for construction & development

Simulation, analysis, optimization or validation, DMU, FEM, CFD, MKS, CAQ and CAM as well as fluid or flow simulation

Image: Dualis

for construction & development

Simulation, analysis, optimization or validation, DMU, FEM, CFD, MKS, CAQ and CAM as well as fluid or flow simulation

Image: Dualis

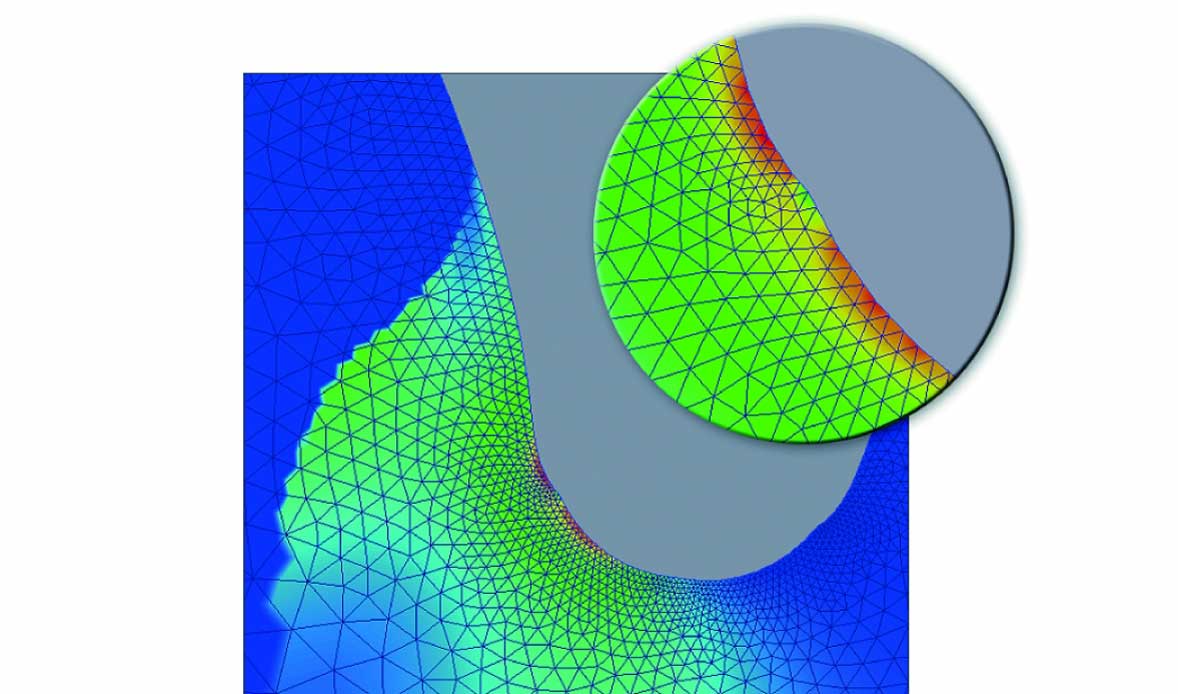

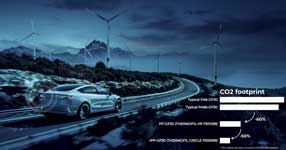

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

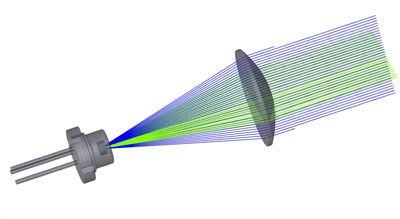

Imos Gubela has many years of experience in the development of high-precision optical systems. The company simulates and produces high-precision optical systems with plastic lenses from prototypes to series production. The optics specialist relies on a simulation tool that takes into account the material and production-related tolerances.

Imos Gubela has many years of experience in the development of high-precision optical systems. The company simulates and produces high-precision optical systems with plastic lenses from prototypes to series production. The optics specialist relies on a simulation tool that takes into account the material and production-related tolerances.

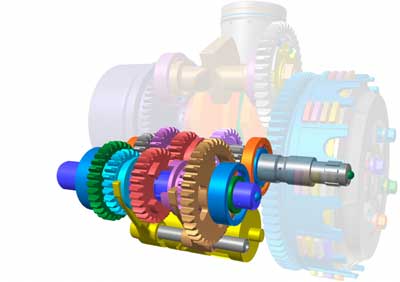

function bay and KISSsoft present one simulation software or two toolkits that simulate the dynamic behavior of gearboxes can be improved. With such optimization, designers are meeting today's requirements for reducing Noises and vibrations in gearbox and drive train.

function bay and KISSsoft present one simulation software or two toolkits that simulate the dynamic behavior of gearboxes can be improved. With such optimization, designers are meeting today's requirements for reducing Noises and vibrations in gearbox and drive train.