cover story

cover story

Ready-made sauces are practical. But also a challenge for the bottlers and their machines in the food technology, In addition to bottling, mixing the many ingredients in the production process also plays a key role. The possibilities and variations are almost unlimited. Dosed, mixed and bottled in a project of Viscotec various ingredients with different viscosities or lumpy materials.

These can be, for example, liquid sauces and spice mixtures with mushrooms, onion pieces, cucumber slices or candied fruits for catering companies. The filling quantity varies between 125 ml and 500 ml. Thanks to the proven technology, pieces up to a size of 25 mm can be filled.

In order to make the high-quality products available to the end user in high quality and without damage, a gentle filling technology is required. A special product displacement process, which modern packaging machine manufacturers take advantage of, enables sensitive products to be packed in tubular bags with little air. Due to the continuous operation of the vertical forming, filling and closing machines, a continuous supply of packaging material can be combined with endless or continuously metering filling operations.

In order to make the high-quality products available to the end user in high quality and without damage, a gentle filling technology is required. A special product displacement process, which modern packaging machine manufacturers take advantage of, enables sensitive products to be packed in tubular bags with little air. Due to the continuous operation of the vertical forming, filling and closing machines, a continuous supply of packaging material can be combined with endless or continuously metering filling operations.

Advantage of continuously operating machines

A low reject rate is just as important as high throughput times and continuous performance. Not only for manufacturers who want to increase their productivity through maximum utilization of their packaging lines. Particular attention is paid to the process of bag filling. In order to achieve a high production frequency, the individual process steps must be concatenated as short and fluidly as possible.

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

A precise and elaborate fine-tuning of the individual components is absolutely necessary for this. Especially with smaller packaging sizes such as 10 ml, the interruptions that are necessary for the tube feed and the sealing of the tube take up valuable cycle time. Here you can clearly see the advantage of continuous flow wrapper machines: Compared to intermittent machines, the filling process and the sealing process can not be switched one after the other, but at the same time.

Continuous filling with endless piston technology

The dosing pumps with eccentric screw technology from Viscotec are perfectly tailored to this continuous mode of operation. With the endless piston technology from the dosing technology specialist, the products belong to the group of rotating displacement pumps. The way it works is comparable to an endless piston that conveys the product from the suction side to the pressure side and thereby builds up a pressure difference. The core of every application is a volumetrically conveying metering pump. The interaction of an eccentrically moving rotor and stator results in a delivery and metering characteristic that corresponds to that of an endlessly moving piston.

The dosing pumps with eccentric screw technology from Viscotec are perfectly tailored to this continuous mode of operation. With the endless piston technology from the dosing technology specialist, the products belong to the group of rotating displacement pumps. The way it works is comparable to an endless piston that conveys the product from the suction side to the pressure side and thereby builds up a pressure difference. The core of every application is a volumetrically conveying metering pump. The interaction of an eccentrically moving rotor and stator results in a delivery and metering characteristic that corresponds to that of an endlessly moving piston.

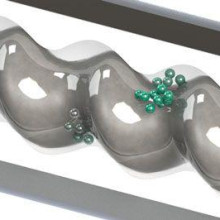

This endless piston principle is particularly suitable for the conveying and filling of abrasive and solids-laden, ie lumpy media. A key benefit of this technology lies in the resulting delivery chamber, whose volume remains absolutely constant during the course of the movement. This feature makes it possible to fill a wide range of sauces - high-precision, absolutely repeatable and gentle. From smooth sauces to lumpy component sauces, everything is just as much part of it as from small sample packs with 5 ml to large packs with several liters.

Carefully fill without damaging dosing materials

The solids are conveyed particularly gently in their carrier medium through the chambers between rotor (stainless steel) and stator (elastomer). The shape, color and consistency of the solids are not affected. A uniform particle distribution is guaranteed and the desired product properties are completely preserved. Even large pieces up to a size of 25 mm with excellent particle integrity can be dosed with a repeat accuracy of over 99%.

The solids are conveyed particularly gently in their carrier medium through the chambers between rotor (stainless steel) and stator (elastomer). The shape, color and consistency of the solids are not affected. A uniform particle distribution is guaranteed and the desired product properties are completely preserved. Even large pieces up to a size of 25 mm with excellent particle integrity can be dosed with a repeat accuracy of over 99%.

For precise, low-volume filling of viscous, abrasive or solids-laden products such as the hot chilli sauce, conventional filling technologies such as piston or peristaltic pumps reach their limits. For these types of pumps, solids-containing or abrasive products are particularly critical: Often, mechanical damage to the moving parts occurs here.

Especially for these applications, filling pumps in the endless piston principle are very well suited. Advantages of this technology include, for example, a variable and, if required, customer-specific material selection of the dosing components, the particularly low-shear conveyance and a laminar flow within the rotor-stator design.

Dispenser in Hygienic Design

Liquid and pasty products place very high demands on hygiene in the packaging process. Due to their special design, the dosing pumps of the supplier meet all requirements. The pump housing designed in accordance with the EHEDG guidelines is dead-space optimized to avoid any product deposits. From a design point of view, attention was paid to easy and quick disassembly. This facilitates not only automatic cleaning but also manual cleaning after disassembly. To serve the high quality and hygiene regulations of the customers.

You might also be interested in...

Hygienic dosing systems for precise spreads

Artificial heart valve from the 3D printer

Nord Antriebstechnik solutions for food technology

Microdosing of adhesive for the production of fiber optic cables