, insufficient lubrication was a real problem in cultivator applications,” explains Lars Heier, Marketing Manager at Lemken. “With metallic solutions, the bearings here would have to be lubricated once a day so that the bearings can do their job properly.

Depending on the working width of the cultivator, that means up to an hour of work per day. ”With the“ Iglidur ”high-performance materials, subsequent lubrication is completely unnecessary, as the bearings contain self-lubricating solid lubricants. At the same time, the iglidur plain bearings easily withstand the high forces in the cultivator's overload element.

Years of successful cooperation

In the year 2008 the Karat was the first application of Lemken, which was realized with lubrication-free Iglidur plain bearings. Previously, the specialist in agricultural technology used DU bushes in his machines. "At the karat cultivator, everyone smiled at us at the beginning, because we wanted to use plastic at the depository," Lars Heier admits. "Today, depending on the load, the plastic plain bearings only need to be replaced every few years, which adds a further cost advantage in addition to the saved lubricant."

Potato harvester reliable again after conversion from freewheel

Potato harvester reliable again after conversion from freewheel

Since this pioneering project, numerous other Lemken devices have been equipped with Iglidur plain bearings. The cooperation between the two companies works very well: Igus tests its own materials very extensively in its own test laboratory in Cologne, where different bearing materials are combined with different shaft materials in order to be able to calculate the coefficient of friction and wear as precisely as possible.

Lemken also tests the products specifically for their requirements at their own location in the Alps. "It's very important for us to work with a local company. That's the only way to get together quickly and easily to discuss new projects or try new solutions, "says Lars Heier. In order to be able to act locally with customers, the Cologne-based plastics specialist employs qualified experts in the field, who are on hand to assist customers on site.

Lemken also tests the products specifically for their requirements at their own location in the Alps. "It's very important for us to work with a local company. That's the only way to get together quickly and easily to discuss new projects or try new solutions, "says Lars Heier. In order to be able to act locally with customers, the Cologne-based plastics specialist employs qualified experts in the field, who are on hand to assist customers on site.

In addition, there are industry specialists at the main location in Cologne, who work precisely in their respective areas and support projects, including in the agricultural sector. In Cologne, one is also happy about the uncomplicated cooperation and the openness of an agricultural company for plastics technology. "I think it's great that Lemken also admits here 'that it uses plastic at storage sites,'" emphasizes Florian Blömker, a field technician at Igus. "Because plastic is often viewed with suspicion in agriculture. And if a storage location does not need to be lubricated at all, users are often skeptical. "

Plastic bearings withstand high forces

Especially in agriculture often act high forces, because it works with heavy equipment, which must be very robust. That's why metal bearings were the first option in the past. Especially with pivoting movements, however, these bearings have a very limited lifespan, since lubricants can not be evenly distributed and only the same locations on the bearing are claimed. This is where plastic plain bearings have their advantages, since they do not have such a lot of slewing motion and no lubricant can be displaced.

Especially in agriculture often act high forces, because it works with heavy equipment, which must be very robust. That's why metal bearings were the first option in the past. Especially with pivoting movements, however, these bearings have a very limited lifespan, since lubricants can not be evenly distributed and only the same locations on the bearing are claimed. This is where plastic plain bearings have their advantages, since they do not have such a lot of slewing motion and no lubricant can be displaced.

Another advantage is the dry running of the bearings, since no dirt can accumulate on them. 47 catalog materials are available for a wide variety of requirements, including high-load applications such as those found in the agricultural sector. In the Karat 9 cultivator, however, plain bearings made of the all-rounder Iglidur G, which withstand the compressive strength of 80 MPa, have already proven themselves. For higher loads, there are also catalog materials up to 120 MPa, such as Iglidur Q2 or Iglidur TX1 to 250 MPa. In addition to the standard program, however, special solutions are also possible via 100 with which even more specific applications can be realized.

Housing bearing replacement saves significant TCO

Housing bearing replacement saves significant TCO

For future applications, Lemken is sure that they want to put the benefits of lubrication-free plastic plain bearings. "Working time alone, which users save thanks to maintenance-free plain bearings, is a very strong argument for plastic plain bearings today," explains Lars Heier. "We will continue to rely on Igus bearings in the future as well. Because what has proven itself is maintained by us, that's for sure. "

You might also be interested in...

Sustainability plastics – CO2 neutral with recycling

Igus linear guide quiet, resistant, maintenance-free

Electrical Wires | From cable to assembly

Cobot | Discover collaborative robots as a new employee

Igus energy chain: stable, recyclable, plastic.