Cleaning, deburring and painting of surfaces

- Details

- Hits: 8657

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

Benseler Sachsen GmbH & Co. KG shows the entire spectrum of its professional surface treatment and provides information on the processes of electrochemical metal processing, thermal deburring and wet painting. The wet paint coating for large-area plastic add-on parts such as spoilers in the automotive sector is one of the new surface coating processes. Since lighter components made of carbon fiber-reinforced plastics are increasingly being used in vehicle construction, the Saxon surface coater also has the necessary know-how for this.

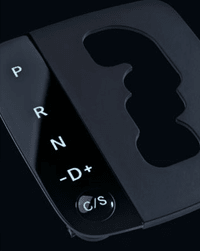

Wet paint is the first choice when it comes to particularly high-quality and glossy surfaces - from black high gloss to colored clear coat. But also for wet paint coatings of steel, aluminum and magnesium, the company has a comprehensive know-how and met thanks to its own cataphoretic dip painting and powder coating equipment highest standards in corrosion protection - as evidenced in the climate change test.

When mechanical production reaches its limits, electrochemical metalworking is used. Metal workpieces are not only deburred and polished with electrochemistry, but also processed. Defined shapes can be incorporated. A particular challenge is the electrochemical shaping of internal bore intersections with complicated component geometry, such as in injection systems. In addition to pure metalworking of parts for the automotive industry or medical technology, the manufacturer also offers development services in this area. The workpieces are given the finishing touches when surfaces are refined, for example during electrochemical polishing with roughness values of Rz <2 µm and Rpk <0,3 µm.

In thermal deburring, all burrs present on the workpiece are burned within milliseconds in a de-burring chamber filled with an oxygen-fuel gas mixture. The procedure guarantees with the correct part acceptance the complete deburring at all necessary places also hard to reach in only one operation.