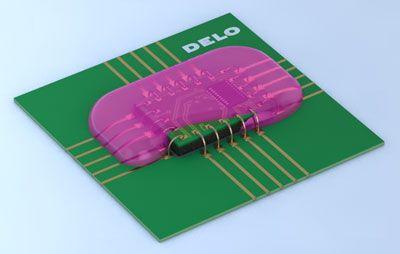

Delo has a potting compound developed which has a very high media and temperature resistance. In addition, “Monopox GE6515” accelerates manufacturing processes thanks to its optimized curing time. The product is particularly suitable for potting electronic components for automotive applications.

Delo has a potting compound developed which has a very high media and temperature resistance. In addition, “Monopox GE6515” accelerates manufacturing processes thanks to its optimized curing time. The product is particularly suitable for potting electronic components for automotive applications.

Monopox GE6515 is a one-component, all-thermosetting epoxy resin. The potting compound achieves a very high strength even at high temperatures. On aluminum and at 150 ° C this is at 20 MPa; in the upper temperature range of 200 ° C it is still 14 MPa.

Liquid resin and epoxy resin for prototypes, models and molds

Liquid resin and epoxy resin for prototypes, models and molds

The product also adheres very well to materials such as FR4, FA and copper and was developed especially for the casting of electronic components. Also, the adhesive has a high resistance to chemicals such as oils, acids or fuels.

The potting compound also has a material that is adapted to the materials usually used in the automotive sector Coefficient of thermal expansion (CTE). This is up to the glass transition temperature (Tg) of 155 ° C at 23 ppm / K and above Tg at 48 ppm / K. A low CTE is particularly necessary for applications in which distortion under the influence of temperature is to be avoided.

Wago Gelbox protects connection terminals from moisture

Wago Gelbox protects connection terminals from moisture

The curing of the potting compound takes place in a circulating air oven at temperatures between + 90 ° C and + 150 ° C. At 130 ° C, the epoxy resin is already fully cured after 15 min, which can accelerate manufacturing processes. The processing time is one week.