as alternative industrial materials

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

as alternative industrial materials

Polymers, elastomers, duroplastics, thermoplastics, polystyrene, etc. extend the service life of your newly developed products.

Image: BASF

Even if Plastic has a rather bad reputation today, so rejoice plastics increasing popularity in industry. Plastics are light, low-maintenance, durable, environmentally friendly and inexpensive. In addition, plastics offer further positive properties compared to other materials, which can also be explicitly generated in their composition. They can be made particularly break-proof, elastic or temperature-resistant. Parts made of plastic are manufactured using the plastic injection molding process.

The Plastics industry is booming and is developing more and more new compositions such as polymers, elastomers, thermosets, thermoplastics, polystyrene and many others - you too can extend the life of your new development with products made of plastic.

Here you will find new developments in plastics technology. Find out about the alternatives material Plastic for your efficient construction!

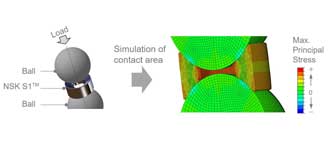

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

NSK presents a world first with the spacer element for ball screws made of 100% bio-based Plastic. Compared to a spacer element made of fossil plastic, the CO2-Footprint by 90% reduced over the entire life cycle. The developers have the bio-based high-performance for thispolyamide Ecopaxx selected by DSM.

Heat is not just heat. Infrared emitters make the difference. This shows an example of the British company Hepworth drainage: The use of infrared emitters here improved a process in plastics processing, in which parts of an inspectiontoolss for ducts made of polypropylene. Various tubes are to be connected to a base unit. Hot glue was used for this in the past. Hepworth was looking for more efficient solutions to save money and protect the environment.

Heat is not just heat. Infrared emitters make the difference. This shows an example of the British company Hepworth drainage: The use of infrared emitters here improved a process in plastics processing, in which parts of an inspectiontoolss for ducts made of polypropylene. Various tubes are to be connected to a base unit. Hot glue was used for this in the past. Hepworth was looking for more efficient solutions to save money and protect the environment.

The division Molding Solutions of the Barnes Group expanded the Foboha technology center for injection molding in Haslach in 2021. The technical center imparts injection molding expertise all year round and is available to customers for tests. In addition, small series can be produced here if necessary and customer events can be held. Included are the grippers and Vacuum Technology from Gimatic.

The division Molding Solutions of the Barnes Group expanded the Foboha technology center for injection molding in Haslach in 2021. The technical center imparts injection molding expertise all year round and is available to customers for tests. In addition, small series can be produced here if necessary and customer events can be held. Included are the grippers and Vacuum Technology from Gimatic.

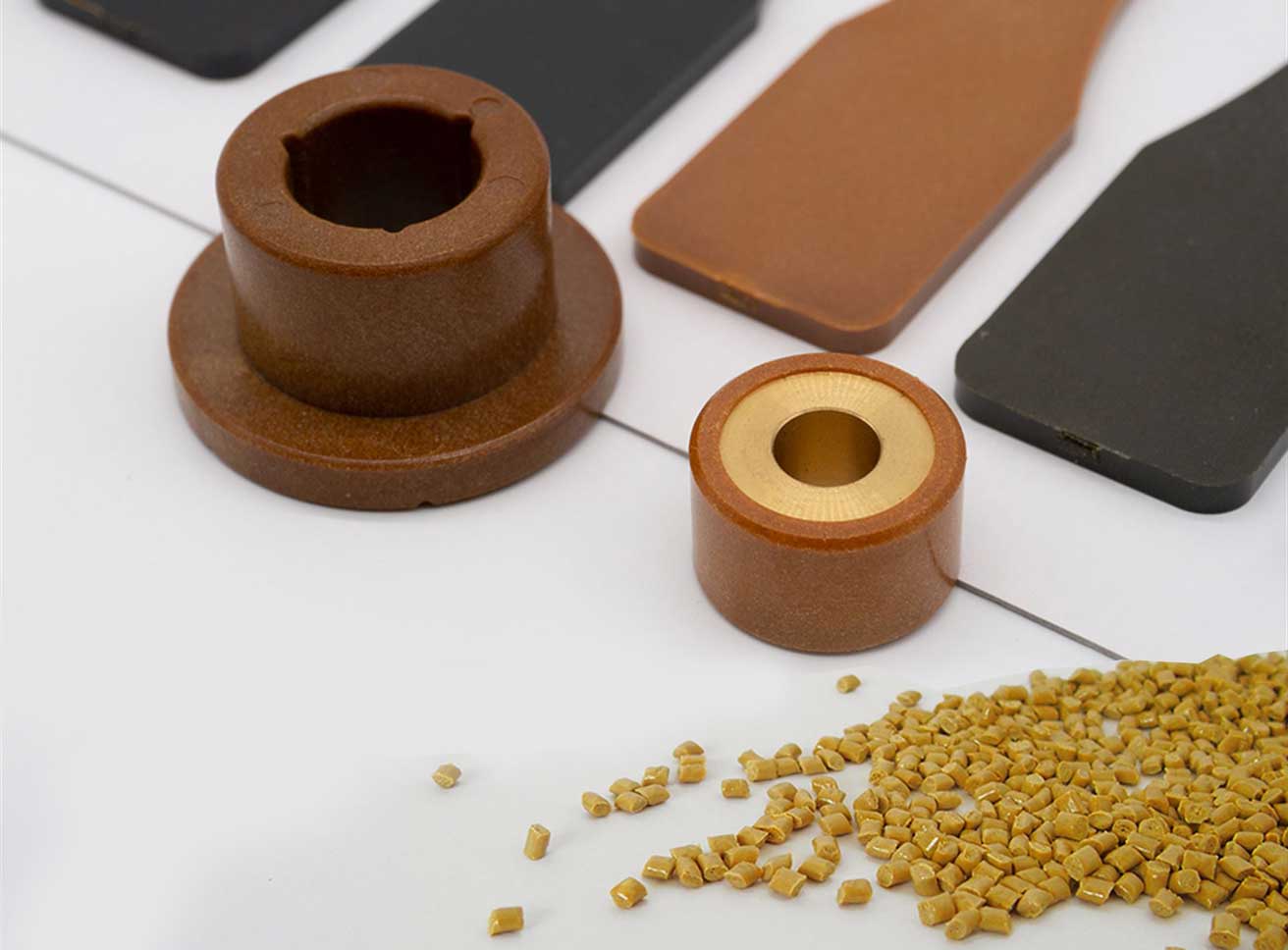

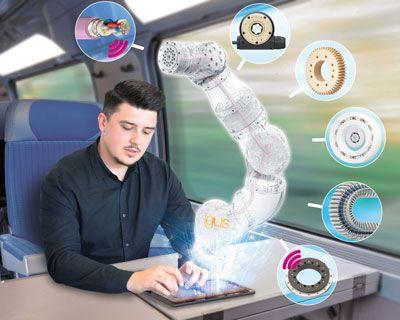

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

When it comes to wear-resistant tribo-polymers, users have Igus the agony of choice. For small series or series production in injection molding, a prototype from the 3D printer or semi-finished products, the plastics specialist has now developed an offline configurator for its 39 Iglidur standard materials: The user can determine the appropriate material using templates. An Iglidur expert system is also available for the selection and calculation of the service life.

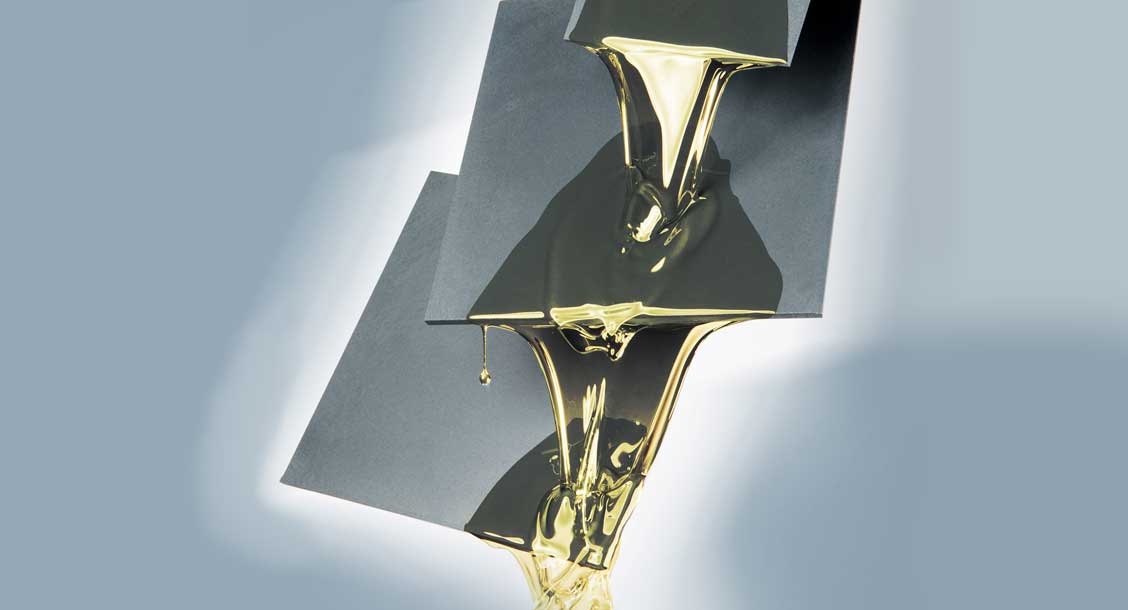

The BASF presents a new one Engineering plasticwho is particularly good Automotive components protects against contact with hot oil. The polyethersulfone (PESU) Ultrasound E0510 C2TR offers very good tribological properties, dimensional stability even under large temperature fluctuations as well high resistance to oil.

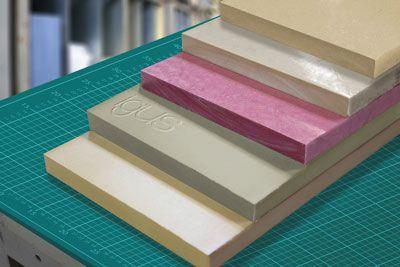

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

So that the user can use even more tribologically optimized special solutions, Igus now has five wear and abrasion-resistant high-performance plastics in its range as semi-finished panel strips. These allow the designer new geometric design freedom.

The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering Plastic with high production efficiency in injection molding. The thermal plastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. As a distributor for PI Meldin from Saint-Gobain, Bieglo presents the PI portfolio, which is also suitable for the 3D pressure suitable.

Because the expected demand quantities are falling in most industries, KVH Hartung presents plastic vacuum deep-drawn parts produced using the negative process as a real alternative to injection molding. The result is housings that cannot be distinguished from the injection molded part when closed.

Because the expected demand quantities are falling in most industries, KVH Hartung presents plastic vacuum deep-drawn parts produced using the negative process as a real alternative to injection molding. The result is housings that cannot be distinguished from the injection molded part when closed.

Configurable online on the tablet, as a long-lasting special edition 3D-printed or equipped with smart intelligence: Motion plastics are developing more and more into high-tech components. This development shows Igus at this year's Hannover Messe with 120 innovations - from intelligent slide bearings to the world's first online platform that brings together providers and users of cost-effective robotics.

Configurable online on the tablet, as a long-lasting special edition 3D-printed or equipped with smart intelligence: Motion plastics are developing more and more into high-tech components. This development shows Igus at this year's Hannover Messe with 120 innovations - from intelligent slide bearings to the world's first online platform that brings together providers and users of cost-effective robotics.

Jihed Marzouki, Junior Key Technology Manager Electro Casting Resins, Rampf Polymer Solutions GmbH & Co. KG, Grafenberg, on the trade fair highlight for tailor-made electro casting resins.

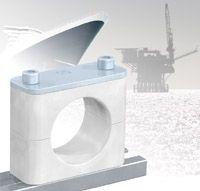

Walter Stauffenberg has developed the material PP-AC for clamp bodies, which considerably delays the formation of crevice corrosion. Pipelines in harsh environments such as on offshore systems are particularly at risk from crevice corrosion. Aggressive salt water penetrates the gap between the pipe and the clamp body and leads to corrosion within this gap.

Walter Stauffenberg has developed the material PP-AC for clamp bodies, which considerably delays the formation of crevice corrosion. Pipelines in harsh environments such as on offshore systems are particularly at risk from crevice corrosion. Aggressive salt water penetrates the gap between the pipe and the clamp body and leads to corrosion within this gap.

The rotary hammer from Dewalt has a plastic housing which, as a combination component, encloses the electric motor and gearbox at the same time. The engineering plastic "Ultradur" B4300 G6 from BASF is used. The demanding component inside the drilling tool replaces two separate housings, one of which - the gearbox housing - was previously made of die-cast magnesium. The plastic housing now encloses the electric motor and the gearbox with chain drive:

The rotary hammer from Dewalt has a plastic housing which, as a combination component, encloses the electric motor and gearbox at the same time. The engineering plastic "Ultradur" B4300 G6 from BASF is used. The demanding component inside the drilling tool replaces two separate housings, one of which - the gearbox housing - was previously made of die-cast magnesium. The plastic housing now encloses the electric motor and the gearbox with chain drive:

Wherever countless pallets, packages or plastic containers have to be transported through the warehouses at high speed over long distances, plastic slide rails are suitable for guiding the roller chains. To transport particularly heavy weights, Faigle now presents new special materials that can withstand even if the previously used UHMW polyethylene fails.

Wherever countless pallets, packages or plastic containers have to be transported through the warehouses at high speed over long distances, plastic slide rails are suitable for guiding the roller chains. To transport particularly heavy weights, Faigle now presents new special materials that can withstand even if the previously used UHMW polyethylene fails.

Sliding elements made of tribopolymers with integrated solid lubricants from Faigle score with low friction and high wear resistance. They can run dry and have good emergency running properties. In addition, they are light in weight, have good corrosion resistance and resistance to chemicals. They run quietly and are not very sensitive to impacts. There are a number of such sliding materials:

Sliding elements made of tribopolymers with integrated solid lubricants from Faigle score with low friction and high wear resistance. They can run dry and have good emergency running properties. In addition, they are light in weight, have good corrosion resistance and resistance to chemicals. They run quietly and are not very sensitive to impacts. There are a number of such sliding materials:

Whether the automotive, energy, automation or household industries: they are all heavily dependent on advances in the storage and transport of electrical energy. As a result, electro casting resins are a key technology driver in these and other industries. Rampf Polymer Solutions presents high-performance silicone, polyurethane and epoxy casting resins with maximum thermal conductivity.

Whether the automotive, energy, automation or household industries: they are all heavily dependent on advances in the storage and transport of electrical energy. As a result, electro casting resins are a key technology driver in these and other industries. Rampf Polymer Solutions presents high-performance silicone, polyurethane and epoxy casting resins with maximum thermal conductivity.

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.

With the new modular microwave technology "Raku Microwave Curing" from Rampf ultra-fast curing and processing times are achieved when mixing and dosing sealing systems, adhesives and potting compounds. The focus is on the thermal activation of one- and two-component plastic systems using microwave radiation.