3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

Glass & ceramics for industry

Technical glass for displays or panes as well as high-performance ceramics, industrial ceramics, engineering ceramics or as a symbiosis of glass ceramics

Image: LPKF / Vitrion

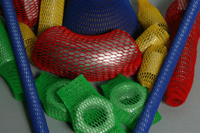

plastics as an alternative

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Metals for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

Composites for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

Surface technology for the coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Here you will find modern new ones Materials, Technologies and Process for their treatment or processing for mechanical and plant engineering as well as many other branches of industrial production, including materials such as glass, ceramics, plastics, Metals and Composites as well as procedures like 3D pressure and Surface Technology.

Contents

The development of modern Materials and processes for industrial applications are decisively characterized by energy saving, lightweight construction, environmental protection and sustainability. Material developers and researchers work on the performance and cost efficiency of new materials. And so materials science and materials science are subject to constant change and new alloys of steel or innovative filaments for 3D printing are being created, for example. Of course, all these materials also have to be processed. In addition, we examine manufacturing processes, the processing of raw materials and technologies for shaping, etc.

The following materials and processes are for specific industries like that Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Microsystems Technology been developed. You will also find new materials here, which Applied research has developed.

The engineering of the modern material goes hand in hand with an efficient process that can process it. That happens especially in Machinery and plant engineering to carry. We report below on both sides: Innovations of new materials and new processes for their processing:

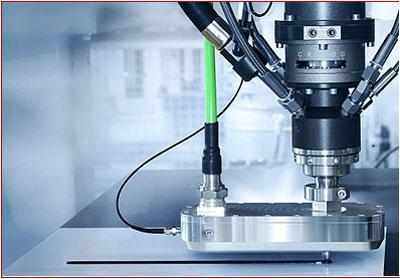

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

Sliding elements made of tribopolymers with integrated solid lubricants from Faigle score with low friction and high wear resistance. They can run dry and have good emergency running properties. In addition, they are light in weight, have good corrosion resistance and resistance to chemicals. They run quietly and are not very sensitive to impacts. There are a number of such sliding materials:

Sliding elements made of tribopolymers with integrated solid lubricants from Faigle score with low friction and high wear resistance. They can run dry and have good emergency running properties. In addition, they are light in weight, have good corrosion resistance and resistance to chemicals. They run quietly and are not very sensitive to impacts. There are a number of such sliding materials:

With "Raku Tool" the Rampf Group offers model and mold making materials and complete solutions based on them for carbon fiber and glass fiber composite materials. The company covers the demand with three competence centers worldwide.

With "Raku Tool" the Rampf Group offers model and mold making materials and complete solutions based on them for carbon fiber and glass fiber composite materials. The company covers the demand with three competence centers worldwide.

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

Components that are to be coated in the KTL process are generally hung or plugged into special devices before they are immersed in the various baths. In addition to constructive measures in the design of the workpieces, the construction of these product carriers also contributes to a good coating result. That is why Ebbinghaus Styria Coating pays particular attention to the design and manufacture of these product carriers.

Minitec manufactures Precision shafts now also in series. The provider of a modular system with aluminum profiles and Linear Technology offers cutting, axial and radial processing as well as milling. To this end, the company has equipped itself with the latest technology at its Waldmohr site in Rhineland-Palatinate.

Minitec manufactures Precision shafts now also in series. The provider of a modular system with aluminum profiles and Linear Technology offers cutting, axial and radial processing as well as milling. To this end, the company has equipped itself with the latest technology at its Waldmohr site in Rhineland-Palatinate.

Whether the automotive, energy, automation or household industries: they are all heavily dependent on advances in the storage and transport of electrical energy. As a result, electro casting resins are a key technology driver in these and other industries. Rampf Polymer Solutions presents high-performance silicone, polyurethane and epoxy casting resins with maximum thermal conductivity.

Whether the automotive, energy, automation or household industries: they are all heavily dependent on advances in the storage and transport of electrical energy. As a result, electro casting resins are a key technology driver in these and other industries. Rampf Polymer Solutions presents high-performance silicone, polyurethane and epoxy casting resins with maximum thermal conductivity.

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

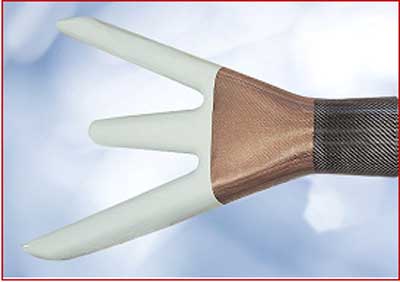

Rampf presents a structural resin for the fairing in the aircraft main landing gear and a cyanate ester infusion system for the Composite Aviation manufacturing. The new cladding replaces the previous aluminum shell, thus avoiding problems caused by natural frequencies. The low-viscosity infusion system offers first-class mechanical properties. Both innovations meet the high demands on the Fire protection.

Rampf presents a structural resin for the fairing in the aircraft main landing gear and a cyanate ester infusion system for the Composite Aviation manufacturing. The new cladding replaces the previous aluminum shell, thus avoiding problems caused by natural frequencies. The low-viscosity infusion system offers first-class mechanical properties. Both innovations meet the high demands on the Fire protection.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

The "Preeflow Eco-PEN300 1K" dispenser from Viscotec ensures optimal surface technology processes and low material consumption in automated use. Applications can be found everywhere: for example on steering wheels and grilles for cars, excavators and tractors, on coffee machines, refrigerators and other household appliances.

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.

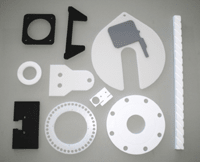

Karl Späh is further expanding its plastics processing capacities. With a new generation of multifunctional plotters, precise plastic parts up to a size of 3 x 2 m and a maximum thickness of 70 mm can be produced for all areas of industry and technical trade. And this in any desired shape and quantity from batch size 1. The milled parts can be made from all common plastics such as PA, PC, PE, PEEK, POM, PP, PS, PTFE, PVC and many more.

Machine and vehicle parts are manufactured with the highest precision. Even the smallest scratches can impair the function and lead to complaints. To avoid this, quality management should always include transport protection for components with sensitive surfaces. As a solution, "Poly-Net" interlayer grids for load carriers from the North German submarine cable works offer themselves.

Machine and vehicle parts are manufactured with the highest precision. Even the smallest scratches can impair the function and lead to complaints. To avoid this, quality management should always include transport protection for components with sensitive surfaces. As a solution, "Poly-Net" interlayer grids for load carriers from the North German submarine cable works offer themselves.

The new FIP CC technology (Formed-In-Place Closed-Cell) from Sonderhoff brings together the high water resistance of the silicone world and the attractive material costs of the polyurethane world. The foam seals "Fermapor CC" based on PUR are room temperature crosslinking 2-component systems that use the FIP CC foaming process to form a very fine-cell, predominantly closed-cell, soft foam seal.

The new FIP CC technology (Formed-In-Place Closed-Cell) from Sonderhoff brings together the high water resistance of the silicone world and the attractive material costs of the polyurethane world. The foam seals "Fermapor CC" based on PUR are room temperature crosslinking 2-component systems that use the FIP CC foaming process to form a very fine-cell, predominantly closed-cell, soft foam seal.