Special surface treatment for linear guides in rail vehicles

- Details

- Hits: 7734

In order for railway trains to operate optimally, all moving mechanical parts must meet demanding requirements for performance and maintenance. Robust, corrosion-protected components are essential for the long-term reliable functioning of the rolling stock. The great Rollon The product portfolio with corrosion-protected linear and telescopic guides as well as guides made of stainless steel offers suitable solutions for all rail technology.

In order for railway trains to operate optimally, all moving mechanical parts must meet demanding requirements for performance and maintenance. Robust, corrosion-protected components are essential for the long-term reliable functioning of the rolling stock. The great Rollon The product portfolio with corrosion-protected linear and telescopic guides as well as guides made of stainless steel offers suitable solutions for all rail technology.

Railway components are subject to moisture, brake dust, dirt and corrosive substances which can damage the components of the trains. Even seemingly inconspicuous substances like human hair can accumulate over time and compromise the smooth operation of train components.

Railway components are subject to moisture, brake dust, dirt and corrosive substances which can damage the components of the trains. Even seemingly inconspicuous substances like human hair can accumulate over time and compromise the smooth operation of train components.

Among the most sensitive components in this context are the telescopic ones linear guides doors, wheelchair and stroller access ramps, and service access to generators, battery compartments, and HVAC systems. These components are particularly vulnerable to corrosion because the guides must remain closed while trains are running or parked. Dirt and moisture are then trapped within the mechanisms and can insidiously cause permanent damage.

Igus linear guide as a quiet, maintenance-free alternative

Igus linear guide as a quiet, maintenance-free alternative

Salt spray test outperformed by 44%

To make matters worse, that the maintenance often takes place only sporadically and at long intervals. For telescopic guides and other linear guides to work reliably over the guaranteed lifetime, the metal parts must be provided with durable anti-corrosion coatings. In fact, the most demanding rail applications require components that can withstand the industry standard ISO 9227 NSS (neutral salt spray) salt spray test up to 500 h. The "Rollon Aloy" surface treatment used for this purpose is used in the Rollon guides. It has recently outperformed this standard by 44%: The component has survived the salt spray test for a period of 720 hours without the slightest sign of corrosion.

Surface treatment against corrosion

Rollon Aloy is a RoHS-compliant trivalent chromium treatment originally used in the automotive industry as a replacement for environmentally and harmful hexavalent chromium treatments. After galvanizing in accordance with ISO 2081, Rollon Aloy is applied in a comprehensive passivation process. The application of the passivation layer essentially creates a barrier that significantly improves the corrosion protection of metal parts.

Rollon Aloy is a RoHS-compliant trivalent chromium treatment originally used in the automotive industry as a replacement for environmentally and harmful hexavalent chromium treatments. After galvanizing in accordance with ISO 2081, Rollon Aloy is applied in a comprehensive passivation process. The application of the passivation layer essentially creates a barrier that significantly improves the corrosion protection of metal parts.

This protective layer resists wear, friction and corrosive substances exposed to moving parts. It keeps the parent metal intact and extends its life. Rollon Aloy is suitable for all types of linear guides and is recommended for railway applications where moving metal parts are regularly exposed to severe environmental conditions such as high humidity, dirt particles, brake wear and many other corrosive substances. The specialist in linear technology also offers surface treatments that are suitable for less demanding applications in rail technology, for example, parts that are less frequently moved or better shielded from harmful environmental influences.

Infrared heater for efficient heat processes in industry

Infrared heater for efficient heat processes in industry

Besides Rollon Aloy, electrolytic plating and electroless nickel plating are anti-corrosion methods recommended for use in the railway industry. Electrolytic plating, also known as galvanizing, applies a thin layer of zinc to the base metal using an electrical plating process. The main advantages of this surface treatment are the resistance to corrosion and the fact that the treated surfaces can be easily painted.

Chemical nickel plating improves corrosion resistance by moving metal parts, e.g. B. the rails of linear guides, a thin protective layer of chemically treated nickel is added. Other benefits of this process, beyond corrosion protection, include improved hardness and wear resistance, and an extremely tight tolerance on the thickness of the coating, improving the linear precision of moving parts. The thickness of the surface treatment is determined by the duration of the nickel plating process.

Surface pretreatment important for performance

Surface preparation is another factor that has a significant impact on the quality and performance of coated metal parts. If the surfaces of the parent metal are not pretreated properly prior to application of the coatings, even the best coating will not produce the expected performance. The correct pretreatment of the metal

Surface preparation is another factor that has a significant impact on the quality and performance of coated metal parts. If the surfaces of the parent metal are not pretreated properly prior to application of the coatings, even the best coating will not produce the expected performance. The correct pretreatment of the metal

involves strict adherence to a multi-step process that already improves the strength of the base metal and surface finish before applying the final anti-corrosion coating. Although some manufacturers take one or two shortcuts when preparing the surface, Rollon follows a comprehensive process in the rail finishing processes, with a series of steps to ensure the usual quality.

Linear guide rails on trains

Railway trains use various types of these robust components, including both linear guides and telescopic rails. They can be found on sliding seats, doors and tables in the passenger areas and allow the movement of access doors for passengers and ramps for wheelchairs, strollers and luggage. On the technical side, pull-out containers for the maintenance of batteries or HVAC systems are added.

Barrier-free access to the passenger compartment requires retractable sliding steps in the entrance area of the doors. The “Compact Rail” with its many designs and self-alignment on two levels has proven itself here. It achieves high travel speeds and is insensitive to dirt - an important criterion for applications on the floor and at the transition to the outside area. Embossed X-Rail guide rails are suitable for adjustable tables. The "X-Rail" product family can be used very well in applications where a favorable price-performance ratio and high resistance to corrosion are required. They are also available with stainless steel guide rails.

Barrier-free access to the passenger compartment requires retractable sliding steps in the entrance area of the doors. The “Compact Rail” with its many designs and self-alignment on two levels has proven itself here. It achieves high travel speeds and is insensitive to dirt - an important criterion for applications on the floor and at the transition to the outside area. Embossed X-Rail guide rails are suitable for adjustable tables. The "X-Rail" product family can be used very well in applications where a favorable price-performance ratio and high resistance to corrosion are required. They are also available with stainless steel guide rails.

The tip of the train front is often slidably installed for maintenance purposes or to lower the coupling unit - exactly the right place for the full extension "Opti Rail LTH". Thanks to the high geometrical moment of inertia, this type of telescopic slide is extremely compact and very rigid with high load ratings. Extendable battery boxes also have to carry special loads. For this purpose, the application engineers recommend, for example, type DSS telescopic runners. They have the necessary rigidity with a slim design. This results in a high load capacity with low deflection in the extended state.

Efficient linear guide with lubrication status monitoring

Efficient linear guide with lubrication status monitoring

The stainless steel version of the curve guide "Curviline" is used for all non-linear special movements. The guide consists of AISI 316L with rollers made of AISI 440. The variants with constant or variable radii are specially manufactured according to customer drawings. The runners have four rollers arranged in pairs and hold the preload over the entire length of the rail.

If particularly heavy loads have to be carried, the particularly robust and resistant partial, full and over-extension runners and telescopes from the "Hegra Rail" product family are ideal.

Results of salt spray tests

The durability of the Rollon components with and without corrosion protection was tested in the salt spray test. According to ISO 9227, multiple rails of linear guides are placed in a test chamber and exposed to a five percent sodium chloride solution (NaCl) with a pH of 6,5. The neutral NaCl solution is sprayed as a continuous mist at 35 ° C with a nebulizer nozzle for the duration of the test. The evaluation of the test items takes place at predetermined time intervals:

The durability of the Rollon components with and without corrosion protection was tested in the salt spray test. According to ISO 9227, multiple rails of linear guides are placed in a test chamber and exposed to a five percent sodium chloride solution (NaCl) with a pH of 6,5. The neutral NaCl solution is sprayed as a continuous mist at 35 ° C with a nebulizer nozzle for the duration of the test. The evaluation of the test items takes place at predetermined time intervals:

The inspectors carry out measurements to determine the quality of the surface protection and the corrosion resistance of the various test pieces. The results of the salt spray tests have shown that Rollon Aloy coated linear guides have withstood 720 h without any apparent signs of corrosion. Rollon Linear Guides, which had been treated with two nickel plating processes, withstood around 360 hours in the test. A specimen that had been electrolytically electroplated exhibited less than half the durability of the Rollon Aloy in the salt spray. Other comparison guides performed even worse. After only 120 h in the salt spray, the corrosion protection coatings of a competitor had already completely decomposed. The tested rails included one with a standard galvanizing and another with a nitrocarburised coating.

Lubricate or not lubricate?

Coatings are not the only way to extend the life of LM railways. Lubrication also plays a role, although there is no agreement on this topic. Some railways refrain from using external lubricants on linear guide components. They rightly assume that there is a risk of the lubricants picking up particles that stick to the guide over time. Other operators do not see this risk of contamination and use lubricants to extend the life of the linear guides. Both variants, depending on the application, have their advantages and disadvantages. However, operators should keep in mind that using an external lubricant sparingly can significantly extend the life of linear guideways: testing has shown a lifetime extension by a factor of 10 or more when lubrication is used. The operators should prefer high temperature fats.

Picture above: In this chamber, the salt spray test was carried out according to ISO 9227.

You might also be interested in...

Cobot | Discover collaborative robots as a new employee

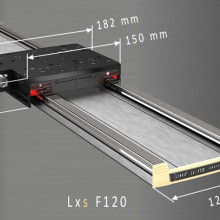

linear guide | Precise, light, durable

Rollon | The engineering partner

Linear axis | Precision and drive diversity

Telescopic rails | For furniture, cars, industry

Heavy duty rails | High loads welcome

Klaus Hermes is Marketing Manager at Rollon GmbH in Düsseldorf.