3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

3D printing for additive manufacturing

3D printing process, 3D printer, filament or printing material, etc. for modern mechanical engineering and special industries

Image: Fraunhofer IWU

Glass & ceramics for industry

Technical glass for displays or panes as well as high-performance ceramics, industrial ceramics, engineering ceramics or as a symbiosis of glass ceramics

Image: LPKF / Vitrion

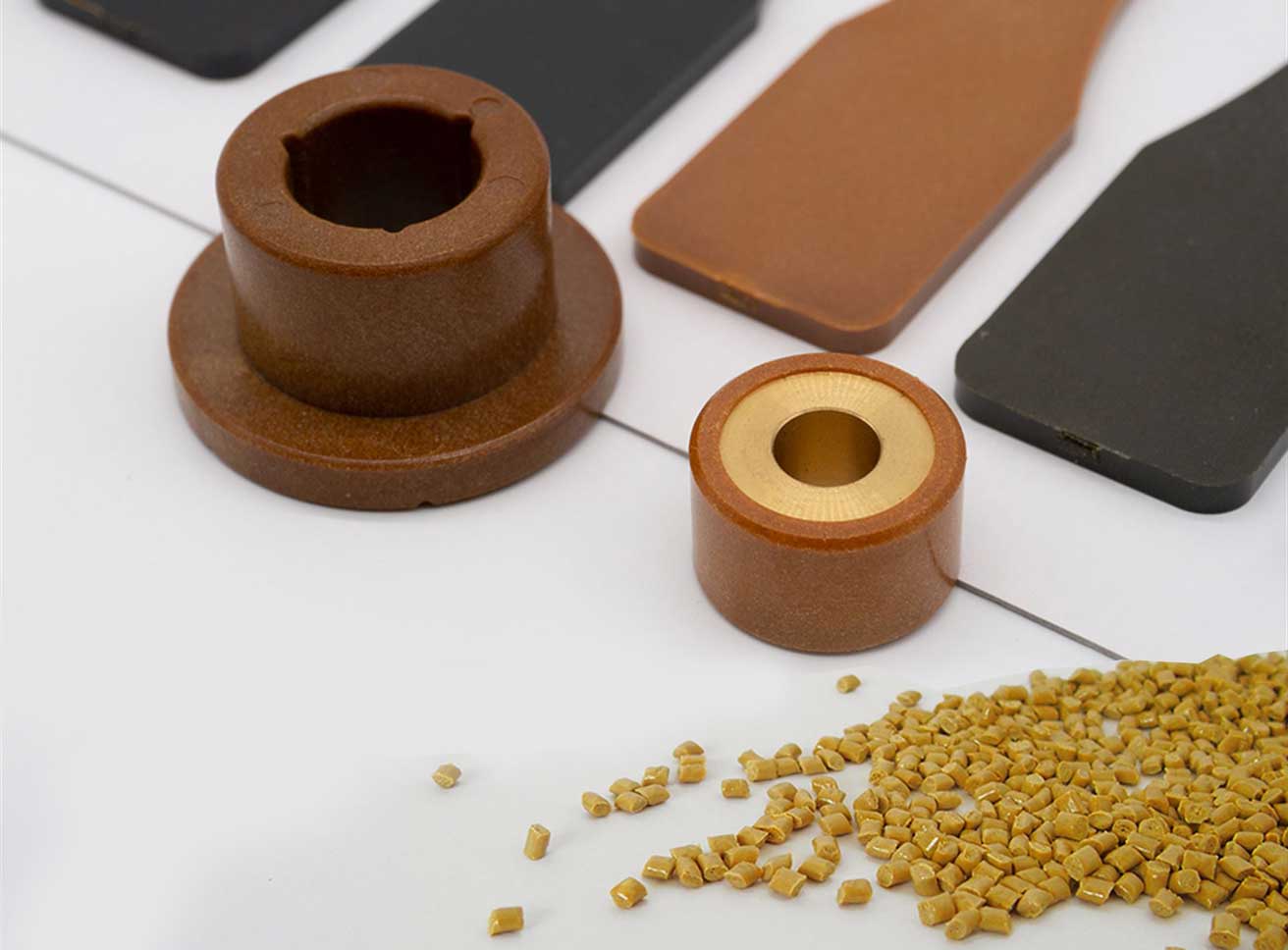

plastics as an alternative

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Metals for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

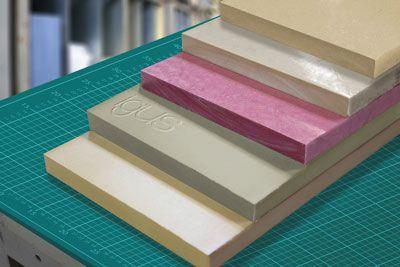

Composites for new properties

High-performance compounds, natural fiber compounds, glass fiber reinforced plastics, thermoplastic composites and fiber composites

Image: Vienna University of Technology

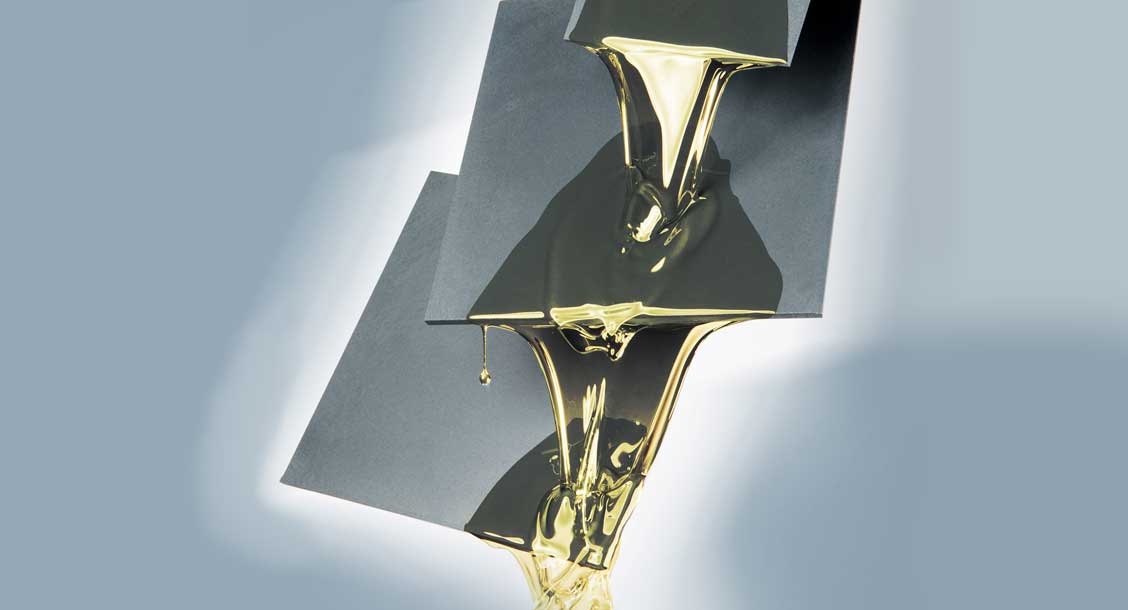

Surface technology for the coating

Coatings by painting, powder coating as well as PVC coatings, surface refinement, dosing, lasering give robustness and shine

Image: Heraeus

Here you will find modern new ones Materials, Technologies and Process for their treatment or processing for mechanical and plant engineering as well as many other branches of industrial production, including materials such as glass, ceramics, plastics, Metals and Composites as well as procedures like 3D pressure and Surface Technology.

Contents

The development of modern Materials and processes for industrial applications are decisively characterized by energy saving, lightweight construction, environmental protection and sustainability. Material developers and researchers work on the performance and cost efficiency of new materials. And so materials science and materials science are subject to constant change and new alloys of steel or innovative filaments for 3D printing are being created, for example. Of course, all these materials also have to be processed. In addition, we examine manufacturing processes, the processing of raw materials and technologies for shaping, etc.

The following materials and processes are for specific industries like that Automotive industry, Renewable energies, Technical Building Services, Medical Technology, Microsystems Technology been developed. You will also find new materials here, which Applied research has developed.

The engineering of the modern material goes hand in hand with an efficient process that can process it. That happens especially in Machinery and plant engineering to carry. We report below on both sides: Innovations of new materials and new processes for their processing:

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

At the TUM the processing of new materials with existing production methods in bending technology has been taken on. Using the practical example of a free-form bending machine from J. New plays the IoT CNC control module DAU from Mitsubishi Electric an essential role. At the Chair of Forming Technology and Casting of Prof. Dr.-Ing Wolfram Volk, research is currently being carried out on projects that could bring decisive further developments for bending technology.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. The plastics specialist now has one for small series or series production in injection molding, a prototype from the 3D printer or semi-finished products Offline configurator Developed for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

The engineering plastic polyamide Above all, it offers high strength, good oil resistance and is very durable. the BASF has recently expanded its portfolio with a flame-retardant PA66 polyamide type. In strong orange one comes to the strong dye demand in the Automotive sector to. You can find these and other polyamide innovations below:

Sherpa Robotics sets with his camera controlled Six-axis robot for the automated loading of components on CNC machines machine frame made from epument mineral casting Rampf Machine Systems. The epoxy resin bonded material ensures the necessary stability of the “Sherpaloader” with a very good ecological balance. Not least because from now on the mineral cast will be produced without the addition of hard coal fly ash.

For sealing and encapsulating components, the Rampf group the material, the machines and the processing, in short the entire range. The 2-component polymer systems are based on polyurethane, epoxy or silicone. When it comes to mixing and dosing systems, the company is a leader and with contract manufacturing, the appropriate service is not neglected. Below you will find the news on this with a focus on the materials such as Liquid seal, adhesive and potting compound:

Tanaka Precious Metals has technology to wiring developed from nanosilver for the production of flexible touch displays with high image quality on film substrates. A new nanosilver ink, which can be sintered at as little as 70 °C, is suitable both for printing invisible circuit paths on plastics and for producing flexible metal films for etching using the ITO process.

Tanaka Precious Metals has technology to wiring developed from nanosilver for the production of flexible touch displays with high image quality on film substrates. A new nanosilver ink, which can be sintered at as little as 70 °C, is suitable both for printing invisible circuit paths on plastics and for producing flexible metal films for etching using the ITO process.

The additive manufacturing, also known as 3D Print, encompasses various technologies, all based on the same fundamental concept: the layer-by-layer construction of an object. These include techniques such as Stereolithography (SLA), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Direct Metal Laser Sintering (DMLS), to name a few. What is behind each Process hides, find out here.

With the development of a new 3D laser center, Kiesling Maschinentechnik is expanding the range of services of its "Perforex"switch cabinetmachining centers clearly. In addition to flat parts, control and switchgear manufacturers can also process complete housings and control cabinets quickly and precisely using laser cutting. The new development is very well suited for use with stainless steel, but also with sheet steel and powder-coated sheets. Rittal

With the development of a new 3D laser center, Kiesling Maschinentechnik is expanding the range of services of its "Perforex"switch cabinetmachining centers clearly. In addition to flat parts, control and switchgear manufacturers can also process complete housings and control cabinets quickly and precisely using laser cutting. The new development is very well suited for use with stainless steel, but also with sheet steel and powder-coated sheets. Rittal

The BASF presents a new one Engineering plasticwho is particularly good Automotive components protects against contact with hot oil. The polyethersulfone (PESU) Ultrasound E0510 C2TR offers very good tribological properties, dimensional stability even under large temperature fluctuations as well high resistance to oil.

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

Mold making Thorsten Michael has developed a process with which Surfaces made of lightweight Arpro Laser foam let it be designed in any way you like during foaming and injection up to a depth of 1,5 mm. This is made possible by the Lasertec Shape technology for laser cutting of foams, with which structures can be reproduced precisely in geometrically precisely defined 3D areas. Additional coatings or cladding can now also be superfluous.

Copper is an efficient material when construction planners are looking for a sustainable material. Important changes in European environmental certification are now recognized according to German copper institute the contribution that copper can make to the circular economy. The changes to the published in October 2019 Standard EN 15804 contain core rules for product categories (PCR) for type III environmental declarations for every construction product and construction work.

Copper is an efficient material when construction planners are looking for a sustainable material. Important changes in European environmental certification are now recognized according to German copper institute the contribution that copper can make to the circular economy. The changes to the published in October 2019 Standard EN 15804 contain core rules for product categories (PCR) for type III environmental declarations for every construction product and construction work.

The GSO Surface Technology uses over 1000 different paints every year to coat components for a wide variety of industries. The trend is towards more individual products with smaller batches and frequent color changes. Automation and the early one Coating thickness measurement with the non-contact testing system Paintchecker mobile from optisense play a key role in maintaining the quality level and increasing productivity.

The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering Plastic with high production efficiency in injection molding. The thermal plastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. As a distributor for PI Meldin from Saint-Gobain, Bieglo presents the PI portfolio, which is also suitable for the 3D pressure suitable.