MinebeaMitsumi | Precision as a drive

- Details

- Hits: 27068

MinebeaMitsumi has news to announce. The daughter Minebea Intec has with Manina Kettler new CFO. The daughter Myonic gets the title Exceptional delivery partner from Dentsply Sirona awarded. A new show trailer complements the trade fair marketing. Products can be presented to the customer flexibly and independent of location. We have compiled many other company reports for you below:

Content:

- Manina Kettler is the new CFO at Minebea Intec

- Minebea Myonic receives Exceptional Supplier 2022 Award

- Show trailer as a future-oriented tool for marketing

- MTCE celebrates its 30th company anniversary

- Bosch presents Global Supplier Award to MinebeaMitsumi Inc.

- New CSO at Minebea Intec

- Myonic: sustainability certificate for environmental protection

- Minebea Intec supports global vaccine production

Manina Kettler is the new CFO at Minebea Intec

11.01.2023 | Manina Kettler (40) has been Chief Financial Officer (CFO) at Minebea Intec since the beginning of the year. She is responsible for the areas of accounting, controlling treasury, IT and administration. Previously, this responsibility lay directly with Hidenori Shimosako, CEO of Minebea Intec.

11.01.2023 | Manina Kettler (40) has been Chief Financial Officer (CFO) at Minebea Intec since the beginning of the year. She is responsible for the areas of accounting, controlling treasury, IT and administration. Previously, this responsibility lay directly with Hidenori Shimosako, CEO of Minebea Intec.

Manina Kettler is a very good example of that employee development at the leading manufacturer of industrial weigh- and inspection technology is a top priority. In nine years she was able to develop from controller to CFO. In her new role, she will be in charge of budget allocation, reporting, contracting, insurance, IT strategy and cash flow planning.

Potential for more efficiency Ms. Kettler sees the process optimization and further digitization of the finance area in particular: "We have already had initial successes with the automated processing of invoices and travel expenses," says Manina Kettler. "One of our next projects in controlling will be to automatically map daily reports for our business partners."

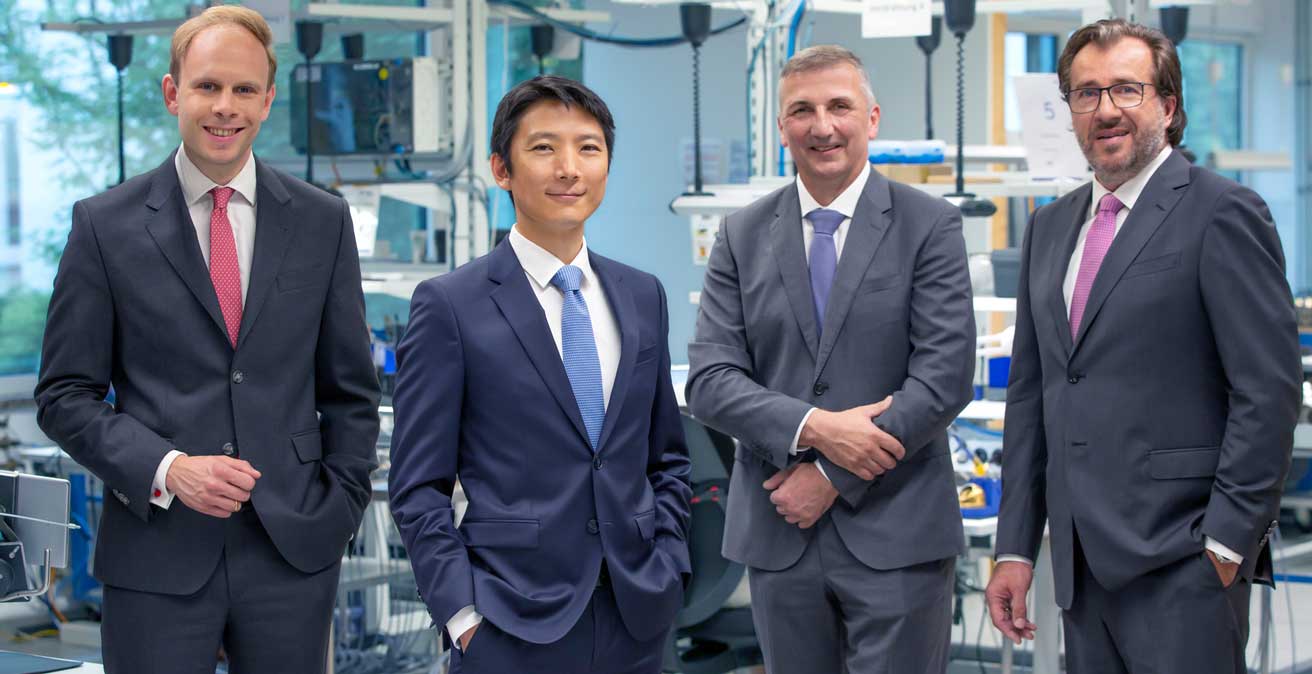

Together with Hidenori Shimosako (CEO), Nick Parsons (CSO), Dr. Karl Sommer (COO) and Dr. Axel Böttger (CTO), Manina Kettler will continue to expand Minebea Intec's business. "In her new position, she enriches the company with her great professional skills and her remarkable commitment," says Hidenori Shimosako. "I am convinced that they will make Minebea Intec even stronger."

The 40-year-old brings outstanding expertise in the field of finance with. After completing her dual business studies at VW, she held various positions as a controller in the service and management sector Food industry, before she started in Controlling for the Aachen site at Minebea Intec in 2013. In 2018 she took over the position of Director Accounting at the headquarters in Hamburg, and in 2019 Controlling was added. Ms. Kettler has been working as Deputy CFO since 2021. “I would like to interlink the individual departments even more and promote cooperation. For me, that is the key to success,” says Ms. Kettler.

Minebea Myonic receives Exceptional Supplier 2022 Award

09.12.2022 | Dentsply Sirona Inc. is the world's largest manufacturer of dental products and dental technology and one of the main customers of the MinebeaMitsumi subsidiary Myonic. In 2021, Dentsply Sirona introduced the "Supplier Awards Program for exceptional partners". The criteria for the award are based on the company's procurement goals: quality, sustainability, delivery performance, partnership, innovation, and diversity.

09.12.2022 | Dentsply Sirona Inc. is the world's largest manufacturer of dental products and dental technology and one of the main customers of the MinebeaMitsumi subsidiary Myonic. In 2021, Dentsply Sirona introduced the "Supplier Awards Program for exceptional partners". The criteria for the award are based on the company's procurement goals: quality, sustainability, delivery performance, partnership, innovation, and diversity.

From around 12.000 suppliers, only 70 companies were eligible for the title Exceptional delivery partner nominated, of which only one in each of 7 product groups was awarded for "Direct Material". myonic received the award in the "Rest of Spend" category, which mainly includes steels and products made of metal, such as bearings.

In addition to the excellent delivery and quality performance, the responsible director Todd Dunn the very good development partnership between the two companies in the foreground. The clear concept of becoming climate-neutral by 2030 deserves a special mention.

Show trailer as a future-oriented tool for marketing

21.04.2022/XNUMX/XNUMX | the Minebea Mitsumi Technology Center Europe GmbH wants in the future no longer just rely on the classic face-to-face trade fair. The new show trailer in the MinebeaMitsumi design puts products in the limelight, making them flexible and location-independent.

21.04.2022/XNUMX/XNUMX | the Minebea Mitsumi Technology Center Europe GmbH wants in the future no longer just rely on the classic face-to-face trade fair. The new show trailer in the MinebeaMitsumi design puts products in the limelight, making them flexible and location-independent.

Since 2020, the Corona Pandemic has shown that, especially in the B2B sector, there are creative alternatives to Trade fair marketing are needed. Even with the gradual return of face-to-face trade fairs, the circumstances and needs have changed permanently. According to that Trend paper of the Federal Association of Industry Communication (bvik) trade fairs will be more hybrid, more sustainable, smaller and more local in the future. The personal contacts and experiences continue to be a central added value in order to present oneself on site.

MinebeaMitsumi in Europe has been dealing with the new requirements and opportunities during the pandemic. The result is a trailer that has one Showroom on wheels presents. This offers a flexible product presentation without sacrificing personal contact. The special vehicle is intended primarily for the fast-growing automotive sector. Depending on the occasion, the trailer can be equipped individually with the respective products on the basis of flexible modules. Tablets and large displays also offer digital content in order to optimally tailor the content to the respective target group.

The trailer was equipped with the most important features of a fully-fledged exhibition stand. A small kitchen niche is available for customer events. The solution is also smart in terms of budget: "Compared to the trade fair presence, long-term planning can be significantly more cost-effective. The mobile trade fair stand can be brought directly to the customer and spontaneously optimized at any time," says Tobias Stemler, Business Development Manager at the Villingen-Schwenningen site. The presentation solution is also sustainable for the entire group of companies in Europe, because the trailer can be booked and shared with sister companies.

MTCE celebrates its 30th company anniversary

08.09.2021 | In 2021, the MinebeaMitsumi Technology Center Europe (MTCE) proudly looks back on 30 years of company history. The development center was founded in 1991 under the name PM DM. At the former location in Spaichingen, PM DM started developing HDD motors. MTCE has been based in the Auf Herdenen industrial area in Villingen since 2000. In 2019, the location was declared the European development headquarters of the parent company MinebeaMitsumi.

08.09.2021 | In 2021, the MinebeaMitsumi Technology Center Europe (MTCE) proudly looks back on 30 years of company history. The development center was founded in 1991 under the name PM DM. At the former location in Spaichingen, PM DM started developing HDD motors. MTCE has been based in the Auf Herdenen industrial area in Villingen since 2000. In 2019, the location was declared the European development headquarters of the parent company MinebeaMitsumi.

In the meantime they are just developing here 460 employees neben Engines and Drive Technology also numerous other products such as LED backlights and sensors. The areas of application for the products developed in Villingen are as diverse as they are. They are used, for example, in the automotive industry, especially in the field of Electromobility, used. In addition, the business areas are growing Power Tools, Robotic and automated logistics.

Koco Motion News: System house for intelligent motor technology

Koco Motion News: System house for intelligent motor technology

Managing Director and European Head of the international group Jorg Hoffman draws a positive conclusion on the occasion of the company's 30th anniversary: “In the last 30 years we have made many right and courageous decisions and have thus achieved a unique position in the MinebeaMitsumi Group. In 1991 nobody would have thought that we would become the Group's European development headquarters in Villingen-Schwenningen. Or that our street will be renamed Minebea Way. "

Milestones from MinebeaMitsumi Europe

One of the most important milestones MinebeaMitsumi took part in the company's history in 2010. The MTCE developed this year beyond the function of a pure development center. For the first time in Bratislava, Slovakia, the company's own BLDC motors were produced and successfully launched on the market. Today Minebea mainly produces in the largest and most important European production plant in Košice, also Slovakia, which opened in 2018.

The year 2019 brought with the Takeover of the U-Shin Groups probably the biggest challenge so far. As a result of the takeover, the MTCE became the headquarters for currently 22 European production and development locations. Within the new tasks, the ongoing corona crisis naturally also presented MTCE with new challenges. But even in this phase, the success story of MinebeaMitsumi Technology Center Europe could be continued.

Faulhaber will start with a new management structure from January 2022

Faulhaber will start with a new management structure from January 2022

“While numerous companies had to struggle with extreme downturns, especially in the automotive sector, MTCE was able to continue bring new products to market. Our team is doing really great here, ”says Jörg Hoffmann. There is only one downer on the company's anniversary: “Unfortunately, there was no big celebration with our employees this year. But we would like to do that as soon as circumstances permit. "

Bosch presents Global Supplier Award to MinebeaMitsumi Inc.

25.08.2021/5/XNUMX | MinebeaMitsumi Inc. has received the "Bosch Global Supplier Award" from Bosch for the XNUMXth time. This makes the company one of the world's best suppliers to the technology leader and service provider. With the award in the category Raw material and components Bosch recognized the achievements of the “Miniature Ball Bearings” division on a global level.

25.08.2021/5/XNUMX | MinebeaMitsumi Inc. has received the "Bosch Global Supplier Award" from Bosch for the XNUMXth time. This makes the company one of the world's best suppliers to the technology leader and service provider. With the award in the category Raw material and components Bosch recognized the achievements of the “Miniature Ball Bearings” division on a global level.

46 suppliers from 16 countries awarded Bosch from around 23.000 suppliers. For the 17th time, the Bosch Group is honoring above-average performance in the manufacture and delivery of raw materials, products or services, especially in terms of quality, costs, innovations and logistics. “The corona pandemic has shown how important a functioning supplier network is for global supply chains. The winners of the Bosch Global Supplier Award played an important part in this, ”said Dr. Arne Flemming, Head of Supply Chain Management at Bosch.

“We are proud that our high standards have once again been recognized by Bosch. Even during the corona pandemic, we were able to meet the steadily increasing demands on suppliers in terms of quality, delivery reliability and competitiveness and supplement them with a sustainable company focus. We look forward to the trusting and successful cooperation with Bosch, ”said above Thomas Prigge, Head of Ball Bearing & Mechanical Components Division, Europe.

New CSO at Minebea Intec

31.08.2021 | Peter Steiner As the new Chief Sales Officer (CSO), he will drive business in the partner regions worldwide in addition to the sales development in the core markets. With him, the C-Level under CEO Hidenori Shimosako is complete.

Peter Steiner succeeds Frank Wieland and is looking forward to a varied role with the leader Manufacturer of weighing and inspection technology: "Minebea Intec combines the history of a German engineering company with the internationality and reach of a world market leader - that is a rare and extraordinarily attractive combination," says Mr. Steiner, looking forward to the multifaceted task. "The management team, which I was able to get to know in detail before starting at Minebea Intec, maintains a professional, open and very appreciative relationship within and outside the team."

Michael Koch GmbH: News from Ubstadt-Weiher

Michael Koch GmbH: News from Ubstadt-Weiher

Peter Steiner was previously responsible for the sales and service organization of one international packaging machine manufacturer directed. Together with Dr. Karl Sommer (COO), Dr. Axel Böttger (CTO) and CEO Hidenori Shimosako would now like to introduce the CSO to new perspectives in the company, “I hope that, as the newest member of the management team, I can set a lot of impulses with my broad sales experience.

Myonic: sustainability certificate for environmental protection

06.04.2021 | For years, Myonic, a MinebeaMitsumi Group company, has been committed to the consistent recycling of raw materials and waste streams for global resource and environmental protection. The specialist in precision bearings maintains an environmental management system in accordance with the internationally recognized standard ISO 14001..

06.04.2021 | For years, Myonic, a MinebeaMitsumi Group company, has been committed to the consistent recycling of raw materials and waste streams for global resource and environmental protection. The specialist in precision bearings maintains an environmental management system in accordance with the internationally recognized standard ISO 14001..

Now the recycling service provider Remondis Myonic has a particularly good one with the sustainability certificate Resource economy and one demonstrable Climate protection contribution certified. In doing so, Remondis has considered the commitment that supports its own positioning in environmental protection, such as the return of raw materials into the product cycle, reduction of primary raw material consumption and greenhouse emissions through thermal and material waste recycling as well as the production of alternative energies and innovative recycling products.

Over the past few years, Myonic has been adding new ones regularly Measures implemented: For example, plastic filling material was replaced by recyclable corrugated cardboard in shipping, returnable packaging was used instead of one-way packaging and waste was consistently separated. By extending the use of operating materials such as oils, lubricants or cleaning media, waste has also been reduced.

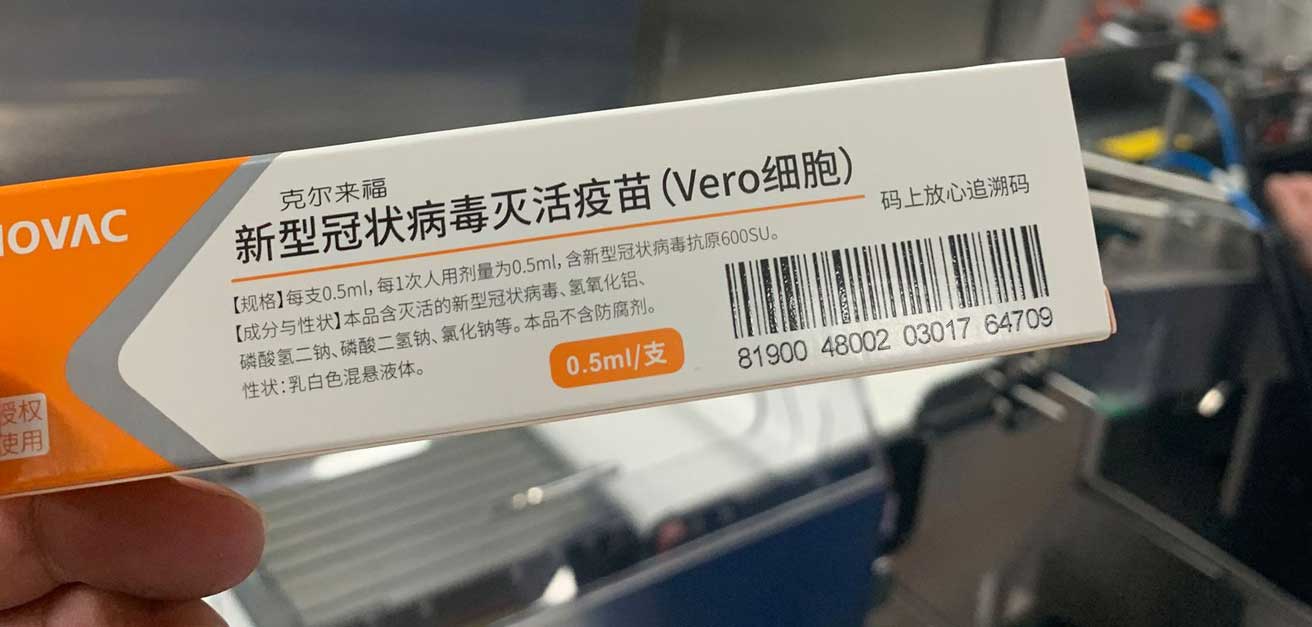

Minebea Intec supports global vaccine production

10.03.2021/XNUMX/XNUMX | Since that Coronavirus has erupted, the world economy is upside down. Structures that were once fixed, such as import, export and supply chains, have proven to be fragile constructs since the outbreak of the coronavirus. The manufacturing industry reports deep cuts worldwide. Nevertheless, in these times individual manufacturers such as Minebea Intec, a member of the MinebeaMitsumi Group, are proving top performance, especially where it is most important in this pandemic time.

Igus clears the way for innovative plastic recycling

Igus clears the way for innovative plastic recycling

Corporations around the world are working flat out on the development and production of reliable vaccines. The global manufacturer of industrial Weighing and Inspection Technologies Minebea Intec supports you in this. The provider, based in Hamburg, manufactures special products that are precisely tailored to the needs in these areas. Machines and systems weigh mixing containers and check packaging steps. All of this happens under the strictest hygienic conditions. Minebea Intec's technologies enable standardized, precise processes along the entire production line.

Highly accurate and reproducible processes are essential in the Development and production of vaccines. Minebea Intec offers research, engineering and production for special technologies and hygienic designs according to worldwide standards. For example, load cells are installed under bioreactors and connected to evaluation electronics. In this way, they ensure the best possible mix of raw vaccines and other substances. Other, dynamic weighing solutions ensure the correct filling quantity of the vaccination doses.

Archive for further company news

- MinebeaMitsumi donates 17.000 protective masks across Europe

- MinebeaMitsumi takes over drive specialist Mast

- Experience Center of Minebea Intec opened in Thailand

- PM DM becomes MinebeaMitsumi Technology Center Europe

- MinebeaMitsumi opens new plant in Košice, Slovakia

MinebeaMitsumi donates 17.000 protective masks across Europe

03.04.2020/XNUMX/XNUMX | Numerous care facilities are desperately looking for the necessary equipment for their employees in the corona crisis. In large parts of Europe, the stock of protective clothing and respiratory masks is dwindling. Those responsible in most countries are currently generally advising to wear protective masks in public, even if they are only makeshift protective masks. MinebeaMitsumi President Yoshihisa Kainuma and European boss Jorg Hoffman initiated the distribution of a total of 17.000 N95 protective masks around the 17 European locations.

Solidworks 2023 | CAD software by and for users

Solidworks 2023 | CAD software by and for users

"In the current situation, we feel it is our responsibility to protect not only our own employees, but also the local communities and associations and thus the respective regional economy as well as possible," said Jörg Hoffmann. "Right now it is important that we use our strong international network and act in solidarity." The corporate headquarters in Tokyo provided ever 1000 protective masks as a donation available for the 17 European daughters. Each company decided which of the regional facilities was in greatest need, and numerous hospitals and care facilities were deeply grateful for the urgently needed donations.

Only coronavirus infected patients

The Minebea Mitsumi Technology Center Europe GmbH in Villingen-Schwenningen donated the 1000 protective masks to the Black Forest Baar Clinic at the Donaueschingen location, where patients who are now only infected with the corona virus are being cared for. The masks were handed over on Wednesday, April 01, 2020 by Managing Director Jörg Hoffmann, Jessica Krebs, Head of Best Practice Academy, Tomoyuki Saito, COO and Roman Klein, Head of Communications Minebea Mitsumi Europe.

We are very happy about the donation ”, so dr Hinrich Bremer, Head of Pneumology at the Schwarzwald-Baar Clinic. “The masks are a real help for our staff. They contribute to the protection of our employees and thus to occupational safety. "

In the corporate headquarters in Tokyo and in the European headquarters in Villingen-Schwenningen were early Covid-19 Countermeasure Teams convened to work together under high pressure to support the subsidiaries with information, protective masks and measures to contain the spread of the virus. “The common goal is to make our workplace one of the safest places,” explains Jörg Hoffmann.

MinebeaMitsumi takes over drive specialist Mast

16.01.2020/XNUMX/XNUMX | The takeover of Mast plastics GmbH & Co. KG through MinebeaMitsumi took place in the course of the planned corporate succession. The aim is to expand the product portfolio to include the development and manufacture of driving elements be strengthened and expanded. Peter and Ulrich Mast agree that the MinebeaMitsumi Technology Center is a strong and dynamic partner for the future direction. The two managing directors remain in their office. By securing the existing jobs, you have achieved an important goal in succession planning.

16.01.2020/XNUMX/XNUMX | The takeover of Mast plastics GmbH & Co. KG through MinebeaMitsumi took place in the course of the planned corporate succession. The aim is to expand the product portfolio to include the development and manufacture of driving elements be strengthened and expanded. Peter and Ulrich Mast agree that the MinebeaMitsumi Technology Center is a strong and dynamic partner for the future direction. The two managing directors remain in their office. By securing the existing jobs, you have achieved an important goal in succession planning.

The location in Bad Waldsee was founded in 1960 by Franz Mast. As a manufacturer of industrial precision plastic parts, the company quickly established itself in the industry. In 1992 Peter and Ulrich Mast took over the company and in almost 30 years of joint management, the brothers developed the company into a leading supplier of tool-bound gear and drive elements made of plastic.

As part of Minebea, the site is to be a European competence center for tool-bound precision plastic parts. Operations continue as usual and MTCE can look forward to 130 new colleagues.

"With the acquisition, the international group of companies Minebea Mitsumi is expanding its vertical production structures in Europe and creating new European synergies", so Rudolph Neuman, Minebea Mitsumi Integration Officer. He is now working very closely and successfully with the mast management team. He currently has a dual role and is involved in both companies. This year, Rudolf Neumann will be part of Mast's management and will completely relocate his office to Bad Waldsee.

Experience Center of Minebea Intec opened in Thailand

06.12.2019 | With the new Experience Center (EC) in Bangkok, Thailand, Minebea Intec offers 100% local support and service in Southeast Asia. Visitors have the opportunity to get a live impression of the complete product portfolio in the brand new showroom, to carry out personal training and product tests and to receive fast and professional technical support.

06.12.2019 | With the new Experience Center (EC) in Bangkok, Thailand, Minebea Intec offers 100% local support and service in Southeast Asia. Visitors have the opportunity to get a live impression of the complete product portfolio in the brand new showroom, to carry out personal training and product tests and to receive fast and professional technical support.

The Minebea Intec Experience Center is the latest addition to the MinebeaMitsumi production facility on site. With this center, Minebea Intec is moving closer together with its parent company, which is the location with its more than 25.000 employees has been operating successfully since 1985. The facility serves primarily as a support, engineering and Training center, and above all should improve the proximity to local customers and partners in Southeast Asia.

PM DM becomes MinebeaMitsumi Technology Center Europe

27.09.2019/XNUMX/XNUMX | Originally as a pure development center for HDD motors was founded, the company PM DM has now established itself as the linchpin for engine development in the international parent company Minebea Mitsumi. From October 1st, the company name will also be adapted to its central position in the group of companies: PM DM GmbH will become Minebea Mitsumi Technology Center Europe GmbH.

27.09.2019/XNUMX/XNUMX | Originally as a pure development center for HDD motors was founded, the company PM DM has now established itself as the linchpin for engine development in the international parent company Minebea Mitsumi. From October 1st, the company name will also be adapted to its central position in the group of companies: PM DM GmbH will become Minebea Mitsumi Technology Center Europe GmbH.

The engine development center Precision Motors German Minebea (PM DM) was founded in 1991 and has been based in Villingen-Schwenningen in the Black Forest since 2000. The location has grown rapidly and steadily - today over 400 employees, mostly developers and engineers, work on the Minebea route.

"With the change of name, the Technology Center Europe also takes on new areas of responsibility", explains the managing director and Minebea Mitsumi Europe boss Jorg Hoffman. "In addition to our current activities, we will act as a central development center for various new products and technologies from our parent company in the future."

The goal is through this even faster and more effectively Bringing innovations to market together with European customers. In future, the development portfolio in Villingen will no longer be limited to the development of drive technologies, but will also include new areas such as LED backlights and sensors.

The Tech Center will be used for a total of 17 other European production and development locations Development headquarters. Jörg Hoffmann is confident about the great challenge: “We have worked hard for our position and function in the group, the change of name is the next step in our growth strategy. We will bring the European locations under one roof as best we can. ”PM DM will not, however, completely disappear from the scene. As a brand name, customers can still find the familiar lettering on the products.

MinebeaMitsumi opens new manufacturing plant in Košice

18.06.2018 | 100 million euros Minebea Mitsumi, headquartered in Tokyo, is investing in a new production plant in Slovakia by 2022, with the Japanese company particularly focusing on the automotive sector. The opening of the new plant took place on June 15, 2018. Around 200 guests from business and industry were invited.

The starting shot for the major project was given on December 2nd, 2016 in the course of a press conference in the town hall of Košice, the groundbreaking ceremony took place on May 5th, 2017. With the new plant in Eastern Slovakia, around 1100 jobs. With several universities and a technical university on site, Minebea Mitsumi primarily relies on Slovak specialists at this location, because the development and optimization of production are also to be partially located on site and coordinated by the subsidiary and engine development center PM DM in Villingen-Schwenningen.

In the future, a total of around 2000 new jobs develop. When asked about the reasons for choosing a location, the focus is on using synergies with the European subsidiaries, shortened transport routes for the European market, minimizing exchange rate fluctuations and, of course, customer proximity, especially in the automotive industry.

The opening event took place on June 15, 2018. With an impressive supporting program on the company premises, the start of production was celebrated with around 200 guests from all over Europe, the USA and Japan. "The opening of this production plant represents a milestone in the company's history for our European subsidiaries and the entire group." Jorg Hoffman, General Manager of Regional Affairs for Europe and CEO of PM DM GmbH.

The opening event took place on June 15, 2018. With an impressive supporting program on the company premises, the start of production was celebrated with around 200 guests from all over Europe, the USA and Japan. "The opening of this production plant represents a milestone in the company's history for our European subsidiaries and the entire group." Jorg Hoffman, General Manager of Regional Affairs for Europe and CEO of PM DM GmbH.

"We manufacture drive systems at the Slovakian location, BLDC motors, Sensors and components, mainly for the automotive industry, in large quantities. But new technological developments will also find their way into production in Košice. With the opening, a dream has come true for us. " Yoshihisa Kainuma, Minebea Mitsumi President and Chief Executive Officer, thanked the Slovak government and everyone involved for their support. Peter Pellegrini, Prime Minister of Slovakia, emphasized the positive effects that the new plant will have on the quality of life in Košice.

MinebeaMitsumi is a global company and employs around 100.000 people at 63 locations in 27 countries worldwide. When Minebea was founded in Tokyo in 1951, the focus was initially on miniatureBall bearings. In 2017, the MinebeaMitsumi Group emerged from the merger with Mitsumi Electric. In Europe, the group includes the following companies: MinebeaMitsumi Technology Center Europe, NMB Minebea, Minebea Intec, Myonic, Paradox Engineering, Cerobear, Mast Kunststoffe. In a strong network they offer a wide variety of key technologies such as for Automotive, Aerospace, Manufacturing, Medical Technology and healthcare.

You might also be interested in...

Artificial Intelligence | trends and developments

smart city | Mega buildings, infrastructure, technologies

Load cell, weighing electronics, industrial scales from Minebea Intec

Integrated wheel hub motor for driverless transport systems

BLDC motor for smooth running and long runtime

Open source mesh network for the smart city

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.