Industry News: News and other company news

Industry news from the companies

- Details

- Category: Plain bearings and roller bearings: news for your design

- Hits: 22733

In special machine construction, the components are required in application-specific designs, the smallest batch sizes and at economic conditions. Misumi meets this need with a portfolio of mechanical machine elements from over 40 product groups that is looking for its equal. The article describes in particular the ball bushing program with its innovative lubrication technology and the range of plain bearings, which are suitable for a wide variety of applications.

In special machine construction, the components are required in application-specific designs, the smallest batch sizes and at economic conditions. Misumi meets this need with a portfolio of mechanical machine elements from over 40 product groups that is looking for its equal. The article describes in particular the ball bushing program with its innovative lubrication technology and the range of plain bearings, which are suitable for a wide variety of applications.

With the new edition of the main catalog "Mechanical standard components for special machine construction & assembly automation" published at the end of March, Misumi has brought various new products onto the market. This includes, for example, maintenance-free plain bearing bushes Gland, narrow and wide plain bearing bush housings in a compact design as well as various versions of easy-to-assemble housing and flange bearings.

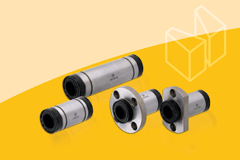

In addition to the variety of products from a single source, the so-called "Flexible Configuration & Sizing" is one of the special features of the offer. With the extensive options for shaping and the graduated variations with dimensions in steps of up to 0,01 mm, all components can be adapted to individual requirements and tailored to the construction, instead of having to modify the component accordingly. This also applies to the linear ball bearing product group. Due to the low friction and high accuracy, shaft guides with ball bushings can be used widely: Systems for semiconductor production, in food packaging machines or in the production of electronic devices are just some of the possible areas of application. Whether standard or compact, closed, open or rustproof - the catalog provider has various versions of linear ball bearings in its range.

By default, the ball bushings are wetted with anti-rust oil before delivery; exceptions are versions with a preselected lubrication type (optionally L, G or H) as well as the MX linear ball bearing with lubricant reservoir - one of the novelties from the previous year - in single or double bearing version, with or without flange (flush, recessed or centered) ) as well as with round, square or rectangular flange form; the various versions are usually available from stock.

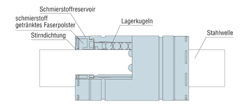

Lubricant over fiber pad by capillary action

These products, for which a patent is pending, are equipped with a depot from which lubricant is released onto the bearing surface of the bearing balls via a fiber pad by capillary action. A face seal on the ball bushing prevents the lubricant from leaking out. In this way, the oil film between the shaft and the bearing is permanently maintained. This long-lasting lubrication enables significantly longer maintenance intervals, which is particularly advantageous on machines and systems with difficult-to-access environments. Relubrication in the recirculating ball is not necessary as the rolling elements are additionally greased with lithium saponified lubricant. Thanks to the precisely dosed lubrication of the rolling surfaces, the pollution-free system is also designed to be more environmentally friendly. Due to the low level of lubricant atomization, the MX ball bushings are also suitable for certain clean room applications, depending on the respective clean room class.

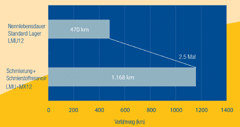

2,5f-oh higher rated life

2,5f-oh higher rated life

In the 24-hours practical test, it was possible to achieve a travel distance of 12 km with a standard LMU-470 ball bushing; with the MX version MX, 1168 km was just under 700 km more. This means that the nominal service life of the linear ball bearing with lubricant reservoir is higher by the 2,5 factor. Users benefit from the increased service life due to reduced operating and maintenance costs as well as less frequent assembly work. The MX system "forgives" thus also a forgotten lubrication.

The LMU standard bearings are coated with an anti-rust oil that does not replace lubrication. Factory lubrication is available in three versions:

- Type L (ET-100K by Kyodo Yushi) has a very high heat and oxidation resistance and is characterized by good adhesion and lower injection and discharge losses.

- Type G (LG2 from NSK Ltd.), which is also included in the MX reservoirs, provides very good anti-rust properties and has a comparatively low dust particle evolution cleanroom-suitable to a certain degree.

- Tap L (FGL from Lubriplate) is preferably recommended in machinery and equipment for processing or packaging of beverages, food and medicines.

With self-lubrication, the anti-rust oil used does not affect the lubrication. However, it is recommended to wash and dry the bearings before applying grease.

Seven at a stroke: plain bearings

The range of applications for the plain bearings product group is also broad: They are used, for example, in internal combustion engines, steam and water turbines, machine tools, in agricultural and domestic engineering, and entertainment electronics. Differentiated designs for every requirement are available on 27 pages of the catalog, including different flange shapes (rectangular, round and square flange) or bearing types already integrated in housings. This saves time for housing production and assembly; Due to the interchangeability, a new part is associated with comparatively low costs, since in some cases only the bushing has to be changed. Housing types are available as single, double or bearing designs. Individually suitable sockets with the required material and mechanical properties with different test results for the service life of sample applications are also included in the catalog. The range is divided into seven series:

- Bronze: Plain bearings made of lubricant-soaked porous bronze casting are well suited for high speeds and low loads with lubrication. They have a high wear resistance as well as heat and corrosion resistance. Due to the properties of the material, regular oil lubrication is recommended.

- Copper: These are bearings for maintenance-free operation with solid lubricant storage, embedded in high-strength brass. They are high-performance under medium load and at low speeds as well as highly abrasion-resistant in conditions that make it difficult to build up the lubricating film; this includes, for example, changing directions of rotation, vibrations or start / stop operation.

- Molding: The molybdenum disulfide type is spirally embedded in FC 250 (EN GJL 250) and also enables maintenance-free operation. As are the copper plain bearings Icing-Products high performance under medium load and at low speeds. The spirally embedded MoS2 solid lubricant results in a low coefficient of friction with changing directions of rotation and vibrations.

- Plastic (Types JZB, JZF, JZW): The bearings are made of polyoxymethylene (POM) and are oil-impregnated with fillers. Due to its high rigidity, low coefficient of friction and excellent dimensional stability, this plastic is used as a technical plastic, especially for precision parts. The bearings are characterized by maintenance-free operation, high-grade load as well as abrasion resistance, a low friction coefficient and excellent running properties. This helps prevent tread damage and squeaky noise.

- Plastic (Types TFZB, TFZF): Polytetrafluoroethylene (PTFE) plain bearings are equipped with solid lubricants and wear-resistant fillers. Also maintenance-free are other features: a low coefficient of friction at start and in high-speed, prevention of tread damage during operation and high abrasion resistance. These plastic plain bearings are especially recommended in conjunction with soft waves.

- Layer composite I: These are particularly thin, light and compact three-layer composite products for maintenance-free operation made of a steel back layer, sintered brass layer and PTFE sliding layer. They have a consistently low coefficient of friction under high load and at low speed. A high speed-load value can be achieved by operating with oil. Further advantages are the high chemical resistance and excellent thermal conductivity.

- Layer composite II: This version consists of a two-layer composite product made of the base material aluminum and a sliding layer fluoroplastic and has low wear and a low coefficient of friction at high speeds. With 1.6 x 10-7 mm3These sliding bearings have very good wear properties. The frictional resistance depends on the conditions of use, but may be above average. The BFLB type ideally exhibits its properties when the shaft material is soft, as in stainless steel, aluminum or brass. Due to the special product properties, the soft shaft material is hardly damaged.

3000 pages and back 1

Both the plain and rolling bearings as well as all other articles in the current, around 3000 pages strong main catalog all important details such as execution options, materials, possible surface treatments, prices and delivery times and component drawings are included. Together with the various other mechanical components required in addition to warehouse technology in the design process, procurement can be bundled. Fast information on the one hand and simplified supplier handling and streamlined work processes such as fewer goods receipt and invoice checks as well as inventory and cost bookings on the other hand can avoid unnecessary time expenditure. In addition, the subscription conditions are designed to be particularly user-oriented: Misumi delivers 1 even in individually configured execution starting from the quantity.

You might also be interested in...

Clamp ring | Adjusting ring and clamping coupling for shafts and axles

Misumi expands the production of configurable rotary shafts

2,5f-oh higher rated life

2,5f-oh higher rated life