There are only a few all-electric ones so far Tool changer on the market, mostly pneumatic ones are used here. The electric ones already on offer only cover the area of small mechatronic ones grab away. Since the trend here too is 'exchange Pneumatics due to Electrics' does not stop at further development Gimatic electrical Tool changer included in the program. this as well hand-operated novelties and a case study from the 3D concrete printing can be found below:

Contents

- Single-actuated manual changer for Industry 4.0

- Electric tool changer as an alternative to the pneumatic one

Single-actuated manual changer for Industry 4.0

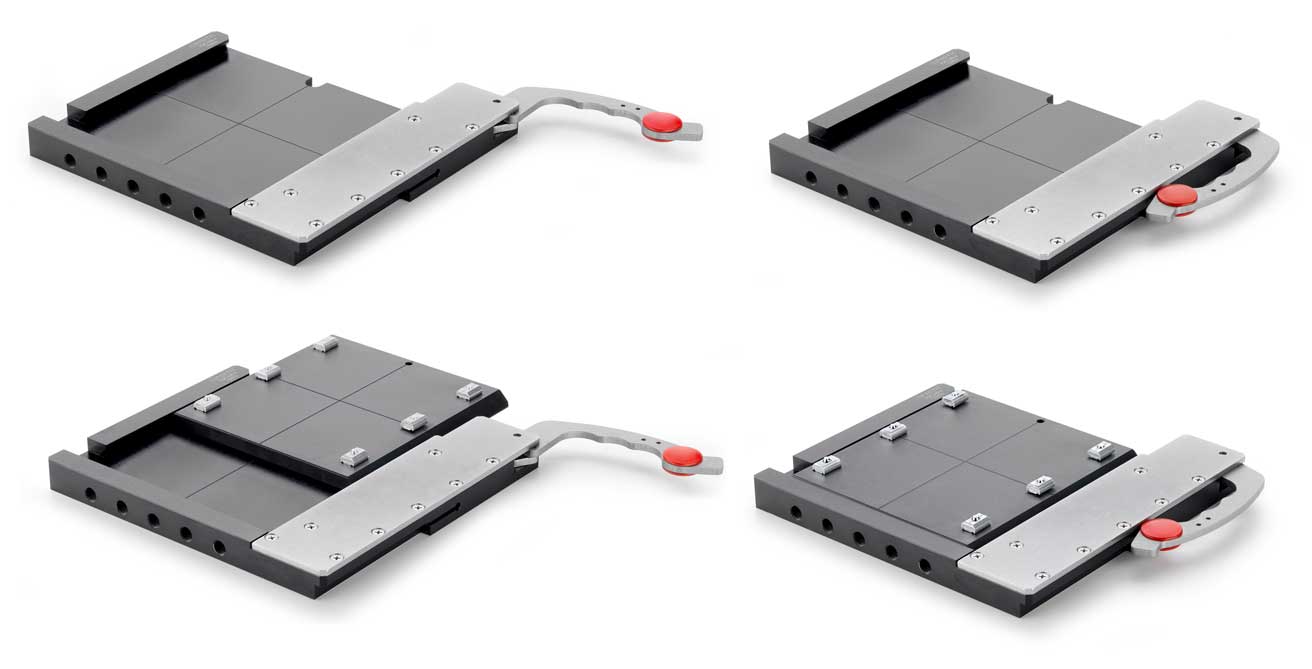

October 03.12.2019, XNUMX | Gimatic has its simple Hand change system SQ further developed. This makes it suitable for tool changes in Industry 4.0 Robotic. The base plate on the robot side is now available in a version with a secure lock that is queried by sensors.

The manual changer is based on simple base plates measuring 100 x 100, 150 x 150 and 250 x 250 mm. the robot-side base plate is compatible with all existing base plates on the gripper side. An integrated wedge mechanism ensures that the plate on the gripper side is loaded over the entire surface and is thus fixed in the correct position. angle error at robot gripper are thus excluded. The square quick coupler can be operated with just one movement.

Soft grippers load the Innolas wafer sorting machine

Soft grippers load the Innolas wafer sorting machine

The lock is form-fitting and is secured with a Sensor requested. The sensor query is used to detect that the gripper system is securely seated - an important feature for Industry 4.0 applications.

Electric tool changer as an alternative to the pneumatic one

09.06.2016 | The all-electric tool changer from Type EQC75 complements the mechatronic gripper program from Gimatic. This means that even larger grippers can now be operated fully electrically. The tool changer fits all mechatronic grippers and is suitable for tool changing applications with payloads of up to 10 kg. Applications can be found in all handling and linearrobotn that work mechatronically and dispense entirely with pneumatics.

09.06.2016 | The all-electric tool changer from Type EQC75 complements the mechatronic gripper program from Gimatic. This means that even larger grippers can now be operated fully electrically. The tool changer fits all mechatronic grippers and is suitable for tool changing applications with payloads of up to 10 kg. Applications can be found in all handling and linearrobotn that work mechatronically and dispense entirely with pneumatics.

With its compact dimensions of 75 x 145 x 60 mm, the all-electric tool changer weighs only 1,1 kg. For example, it fits into the tight installation spaces of many small robots in the weight class up to 5 kg.

The EQC75 is controlled via the 24 VI/O circuit. Programming or additional control is not necessary. Maximum torque is 150 Nm, maximum pulling force is 2000 N and maximum payload is 10 kg. Switching between electrics and pneumatics is easy because the changing system has four air connections. It was also equipped with integrated sensors for position detection. The signal is output via the maincable. Using the 24-pin connector and the 8-pin cable, the signals from the sensors and the Power Supply transfer. Thanks to an associated, compatible adapter that is certified according to ISO 9409-1, third-party products can also be connected later.

Tool changer in the 3D concrete printer for the construction site of the future

15.08.2016/XNUMX/XNUMX | What if: When building your own home you could create individual concrete parts according to your wishes and with all this also CO2 would reduce? The start-up knows how to do this Print Stones: The mobile 3D printer processes individual concrete parts on site at the construction site. A well-known from the industrial automation provides the necessary flexibility Tool changer from Gimatic.

Wear-free spindle nut made of plastic for heavy loads

Wear-free spindle nut made of plastic for heavy loads

The Viennese start-up Print Stones has been dealing with automation in construction since 2017. The focus is on the development of a 3D Printprocess for the automated production of concrete objects suitable for construction sites, which draws attention to itself with two unusual features: It is mobile and prints concrete and other cementitious materials that are used on construction sites. Conventional formwork elements are therefore a thing of the past.

dr Herwig Hengl is the founder of the spin-off of the Vienna University of Technology. He first came into contact with additive manufacturing about five years ago as an employee at the Institute for Mechanics of Materials and Structures: "We came up with this idea when we were developing a simulation tool that can be used to analyze stress and deformation of stressed components.

dr Herwig Hengl is the founder of the spin-off of the Vienna University of Technology. He first came into contact with additive manufacturing about five years ago as an employee at the Institute for Mechanics of Materials and Structures: "We came up with this idea when we were developing a simulation tool that can be used to analyze stress and deformation of stressed components.

To verify the simulation results, the initially virtual components had to be rebuilt and loaded. Since this is a very costly and time-consuming process, we looked for a way to automatically produce the components directly from 3D models,” the young entrepreneur recalls. Ideally, of course, this should take place directly at the final place of use: on the construction site of the future.

The Printstones founders were able to compete with around 200 other start-ups with their business idea in a selection process by the university incubator Inits push through. The business model was then validated using qualitative and quantitative experiments and the development of the “Printstones X1” could start.

Potential application in own thing

The Gimatic Vertrieb GmbH supplies the tool changing system for the 3D printer. The people of Heching have always been open-minded unusual and not immediately mass-oriented Applications been.

The Gimatic Vertrieb GmbH supplies the tool changing system for the 3D printer. The people of Heching have always been open-minded unusual and not immediately mass-oriented Applications been.

In this application, Managing Director sees John Lörcher even an application on our own behalf: "3D printing is very much on the rise and one reads more and more about new developments for the construction industry. I think the idea of printing building blocks is great - even if printing bricks is not yet possible due to the regulations.

But with our current one New building in Hechingen we could very well use such a printer for the many surfaces on the paving stones." Johannes Lörcher assumes that such applications in the non-industrial area will increase with the further development of the Cobots will still increase significantly.

One cubic meter of concrete with free geometry

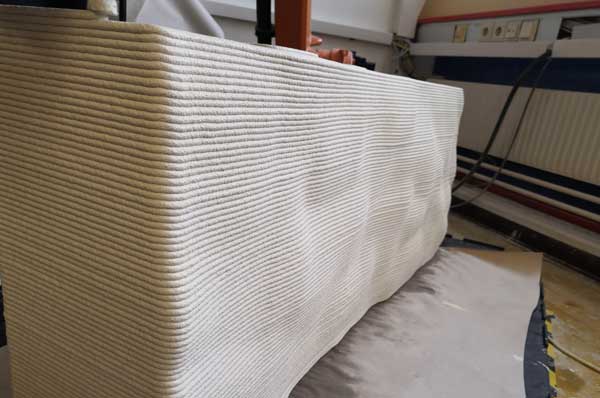

The Printstone's X1 is an early prototype of a mobile construction site 3D printer. It can currently be used to print concrete elements up to a size of around 1 m3. Of the Robot can be used both outside and inside. It eliminates the need for conventional formwork by precisely placing and solidifying defined volumes of material in successive layers through a computer-controlled positioning process.

The Printstone's X1 is an early prototype of a mobile construction site 3D printer. It can currently be used to print concrete elements up to a size of around 1 m3. Of the Robot can be used both outside and inside. It eliminates the need for conventional formwork by precisely placing and solidifying defined volumes of material in successive layers through a computer-controlled positioning process.

The 3D printing process consists of two general steps: the 3D modeling and the component printing. Various methods for generating robot trajectories are implemented in path generation. In general, each layer consists of an outline and a fill pattern, which can be implemented as honeycomb structures or space-filling curves.

The material preparation runs fully automatically via an upstream mini concrete plant. The recipe can be varied during the printing process, for example in order to print heavily loaded zones with higher-strength material. With this technology, components can be printed in variable forms from a batch size of 1.

Characteristics of a tool changer with a key role

"Gimatic recognized the potential of Printstones early on and supported us with a suitable offer,” says the founder. The Printstones X1 currently has the 3D printing nozzle via another tool for measuring the background on which the print is made. The tool changer is therefore an important part of the system and necessary for the fully automatic change between the tools.

"Gimatic recognized the potential of Printstones early on and supported us with a suitable offer,” says the founder. The Printstones X1 currently has the 3D printing nozzle via another tool for measuring the background on which the print is made. The tool changer is therefore an important part of the system and necessary for the fully automatic change between the tools.

"This application shows once again how practical it is to have a contact person on site," recalls Johannes Lörcher. "Our Technical Advisor Lars Janser from our branch in Graz visited the start-up in Vienna after an initial contact from Printstones, advised and convinced the young entrepreneurs. Our tool changer made it easy for him: the main arguments were that it is very compact and offers super-simple control".

The all-electric tool changer type EQC75 is suitable for changing applications with Payloads of up to 10 kg. It is mainly used in handling and linear robots for industry that work mechatronically and dispense entirely with pneumatics. With its compact dimensions of 75 x 145 x 60 mm, it weighs only 1,1 kg.

In industry, for example, it fits into the tight installation spaces of many small robots in the weight class up to 5 kg. The EQC75 is controlled via the proven 24 VI/O circuit. Programming or additional control is not necessary. being maximum torque is 150 Nm, the maximum pulling force 2000 N and the maximum payload 10 kg.

Robotic gripper, EOAT, gripper kits for Cobot and IR

Robotic gripper, EOAT, gripper kits for Cobot and IR

It can be used for users who do not want to switch completely easy to switch between electrics and pneumatics, because the changing system has four air connections. It was also equipped with integrated sensors for position detection. The signal is output via the main cable. Using the 24-pin Plug and the 8-pole cable, the signals from the sensors and the power supply can be transmitted. Thanks to an associated, compatible adapter that is certified according to ISO 9409-1, third-party products can also be connected. Subsequent conversion is also possible without any problems.

3D printing reduces CO2emissions

“Concrete is the second most used material by man after water, but at a high cost. Cement making is for about eight percent of global CO2 emissions responsible," says Dr. Hengel to consider. The proportion of CO2-Emissions from aviation are comparatively low here at 2,6 percent. “Therefore, our goal should be to reduce cement consumption wherever possible. Concrete 3D printing offers the possibility of omitting weakly stressed zones of a component and thus saving material.”

“Concrete is the second most used material by man after water, but at a high cost. Cement making is for about eight percent of global CO2 emissions responsible," says Dr. Hengel to consider. The proportion of CO2-Emissions from aviation are comparatively low here at 2,6 percent. “Therefore, our goal should be to reduce cement consumption wherever possible. Concrete 3D printing offers the possibility of omitting weakly stressed zones of a component and thus saving material.”

The system is as Multi tool device designed. So the concrete 3D printing nozzle is one of many possible tools. Further tools are to be developed in joint development projects with future users and customers.

“We are primarily active in research and development and try to involve future customers as much as possible. We work exclusively with local partners such as architectural offices, industrial designers, builders and contractors. With the latter group we still have something to do pioneering work because the construction industry, which accounts for around seven percent of the world market, invests far less in research and development than the average for other industries," points out Herwig Hengl.

Vision and possibilities for 3D concrete printing

“Our vision, or should I say Mission, is the Automation and optimization of construction processes. We would like to reduce monotonous activities on the construction site with our technology and relieve construction workers. A good example is this Laying paving stones. Nobody enjoys laying stones on their knees in a bent position eight hours a day. With the mobile 3D printer, these blocks can be printed directly onto the top base course of the road structure – laying them is then no longer necessary,” Herwig Hengl points out one of the possibilities.

“Our vision, or should I say Mission, is the Automation and optimization of construction processes. We would like to reduce monotonous activities on the construction site with our technology and relieve construction workers. A good example is this Laying paving stones. Nobody enjoys laying stones on their knees in a bent position eight hours a day. With the mobile 3D printer, these blocks can be printed directly onto the top base course of the road structure – laying them is then no longer necessary,” Herwig Hengl points out one of the possibilities.

Printstones is currently working as an executive company on pilot projects in the construction sector. The start-up would like to switch to the system provider have accomplished. The future goal is to provide hardware, software and, in particular, building materials.

In the cooperation, the Viennese also see a future application for the grippers from Gimatic in theirs construction site robots. For example, you can imagine using them to insert reinforcement elements or other built-in components. At Gimatic, the application is one of a number of other exciting applications. And so, in addition to picking strawberries or collecting snails in the agricultural industry, in the future concrete parts will also be gripped safely, reliably and efficiently as a contrasting program.

You might also be interested in...

Robot Gripper | Automated little hands

These vacuum grippers handle everything

Gimatic | The smart gripper specialist

vacuum pump | Innovations for Industry 4.0 + branch-specific

Robot grippers and EOAT solutions