Online magazine for design and development

Here you will find everything that the designer needs for his design and the development engineer for his new development, from the draft to quality assurance in production, such as new products, their applications, new technologies or research results. Company reports as well as topics on technological and megatrends in all industrial sectors complete our range of industry news. Let's start with the news.

Company News

Federal Minister of Economics Habeck visits the Turck stand

Federal Minister of Economics Dr. Robert Habeck visited the Turck Group at the Hannover Messe 2024 to find out how the automation specialist contributes to sustainability in the industry.

Annual report 2023, 247 new products and Igus Go app

Igus is presenting the new business figures and presenting 2024 new products at the Hannover Messe 247 and would like to advance the goal of “Zero Lubrication” with the Igus Go app.

IFM will increase sales to over EUR 2023 billion in 1,4

IFM Electronic was able to increase sales again in the 2023 financial year. The preliminary consolidated financial statements show a new sales record with sales of over 1,4 billion euros and growth of 3%.

Jumo Campus for sensors and measurement technology

Jumo has designed further training courses with a view to the currently exciting topics being discussed in individual sectors and offers corresponding seminars as part of the Jumo Campus.

Schaeffler AG increases sales by 2023% in 5,8

Schaeffler AG's sales increased by 2023% to EUR 5,8 billion in 16,3. Currency-adjusted sales growth was 5,8 percent, which is within the forecast for the 2023 financial year.

Industry news for your design and development from the specialist areas

Sensors

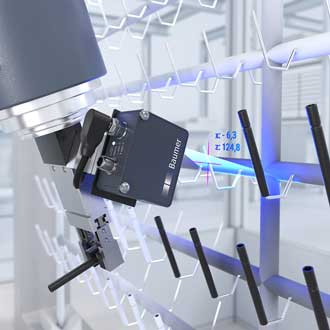

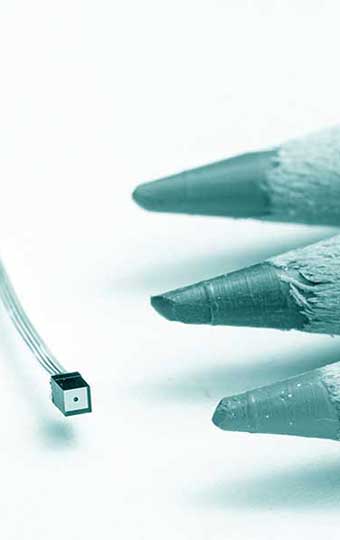

New sensor class simplifies positioning tasks significantly

The smart 2D profile sensors from Baumer define a new sensor class for precise and fast positioning and inspection tasks.

cables and wires

PTFE and PFAS free Chainflex cables

Igus gives the “PFAS free” seal to 95% of its Chainflex cables, which are free of the harmful substances PFAS and PTFE.

Drive Elements

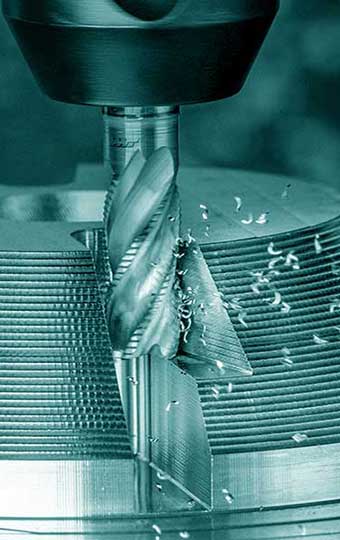

New manufacturing technologies improve crown gear production

Welter Zahnrad has further developed its production processes for crown gears and can now produce them in quality 3967 according to DIN 5.

IPC

Ex-protected tablet with augmented reality qualities

Pepperl+Fuchs is expanding its Ecom “Tab-Ex” tablet series with a device based on the robust Samsung Galaxy Tabactive4 Pro.

Industry news for your design and development from the branches

Mobile Machinery

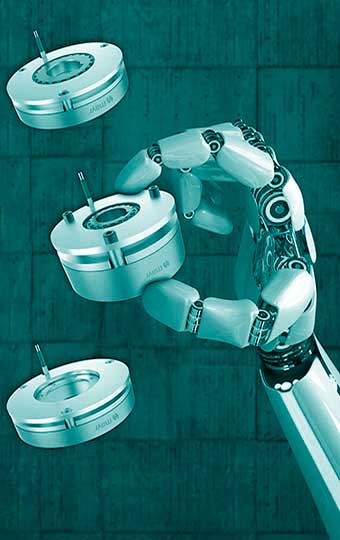

Tailor-made brakes for autonomous forklifts

Kendrion Intorq has developed innovative braking technology with Bastian Solutions for the new autonomous forklift CB18.

Mobile Machinery

Cylindrical roller bearings for heavy industrial gearboxes and construction machinery

Schaeffler is introducing new cylindrical roller bearings in which the service life has doubled and the load capacity has increased by 24%.

Automobile

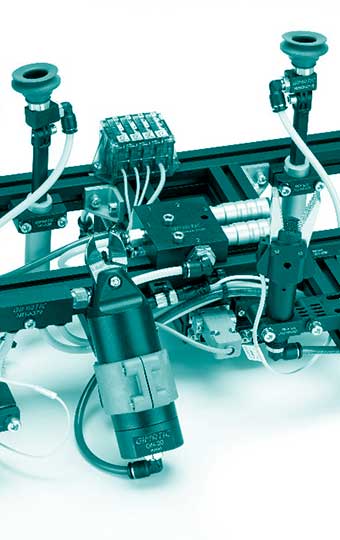

IO module secures hydrogen filling stations from Resato

Resato Hydrogen Technology has implemented a modular and scalable concept for H2 filling stations with Turck and its IO modules.

food technology

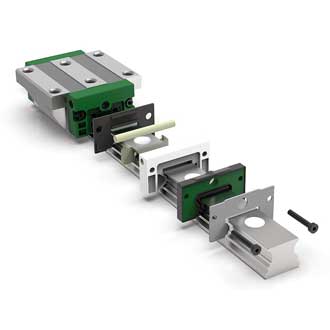

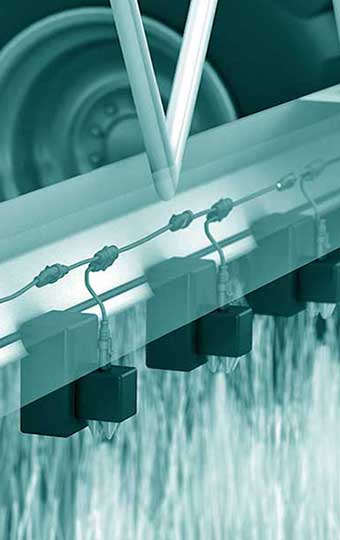

Lubrication and sealing-optimized linear guide

Schaeffler presents linear guides for food technology with optimized seals, wipers and long-term lubrication units.

Industry fair news

Hannover Messe promotes energy for sustainable industry

As a networked industrial ecosystem, the exhibitors demonstrate how climate neutrality can be achieved through the use of electrification, digitalization and automation under the guiding theme of Energizing a sustainable Industry.

Control Fair 2024 | The industry is already looking forward to Stuttgart

Control 2024, the important international trade fair for quality assurance, will take place from April 23rd to 26th in Stuttgart. The trade fair places a particular focus on automation and digitalization.

SPS Nuremberg: Now in 16 halls!

The SPS – Smart Production Solutions from November 14th to 16.11th. 2023 will see significant growth in the trade fair compared to the previous year and is on the way to pre-Corona levels.

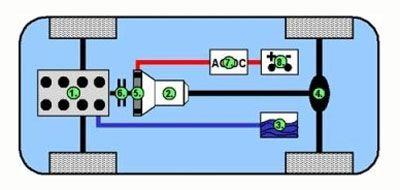

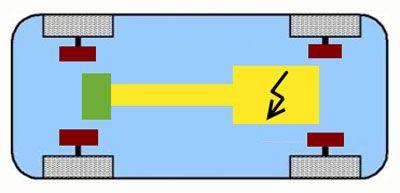

One way to counter this disadvantage is to reduce weight. With a compact design, the usable space in the car increases. The number of components is to be significantly reduced by means of a high level of system integration. Ultimately, the necessary flexibility should be achieved through front or rear-wheel drive or as a 4 x 4 without cardan shaft or axle / differential design. Every socket has to become a gas station. With the Synchron Direct Drive, ABS and ESP up to self-driving functions can be integrated and automatic evasive maneuvers can be implemented. The driving pleasure is not neglected because the drive has an overwhelming starting torque.

One way to counter this disadvantage is to reduce weight. With a compact design, the usable space in the car increases. The number of components is to be significantly reduced by means of a high level of system integration. Ultimately, the necessary flexibility should be achieved through front or rear-wheel drive or as a 4 x 4 without cardan shaft or axle / differential design. Every socket has to become a gas station. With the Synchron Direct Drive, ABS and ESP up to self-driving functions can be integrated and automatic evasive maneuvers can be implemented. The driving pleasure is not neglected because the drive has an overwhelming starting torque.

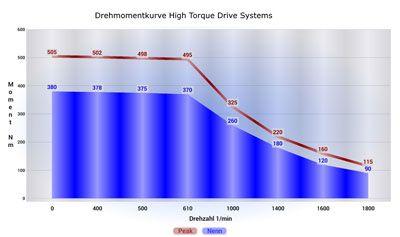

The known disadvantages of the electric drive include the gearbox, noise, high inertia, friction losses and mechanical damage due to overload. Each gear stage mechanically reduces the efficiency. The high-performance motors "HTDS-extreme" are based on a multi-pole synchronous machine. A high number of poles results in a high starting torque and a low nominal speed. These properties are the prerequisites for efficient direct drive.

The known disadvantages of the electric drive include the gearbox, noise, high inertia, friction losses and mechanical damage due to overload. Each gear stage mechanically reduces the efficiency. The high-performance motors "HTDS-extreme" are based on a multi-pole synchronous machine. A high number of poles results in a high starting torque and a low nominal speed. These properties are the prerequisites for efficient direct drive. The high starting torque is generated at low speeds. The battery power required to start up is therefore small. With the HTDS drive system, the focus is on the high efficiency of vehicle operation. As a direct drive, the High Torque Drive System sets new standards for clean mobility that is suitable for everyday use.

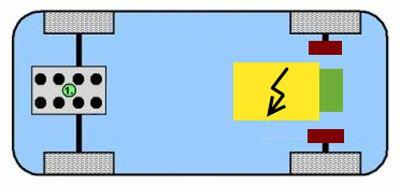

The high starting torque is generated at low speeds. The battery power required to start up is therefore small. With the HTDS drive system, the focus is on the high efficiency of vehicle operation. As a direct drive, the High Torque Drive System sets new standards for clean mobility that is suitable for everyday use. The HTDS drive concept dispenses with combustion engines, axles, transmissions, clutches and differentials. The space gained can thus be used for the passenger cell or the cargo space. The vehicles are becoming more compact, smaller and therefore lighter without compromising comfort or safety. The drive concept thus makes a significant contribution to one of the main requirements for electric vehicles: less weight for a longer range.

The HTDS drive concept dispenses with combustion engines, axles, transmissions, clutches and differentials. The space gained can thus be used for the passenger cell or the cargo space. The vehicles are becoming more compact, smaller and therefore lighter without compromising comfort or safety. The drive concept thus makes a significant contribution to one of the main requirements for electric vehicles: less weight for a longer range.