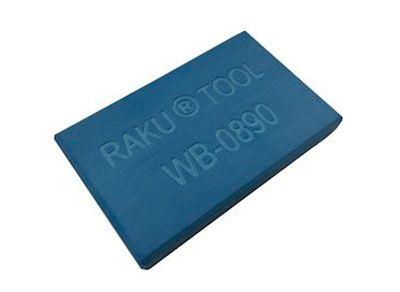

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

Rampf Tooling Solutions presents the new epoxy block material “Raku Tool WB-0890”, specially developed for the composite industry. The semi-finished product has an extremely fine surface structure, which significantly reduces both the finishing effort and the sealant consumption.

In addition, the surface quality can be transferred from the master model to the prepreg mold, so that no regrinding of the mold is required and the service life of the prepreg molds is significantly increased. The epoxy block material can be milled quickly and easily and is compatible with all paints, release agents and epoxy prepregs customary in the industry. The glass transition temperature Tg is 110 ° C.

In addition, the company has developed two more innovative epoxy systems for composite manufacturing. The low-viscosity, low-temperature, fast-curing Raku EI-2508 FST system is used indoors in aircraft and rail vehicles, as well as other applications requiring flame-retardant properties.

Industrial liquid gasket, adhesive and potting compound

Industrial liquid gasket, adhesive and potting compound

The cured high-temperature epoxy system "Raku EI-2510" has excellent hot-wet properties (dry Tg 210 ° C, wet Tg 174 ° C). as well as a high breaking strength. Raku EI-2510 is used in a wide variety of structural applications in the high temperature range. The 2K system, which can be processed at low temperatures, requires considerably less investment in tools and infrastructure. In addition, no special storage is necessary.