Plastic welding | New products, processes, accessories

- Details

- Hits: 13826

Will that be Glue from Plastic not permanently strong enough, that often happens Plastic welding used as a joining process. It is used as an alternative, particularly for plastics that are difficult to glue, such as polypropylene PP or polyethylene PE. A welding device or welding machine is used for this. Below we present the New developments for the thermal joining process as well as for plastic welding with laser or ultrasound.

Contents

- Modules for laser plastic welding

- Universal machine for plastic welding with laser

- Welding plastics: common techniques

Modules for laser plastic welding

06.08.2021: Machines that are suitable for fully automated industrial production are required, especially when manufacturing large quantities. Evosys offers efficient systems for this, especially for laser plastic welding. The devices and machines for that thermoplastic welding processes are compact and can be easily integrated into modern production systems. One example are the new pre-calibrated laser modules EVO 0550 and EVO 0750 with laser control.

06.08.2021: Machines that are suitable for fully automated industrial production are required, especially when manufacturing large quantities. Evosys offers efficient systems for this, especially for laser plastic welding. The devices and machines for that thermoplastic welding processes are compact and can be easily integrated into modern production systems. One example are the new pre-calibrated laser modules EVO 0550 and EVO 0750 with laser control.

The modules for plastic welding are interchangeable worldwide and easy to use in the welding process Plug-and-play capable transferable. The modules are also available with suitable process monitoring. Evosys also supports the user with initial setup in production.

The integration solutions guarantee Laser class 1 and a stable welding process. Comprehensive interfaces and options for process monitoring complete the modules for plastic welding.

Optimize weld seam with calculation and profile measurement

Optimize weld seam with calculation and profile measurement

The flexible laser module EVO 0550 with fixed optics and that EVO 0750 Module with scanner for laser welding of plastics can be easily integrated into automation lines and allow efficient project planning. Thanks to their space-saving design, they fit into almost any production environment.

Evosys is exhibiting at Fakuma 2021.

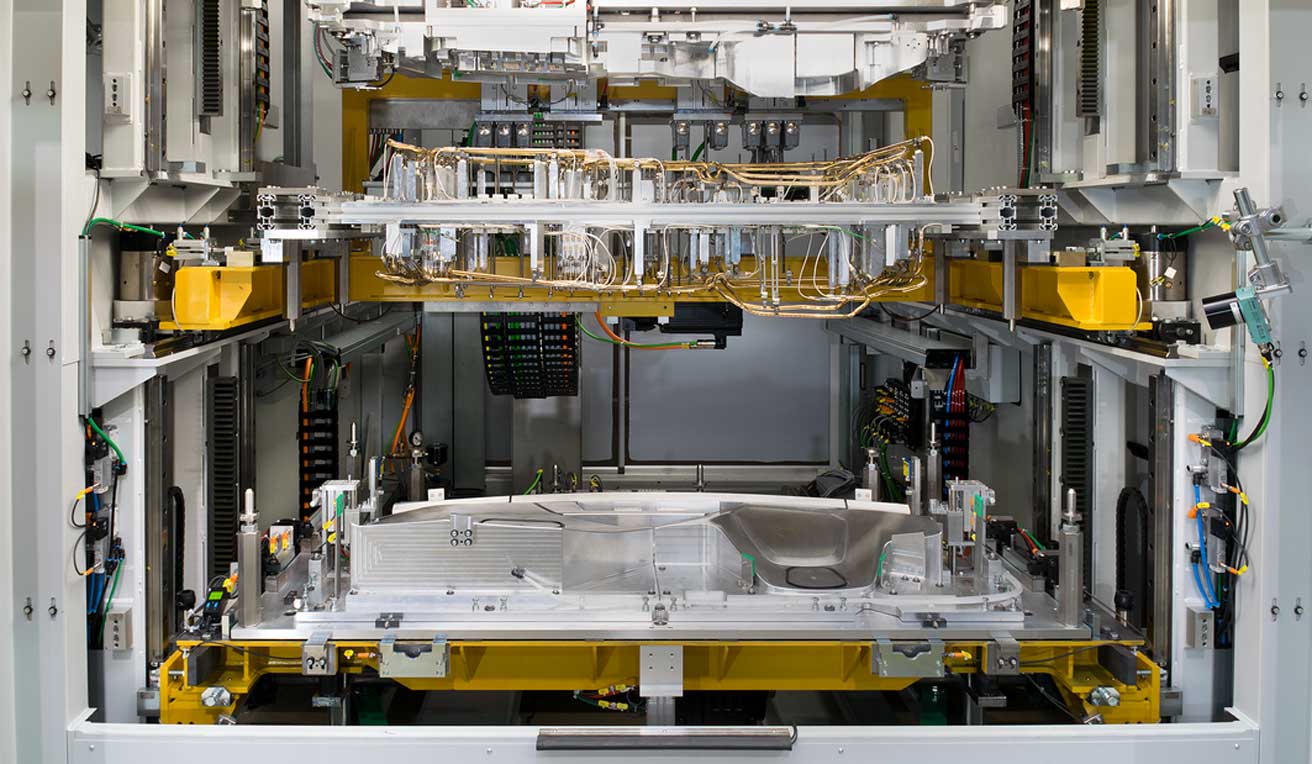

Universal machine for plastic welding with laser

06.08.2021: The Evoweld from Evosys is a universal machine for laser plastic welding. It is particularly suitable for processing small and medium-sized series. The plastic welding machine can be tailored to the application in terms of the laser source and optical modules. It offers a wide range of possible uses. With a footprint of approx. 1 m², the machine for thermoplastic welding fits into any production environment.

06.08.2021: The Evoweld from Evosys is a universal machine for laser plastic welding. It is particularly suitable for processing small and medium-sized series. The plastic welding machine can be tailored to the application in terms of the laser source and optical modules. It offers a wide range of possible uses. With a footprint of approx. 1 m², the machine for thermoplastic welding fits into any production environment.

A user-friendly one Human machine interface (HMI) and the intuitive process software ensure convenient operation. Almost maintenance-free and service-friendly, the welding machine for plastics is suitable for use in 24/7 production. The Evoweld runs through the unique CQC calibration concept of Evosys Laser GmbH, which ensures the comparability of systems.

So that the quality is also guaranteed during production, the machine for plastic welding is available with different Online monitoring modules. The compact machine is housed in a standard housing in which all components such as the laser, control unit and rotary indexing table are integrated. Laser welding of plastics is widespread in many applications today because this welding process is economical and offers high system availability.

Evosys is exhibiting at Fakuma 2021.

Common techniques for welding plastics

18.02.2018: The Plastic welding machines from KLN offer solutions for practically all common Connection techniques for plastics. The focus is on Ultrasonic welding, Vibration welding, heating element, infrared and spin welding. There are also laser welding and thermal processes such as hot air and hot riveting.

The range of the industrial cleaning technology ranges from ultrasonic through-feed special systems and spray systems to solvent systems and modular systems. It includes ultrasonic oscillating tanks through to components such as dryer systems, generators and ultrasonic oscillating plates.

PVC and other coatings for the automotive industry

PVC and other coatings for the automotive industry

With an investment volume of 6 million euros for the new construction of Plant II, the company will expand the capacity and flexibility of customer-specific production. For Dominik Rau, Head of Operations, means the implementation of shorter lead times. Development and manufacturing processes are accelerated further without endangering the high product quality.

The use of state-of-the-art manufacturing equipment and methods, including through our own Laser cutting and painting system, by having its own tool shop promotes flexibility and at the same time lowers production costs. The company is at home in many industries such as plastics technology, Automotive, mechanical and plant engineering, Medical Technology and packaging technology, Tools, Energy and solar technology, Electroplating and the electronics industry.