Digitization and the associated changes in the manufacturing industry have also affected the area of laser-based manufacturing technologies. There are now more and more platforms like HP Kaysser Laserteile4you or Laserhub, on which one Bent parts and laser parts online can calculate and order. In the future now Artificial intelligence Assess the manufacturing process and improve real-time ordering. You can find out more about this in this article.

Contents

- With AI to real-time in powder coating - Interview

- Laser parts online variety at Laserteile4you

- Sheet metal parts and laser cutting online from Laserhub

- How much does an hour of laser cutting cost?

With AI to real-time in powder coating

02.05.2023/XNUMX/XNUMX | “When it comes to trends, we like to be ahead of the game,” says Achim back of the head, Managing Director at HP Kaysser GmbH + Co. KG and sponsor of the online ordering platform for individually manufactured metal components. With the sales brand Laserteile4you, the pioneer started a trend in 2010 that is now being imitated by a number of people. Artificial intelligence (AI) is now to be integrated. In the interview, Mr. Hinterkopf answers questions that provide an outlook:

02.05.2023/XNUMX/XNUMX | “When it comes to trends, we like to be ahead of the game,” says Achim back of the head, Managing Director at HP Kaysser GmbH + Co. KG and sponsor of the online ordering platform for individually manufactured metal components. With the sales brand Laserteile4you, the pioneer started a trend in 2010 that is now being imitated by a number of people. Artificial intelligence (AI) is now to be integrated. In the interview, Mr. Hinterkopf answers questions that provide an outlook:

What can the AI do in an ordering platform for CNC components?

"We develop together with a research institute and a university as well as our own IT team AI Algorithms for transparent and faster offers for powder-coated parts. What already works with conventional algorithms in forming and machining processes is not yet possible with powder coating. This process is so complex, with so many variables, that customers have had to wait a short time to find out if their part can be powder coated and what it will cost. In the future it will be a matter of seconds."

Why is this only possible with artificial intelligence?

"The decisive factor here is the possibility of powder coating to check at all. The following questions need to be clarified:

- Is the part designed by the customer powderable at all?

- Can it be hung?

- Does it have a hole in the right place?

- Are there no places where paint can collect?

- How must the paint application be in the various places?

- How can I optimize powder recovery?

- How many parts can be combined to form a pendant of the same color?

- How long does it take to drive through the facility?

The interaction of all these aspects is so complex that at the moment nobody can offer this to the customer fairly in real time without AI. Our goal is called real time. The system is fed with an extensive database, is operated fully automatically and learns with every order. We will do pioneering work there again."

Is it worth the effort for the manageable gain in time?

"That's not what it's about. In online business, users always expect instant feedback. In order to be able to deliver it in real time, we take the effort with the development of AI. But it's also about the development of the company as a whole example as next stage of expansion suggests that the system can suggest improvements and optimisations from the point of view of powder coating in terms of cost optimization for the customer. The system should be able to tell him: 'If you construct the part one way or another, it's cheaper for you.' In this way, a monologue becomes a dialogical system that communicates with the customer. We are developing further from fully automatic production to – if you like – automated design advice. But that's only possible with artificial intelligence."

Laser parts online variety at Laserteile4you

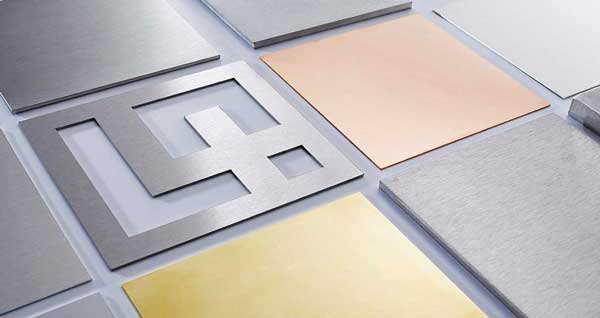

10.03.2021/4/XNUMX | LaserteileXNUMXyou is a service of HP Kaysser GmbH + Co. KG and offers the processing of sheet steel, stainless steel, aluminum and non-ferrous metal from 1 piece to series production.

10.03.2021/4/XNUMX | LaserteileXNUMXyou is a service of HP Kaysser GmbH + Co. KG and offers the processing of sheet steel, stainless steel, aluminum and non-ferrous metal from 1 piece to series production.

Since March 2021, new manufacturing processes and processing options have completed the range of laser parts in steel, stainless steel, aluminum and non-ferrous metal that can be ordered online. In addition to metal blanks and bent parts, stamped parts, laser parts and tube laser parts as well as powder-coated laser parts can now also be ordered.

Also the choice of materials and the range of sheet thicknesses increased. Non-ferrous metals such as copper or brass can now be selected. The sheet thicknesses range from 0,5 mm to a maximum of 20 mm. Also new is the 3D metal printingwith which the additive manufacturing Realize complex geometries.

Foam laser technology from Arpro to a depth of 1,5 mm

Foam laser technology from Arpro to a depth of 1,5 mm

The company sees itself as a pioneer of online ordering and is now continuing its successful expansion strategy in the Alpine country. “Commercial customers now have in Austria the same diverse options for online sheet metal ordering as in Germany, ”reports Achim Hinterkopf from the management of the founding company H. P. Kaysser and responsible for Laserteile4you.

Modern powder coating for colored sheet metal parts

The offer to colored sheet metal parts is made possible by a new, high-performance powder coating system. With it, the entire color spectrum can be implemented.

Many regular commercial customers have been using the online service for many years, such as small businesses and industrial companies in almost all sectors, including mechanical engineering, trades and the Automotive industry. This allows you to reduce your vertical range of manufacture by simply ordering and now the laser parts that used to be laboriously manufactured in-house have them made by professionals.

The possibility around the clock Being able to calculate the laser parts requirement and order with one click is very much appreciated by many customers.

The possibility around the clock Being able to calculate the laser parts requirement and order with one click is very much appreciated by many customers.

The Handling the procurement platform is very simple. The program guides the user to their goal in a user-friendly manner. It is clear and self-explanatory from uploading the drawing, selecting the material, through the processing steps to entering the desired date.

Pioneers in sheet metal working online

The family company is behind Laserteile4you HP Kaysser GmbH + Co. KG from Nellmersbach near Stuttgart. The online portal set up in 2010 is considered a pioneer for the professional ordering of individually manufactured sheet metal parts via the Internet. In Austria and Germany alone, more than 30.000 customers use the opportunity to calculate and order extensive sheet metal processing in an impressive variety of materials around the clock.

Managing director Thomas Kaysser guides through the production

Sheet metal parts and laser cutting online from Laserhub

22.01.2020/XNUMX/XNUMX | Bent parts and laser parts also come from Laserhub online via automated ordering and order processing. Processing such as CNC laser cutting, folding, powder coating, deburring or bending of sheet metal parts is possible.

Intelligent CNC control for new + old machine tools

Intelligent CNC control for new + old machine tools

“When we went live on the Laserhub.com platform, we primarily had our sights set on orders for CNC laser cutting and sheet metal bending of individual pieces, prototypes and small series. The approach was extremely successful and allowed it to grow extremely quickly. In addition to the number of manufacturers and customers, we have since then continuously increased our scope of services for laser parts or bent parts," says the Laserhub founder Christoph Roessner .

“Now we are ready that we too large series orders can take over. Some companies already cover all of their sheet metal requirements, whether aluminum, Steel or stainless steel, via our platform. At the last Nortec, we are therefore presenting ourselves as a one-stop shop for orders of all sizes. "

Select Gutekunst compression spring, tension spring and leg spring

Select Gutekunst compression spring, tension spring and leg spring

Since 2018, the online shop has brought suppliers and users of the Sheet metal working together and now digitizes and automates the entire job and order management. It brings together the production chain for sheet metal cutting or laser cutting, from the preparation of an offer to production by the appropriate producer and delivery.

Order laser cutting and bent part with a click

Companies can order their laser cut and bent part for laser cutting or sheet metal cutting with just a few clicks. The intelligent platform checks the request within seconds. Each individual customer order is linked to the currently available production resources in the market. There is also a parallel calculation and prices.

The fully automated process checks whether the CAD-Drawings have it manufactured, calculate prices and identify the right producer. Laserhub thus also takes over supplier selection, supplier management for the laser parts online and other sheet metal processing. The manufacturer also ensures that the suppliers produce the blanks in the desired quality and that the laser parts are precisely cut and arrive on the ordered date.

Calculate and order CNC milled and turned parts online

Calculate and order CNC milled and turned parts online

As an automated platform for procurement and order management, Laserhub accelerates the Digitalization the branch Sheet metal working for steel, stainless steel, solid aluminum. In the current times of economic slowdown, in particular, the young company sees an increasing interest in reducing costs, increasing flexibility and utilizing resources.

The full-range supplier for metal parts in the video

How much does an hour of laser cutting cost?

The Costs for an hour laser cutting may vary depending on various factors. Key influencing factors include the type of material being cut, the thickness of the material, the complexity of the desired cutting pattern, and the capability of the laser device. In general, the prices for one hour of laser cutting can be between 50 and 150 euros.

However, it is important to note that this is only a rough guide and that individual offers from service providers may differ. Additional costs may also be incurred for procurement of materials, any preparatory work and post-processing.