Material selection for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

Material selection for mechanical engineering

Steel, copper and precious metals, alloys or aluminum for lightweight construction as well as profiles, bent parts or laser parts for the development of new industrial goods

Image: HP Kaysser

Here we report on new materials from the Metal Area. The development of new industrial goods requires innovations in steel, copper as well as precious metals, alloys or aluminum for lightweight construction. Processed metal can also be found here Materials such as profiles, bent parts or laser parts. So the right one succeeds material selection.

Content:

The material Metal is essential for industrial production. About 80% of the chemical elements in the periodic table are metals. The material metal is used in machine and plant engineering. If the applications become more difficult and properties such as corrosion protection are required, then comes precious metals or Stainless Steel as used in medical technology or in the food industry.

Here you will find exciting news about the Material metal from Tata, Tanaka or the new Swiss Steel Group. Find out more about the optimal choice of materials for your construction:

November 06.11.2023, 300 | The LHL1700-XNUMX core shooter is characterized by short cycle times, robustness and finesse Laempe Mössner Sinto GmbH. The built-in components ensure robustness Profile rail guides from Schaeffler. They can accommodate a limit load of 300 t under adverse conditions such as foundry technology.

November 06.11.2023, 300 | The LHL1700-XNUMX core shooter is characterized by short cycle times, robustness and finesse Laempe Mössner Sinto GmbH. The built-in components ensure robustness Profile rail guides from Schaeffler. They can accommodate a limit load of 300 t under adverse conditions such as foundry technology.

Minitec manufactures Precision shafts now also in series. The provider of a modular system with aluminum profiles and Linear Technology offers cutting, axial and radial processing as well as milling. To this end, the company has equipped itself with the latest technology at its Waldmohr site in Rhineland-Palatinate.

Minitec manufactures Precision shafts now also in series. The provider of a modular system with aluminum profiles and Linear Technology offers cutting, axial and radial processing as well as milling. To this end, the company has equipped itself with the latest technology at its Waldmohr site in Rhineland-Palatinate.

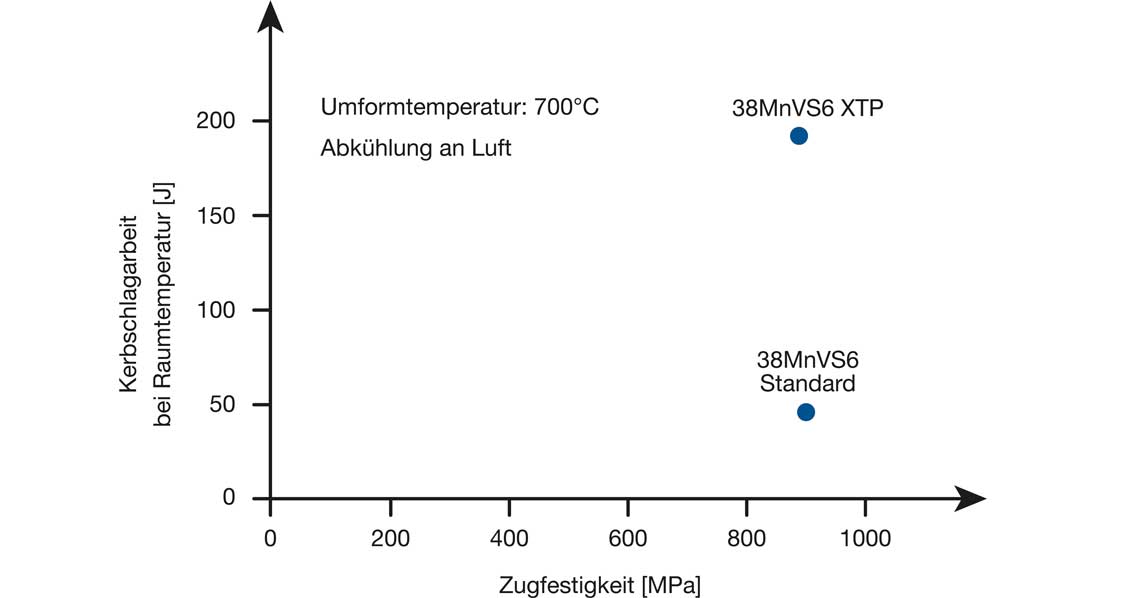

Steeltec (Schmolz + Bickenbach) opens up users of high-alloy steel now a solution that combines high performance with price stability. The subsidiary of the Schmolz + Bickenbach Group is turning its Xtreme performance Technology (XTP) on precipitation hardening ferritic-pearlitic (AFP) steels. The resulting fine grain increases the room temperature Impact strength by more than 50% up to 150 J with high strength.

Wolfensberger is pressing ahead with the development of a molding and casting process for the manufacture of thin-walled cast steel parts. This could set the course for securing future competitive strength in sand casting. The aim of the new process is to manufacture cast steel parts using the sand casting process with wall thicknesses from 2 mm, which offer new and interesting market opportunities.

Wolfensberger is pressing ahead with the development of a molding and casting process for the manufacture of thin-walled cast steel parts. This could set the course for securing future competitive strength in sand casting. The aim of the new process is to manufacture cast steel parts using the sand casting process with wall thicknesses from 2 mm, which offer new and interesting market opportunities.