Gluing for gentle joining

Materials, surfaces, methods of application, joining of the parts to be joined, chemical backgrounds, micro-dosing

Image: Rampf

Gluing for gentle joining

Materials, surfaces, methods of application, joining of the parts to be joined, chemical backgrounds, micro-dosing

Image: Rampf

Welding and brazing for industry

MAG welding, MIG welding, TIG welding and ultrasonic welding as well as soldering as a thermal process

Image: Fronius

Connection elements positive and non-positive

Screws and nuts, rivets, springs, threaded rods, washers, wedges, clamps, tolerance sleeves and other standard parts according to DIN, ISO and customer-specific

Image: Heinrich Kipp plant

We'll bring you the latest Connection Technology including force-fitting, form-fitting, substance-to-substance connection technology Glue, detachable connection technology such as screws and other mechanical Fasteners or unsolvable technique like Welding and soldering for all kinds of connections.

Contents

Zu cohesive Connections include soldering and welding. the form-fitting Connection technology can be B. using screws (form fit through thread) and rivets. Screws (positive locking through self-locking) count at the same time non-positive Connection technology, which also includes clamps or wedges. We report on numerous mechanical fasteners or components for connections or attachments in mechanical engineering applications. Electrical connectors like Connectors or clamps, see Electrical Engineering.

The following new developments were made for special Industries like Technical Building Services, Medical Technology, food technology, Microsystems Technology, Mobile Machinery

A classic area of application for the connection technology is the Engineering. While the focus used to be more on connections between metallic materials, these are now being partially replaced by plastics. These make their own demands on the connection technology and can be joined together using laser welding, for example. Read below what's new, whether detachable or non-detachable - a secure hold is guaranteed in any case!

Fronius recently brought the CMT welding process to the company's most modern welding power source, the TPS / i. With the second generation of the cold arc, robot-assisted welding can be carried out in many applications with unprecedented quality, simplicity and process reliability. Because of these advantages, the steel producer and automotive supplier Voestalpine decided to be the first to use the advanced CMT technology in series production.

Fronius recently brought the CMT welding process to the company's most modern welding power source, the TPS / i. With the second generation of the cold arc, robot-assisted welding can be carried out in many applications with unprecedented quality, simplicity and process reliability. Because of these advantages, the steel producer and automotive supplier Voestalpine decided to be the first to use the advanced CMT technology in series production.

Telsonic presents the new control software "Telsoflex" with a new 12 "touch panel for welding and cut-off welding with ultrasound, which makes the ultrasound systems of the USP and TSP series fit for Industry 4.0.

Telsonic presents the new control software "Telsoflex" with a new 12 "touch panel for welding and cut-off welding with ultrasound, which makes the ultrasound systems of the USP and TSP series fit for Industry 4.0.

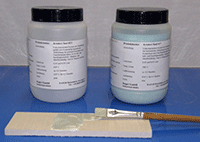

The high-tech adhesives from Kager's Ceramabond range for joining ceramic components withstand extreme conditions of use and high temperatures of up to 1760 ° C. For numerous applications, however, it can make sense to additionally seal and seal the adhesive points with a topcoat. Matched to these cases, Kager offers the matching glass coatings of the "Aremco" family.

The high-tech adhesives from Kager's Ceramabond range for joining ceramic components withstand extreme conditions of use and high temperatures of up to 1760 ° C. For numerous applications, however, it can make sense to additionally seal and seal the adhesive points with a topcoat. Matched to these cases, Kager offers the matching glass coatings of the "Aremco" family.

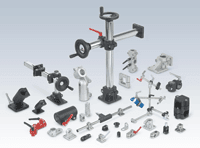

Tube clamp connectors are clamping elements that can be joined together quickly and easily to functional systems using commercially available round or square tubes. Ganter has optimized this product portfolio. All tube clamp connectors are now also available in aluminum.

Tube clamp connectors are clamping elements that can be joined together quickly and easily to functional systems using commercially available round or square tubes. Ganter has optimized this product portfolio. All tube clamp connectors are now also available in aluminum.

For doors and flaps that are to be operated from several positions, Southco has developed the "R4-10 Rotary" latch with double release. It facilitates access when going in or out through a door or to larger access hatches and parts of the appliance when access is from two different points.

For doors and flaps that are to be operated from several positions, Southco has developed the "R4-10 Rotary" latch with double release. It facilitates access when going in or out through a door or to larger access hatches and parts of the appliance when access is from two different points.

Sells through its online shop Misumi a variety of hinge pins and can meet any specific need in this field. Hinge bolts are used in machine and plant engineering and are suitable for precisely rotating bearings, for example for cylinders and cam rollers. A large part of the components can be delivered from batch size 1 within a few days. Hinge pins, also known as hinge pins, belong to the group of machine and fasteners.

Sells through its online shop Misumi a variety of hinge pins and can meet any specific need in this field. Hinge bolts are used in machine and plant engineering and are suitable for precisely rotating bearings, for example for cylinders and cam rollers. A large part of the components can be delivered from batch size 1 within a few days. Hinge pins, also known as hinge pins, belong to the group of machine and fasteners.

The "Parryplug" is a new development from Böllhoff to protect against unauthorized loosening of screw connections. It is used where security is required and aesthetics are required and meets the growing requirements for protection against manipulation and theft in many technical areas.

The "Parryplug" is a new development from Böllhoff to protect against unauthorized loosening of screw connections. It is used where security is required and aesthetics are required and meets the growing requirements for protection against manipulation and theft in many technical areas.

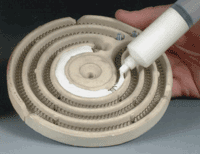

Viscotec has in Preeflow Technical center customer-specific trials for microdosing carried out. The fully automatic production of fiber optic cables became possible using 2K dispenser checked. The customer requested the repeated application of 5 µl of a two-component material in a volumetric mixing ratio of 8,5: 1. The was used Epoxy adhesive EPO TEK353ND.

Will that be Glue from Plastic not permanently strong enough, that often happens Plastic welding used as a joining process. It is used as an alternative, particularly for plastics that are difficult to glue, such as polypropylene PP or polyethylene PE. A welding device or welding machine is used for this. Below we present the New developments for the thermal joining process as well as for plastic welding with laser or ultrasound.

Modern ceramic-based adhesives create connections that hold securely even under extreme operating conditions. The high-tech adhesive Ceramabond 890, which Kager recently added to its wide range of adhesives, is specially designed for the material pairings ceramic-ceramic and ceramic-graphite. This 1K silicon carbide adhesive can be used to create chemically and mechanically resilient high-temperature connections.

Modern ceramic-based adhesives create connections that hold securely even under extreme operating conditions. The high-tech adhesive Ceramabond 890, which Kager recently added to its wide range of adhesives, is specially designed for the material pairings ceramic-ceramic and ceramic-graphite. This 1K silicon carbide adhesive can be used to create chemically and mechanically resilient high-temperature connections.

Bormann + Neupert and + HCL Fasteners present their nylon hose clamps “Herbie Clips” and nylon straps “Smart-Band” as well as other tie-in systems. Fastening solutions made of plastic offer several advantages. The Herbie clips ensure the tightness of hose and pipe connections in systems and machines of all sizes at operating pressures of up to 14 bar.

Bormann + Neupert and + HCL Fasteners present their nylon hose clamps “Herbie Clips” and nylon straps “Smart-Band” as well as other tie-in systems. Fastening solutions made of plastic offer several advantages. The Herbie clips ensure the tightness of hose and pipe connections in systems and machines of all sizes at operating pressures of up to 14 bar.