Polyurethane block material as an alternative to expensive molded panels

- Details

- Hits: 6239

With the highly abrasion-resistant block material "Raku Tool WB-1258" Rampf In numerous foundry model applications, an unbeatable alternative to mold plates and high-priced metals. Thanks to the extremely high abrasion resistance, the polyurethane plate can achieve far more than 100.000 impressions.

With the highly abrasion-resistant block material "Raku Tool WB-1258" Rampf In numerous foundry model applications, an unbeatable alternative to mold plates and high-priced metals. Thanks to the extremely high abrasion resistance, the polyurethane plate can achieve far more than 100.000 impressions.

Until now, this was only possible with liquid systems using complex manufacturing processes at higher costs with high-priced metals such as aluminum. The high-performance block material is used to manufacture core boxes and mold plates, which ensure the quick and easy production of models with good abrasion resistance, dimensional stability and dimensional accuracy.

Milling based on CAD data

The core box or the mold plate is milled directly using CAD data, which guarantees a high level of accuracy of the models. The dimensionally stable polyurethane system can then be easily processed and changes can be made easily. Raku Tool WB-1258 also offers very low sand adhesion and high chemical resistance; there is practically no swelling. Milling tools made from this plate have a very long service life. Color-coordinated adhesives are available.

Liquid resin and epoxy resin for prototypes, models and molds

Liquid resin and epoxy resin for prototypes, models and molds

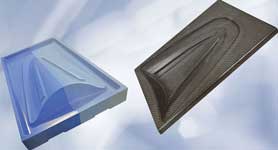

The polyurethane system will henceforth also be available in the USA and officially presented at the Castexpo 2019 in Atlanta. There, the manufacturer also presents two molds, which were made from the model building block material Raku Tool MB-0600 and the tool block material Raku Tool WB-0801.

The polyurethane system Raku Tool MB-0600 offers a fine surface structure, good dimensional stability and a low coefficient of thermal expansion. Applications in the foundry industry include mold plates. The polyurethane system Raku Tool WB-0801 has a fine surface structure and high heat resistance with a low coefficient of thermal expansion. It has very good dimensional stability and good compressive and flexural strength. Applications in the foundry industry include mold plates, core boxes, gauges and fixtures.

3D printing | Additive manufacturing of plastic parts

3D printing | Additive manufacturing of plastic parts

You might also be interested in...

Mineral cast machine bed | produce economically

Reduce carbon footprint | That's how it's done!

Plastic recycling from and for industry and other uses

Industrial liquid gasket, adhesive and potting compound

Mineral cast machine frame for stable six-axis robots