Gluing for gentle joining

Materials, surfaces, methods of application, joining of the parts to be joined, chemical backgrounds, micro-dosing

Image: Rampf

Gluing for gentle joining

Materials, surfaces, methods of application, joining of the parts to be joined, chemical backgrounds, micro-dosing

Image: Rampf

Welding and brazing for industry

MAG welding, MIG welding, TIG welding and ultrasonic welding as well as soldering as a thermal process

Image: Fronius

Connection elements positive and non-positive

Screws and nuts, rivets, springs, threaded rods, washers, wedges, clamps, tolerance sleeves and other standard parts according to DIN, ISO and customer-specific

Image: Heinrich Kipp plant

We'll bring you the latest Connection Technology including force-fitting, form-fitting, substance-to-substance connection technology Glue, detachable connection technology such as screws and other mechanical Fasteners or unsolvable technique like Welding and soldering for all kinds of connections.

Contents

Zu cohesive Connections include soldering and welding. the form-fitting Connection technology can be B. using screws (form fit through thread) and rivets. Screws (positive locking through self-locking) count at the same time non-positive Connection technology, which also includes clamps or wedges. We report on numerous mechanical fasteners or components for connections or attachments in mechanical engineering applications. Electrical connectors like Connectors or clamps, see Electrical Engineering.

The following new developments were made for special Industries like Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery

A classic area of application for the connection technology is the Engineering. While the focus used to be more on connections between metallic materials, these are now being partially replaced by plastics. These make their own demands on the connection technology and can be joined together using laser welding, for example. Read below what's new, whether detachable or non-detachable - a secure hold is guaranteed in any case!

With the so-called traffic light adhesive, it has been possible for the first time to use a color indicator to signal the curing process of an adhesive process using the traffic light colors red, yellow and green. If the use-by date of the new 2-component construction adhesive Scotch-Weld 7270 B / A from 3M is exceeded, the viscoplastic hybrid construction adhesive turns blue.

With the so-called traffic light adhesive, it has been possible for the first time to use a color indicator to signal the curing process of an adhesive process using the traffic light colors red, yellow and green. If the use-by date of the new 2-component construction adhesive Scotch-Weld 7270 B / A from 3M is exceeded, the viscoplastic hybrid construction adhesive turns blue.

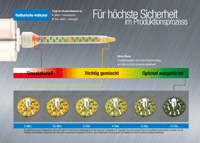

Anaerobic means something like "airless". Anaerobic adhesives are single components or 1K adhesivesthat cure due to the exclusion of air. This is one of the two mechanisms for curing when handling the 1K adhesives. Combined with the second mechanism, contact with metal ions, the material is polymerized quickly - a challenge for the dosing unit. Preflow by Viscotec has one for this Long-term test carried out.