for construction & development

Simulation, analysis, optimization or validation, DMU, FEM, CFD, MKS, CAQ and CAM as well as fluid or flow simulation

Image: Dualis

for construction & development

Simulation, analysis, optimization or validation, DMU, FEM, CFD, MKS, CAQ and CAM as well as fluid or flow simulation

Image: Dualis

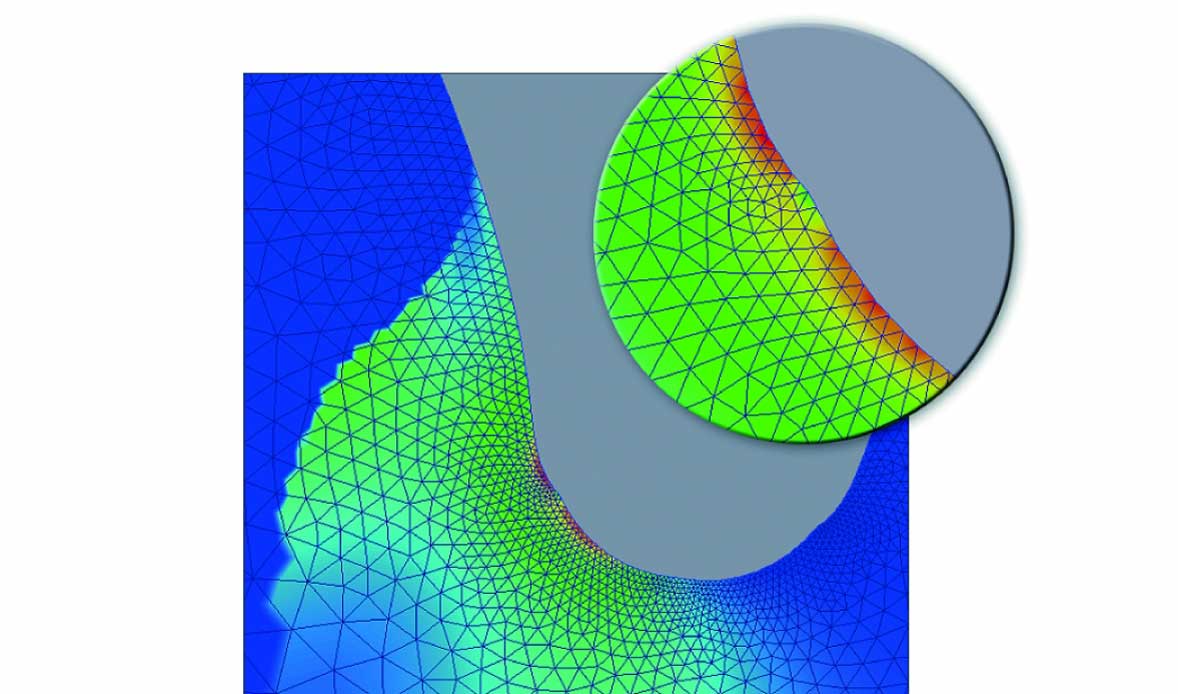

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

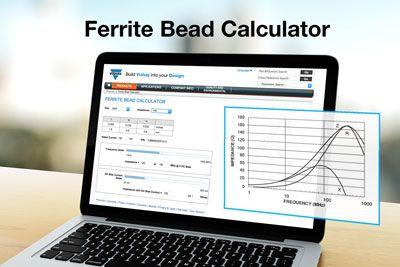

Vishay Intertechnology introduces the world's first tool for calculating the impedance of ferrite beads. The online calculator makes it quick and easy to calculate the impedance of Vishay's most popular ferrite beads at a given frequency and DC bias current.

Vishay Intertechnology introduces the world's first tool for calculating the impedance of ferrite beads. The online calculator makes it quick and easy to calculate the impedance of Vishay's most popular ferrite beads at a given frequency and DC bias current.

As a support for designers and developers, Ejot offers forecast programs for the pre-design of direct screw connections. With these tools, screw connection parameters can be calculated depending on materials and construction parameters. Numerous practical examples show that these programs can already achieve significant savings during the development phase. The new "Altra Calc" program was specially developed for predicting direct screw connections in light metals.

As a support for designers and developers, Ejot offers forecast programs for the pre-design of direct screw connections. With these tools, screw connection parameters can be calculated depending on materials and construction parameters. Numerous practical examples show that these programs can already achieve significant savings during the development phase. The new "Altra Calc" program was specially developed for predicting direct screw connections in light metals.

Forming Technologies (FTI) provides for online Sheet metal processing new functionalities for the virtual manufacturing in front. With the Forming suite Software enables the process simulation for sheet metal forming to be implemented more efficiently. CAD interoperability and Hexagon-3D scans. The forming suite enables manufacturers to better estimate the tool and material costs in sheet metal processing and to assess the design implementation.

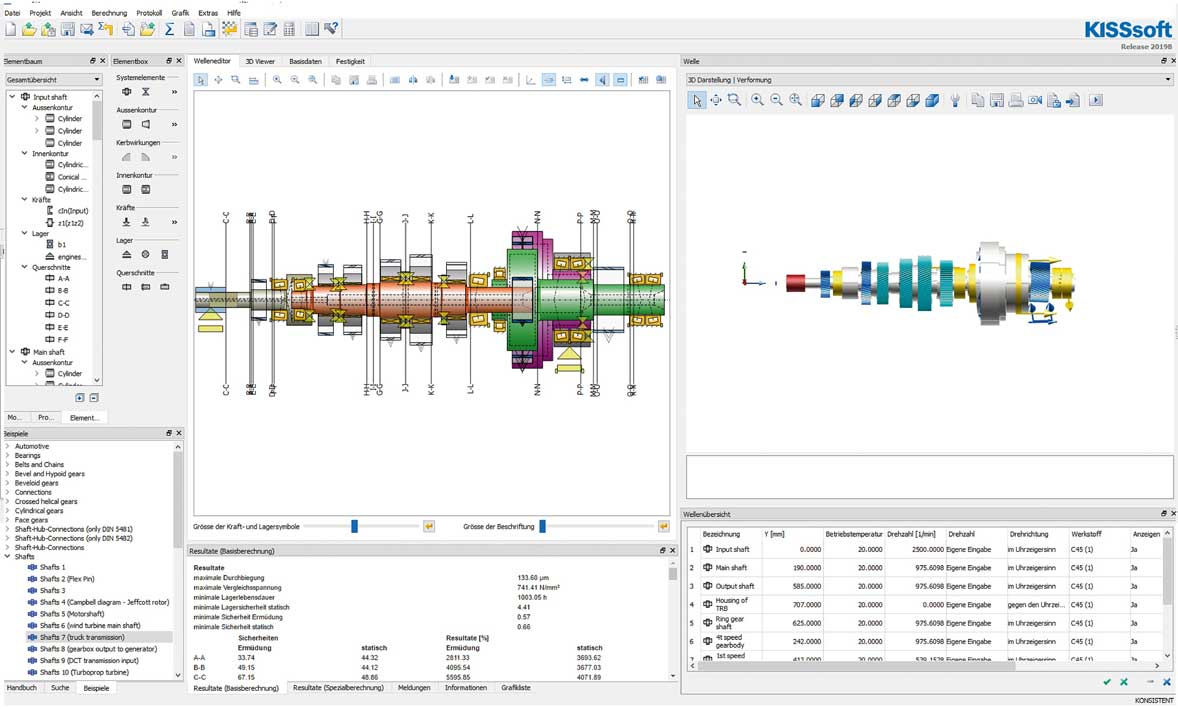

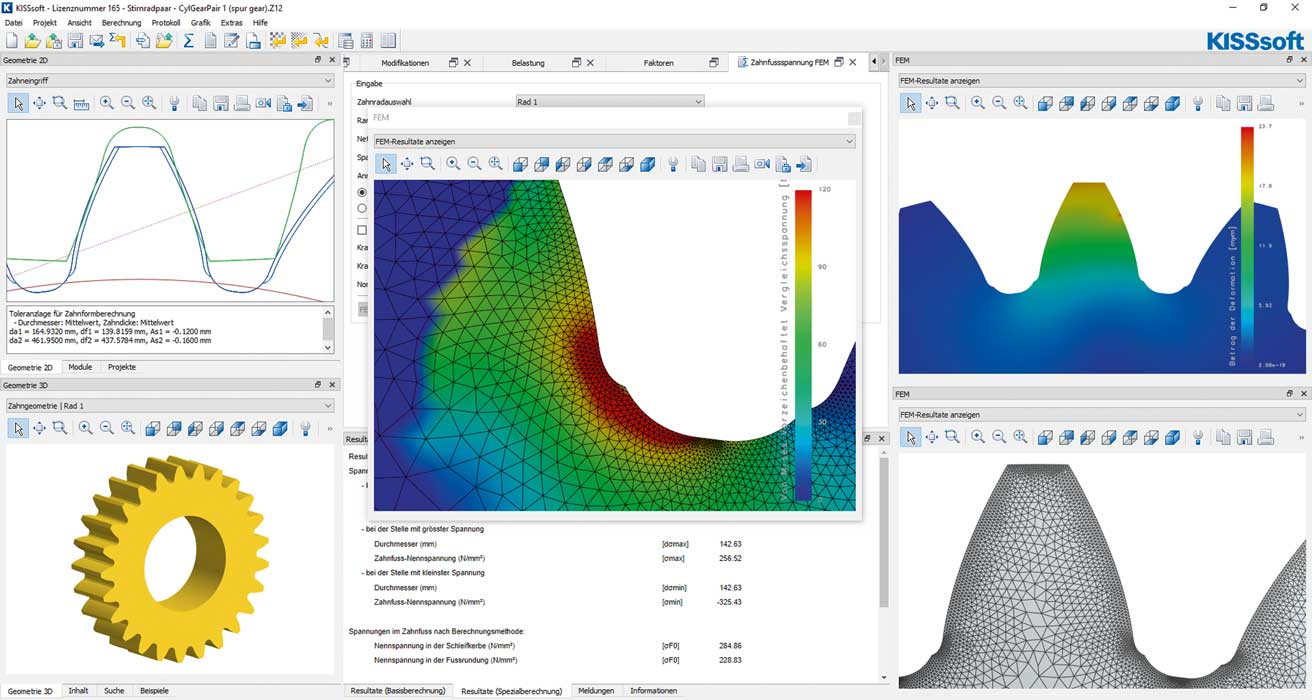

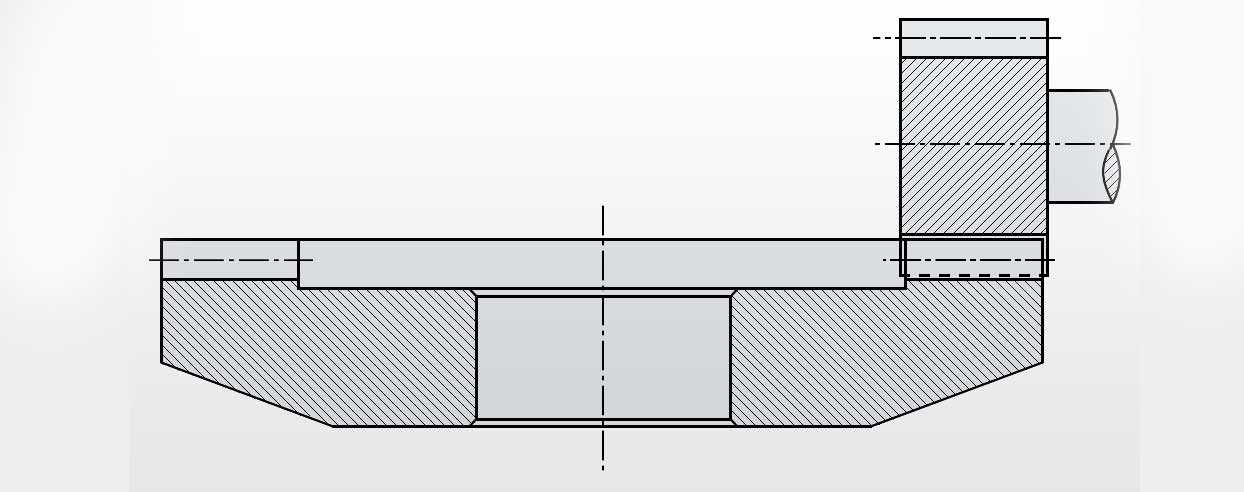

As part of their cooperation SKF and KISSsoft a new interface to the Bearing calculation created which the Gear construction Simplified: This enables the engineers to find the ones that are suitable for the machine design Warehouse based on cutting-edge storage technologies.

If the designer designs a new machine, he has to use the individual ones Machine Elements dimension. There are two concepts for analyzing it. FEM as the finite element method or the Machine elements method or the analytical or standardized method. In KISSsoft the developer finds a combination of both.

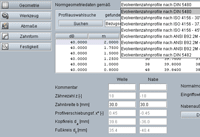

GWJ Technology provides an extensively expanded version of the calculation module for splined shaft connections within their web-based software gear calculation for gear transmission "eAssistant" in front. So far, the calculation of splines was supported by DIN 5480. In addition, an individual geometry definition is possible. The calculation for splined shaft connections according to ISO and ANSI 4156 B92.2 is now integrated.

GWJ Technology provides an extensively expanded version of the calculation module for splined shaft connections within their web-based software gear calculation for gear transmission "eAssistant" in front. So far, the calculation of splines was supported by DIN 5480. In addition, an individual geometry definition is possible. The calculation for splined shaft connections according to ISO and ANSI 4156 B92.2 is now integrated.

The WB4 module is now available for bearing calculation in Kisssoft: This enables the individual bearings to be calculated directly using the ISO 16281 method, taking into account the internal geometry, without the forces having to be determined in advance in the shaft editor. Actual storage situations and more are taken into account.

The WB4 module is now available for bearing calculation in Kisssoft: This enables the individual bearings to be calculated directly using the ISO 16281 method, taking into account the internal geometry, without the forces having to be determined in advance in the shaft editor. Actual storage situations and more are taken into account.

PTC's Creo Flow Analysis Extension is a Computational Fluid Dynamics (CFD) solution that allows designers, engineers, and analysts to directly simulate fluid flow problems in Creo. The seamless workflow between CAD and CFD enables users to integrate the analysis early and often to understand product function and performance. The software was specially developed for the designer.

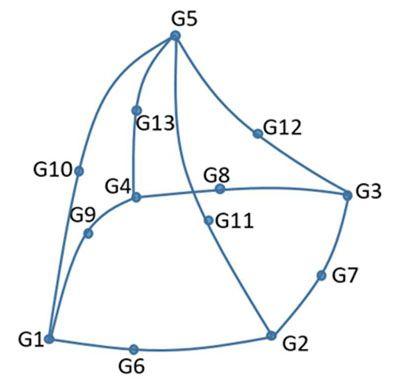

To meet the growing demand for Crown gear Has to face calculation GWJ a Calculation module for bevel gears, consisting of face gears paired with cylindrical Spur gears in program. This module for angular gears is an extension option for the standard calculation solutions e-Assistant and TBK 2014.

The first free iPhone app from Kisssoft for hardness conversion is now available. With this iPhone application, the conversion of hardness values according to the hardness test methods according to Vickers, Brinell and Rockwell can now easily be carried out on the go. For this purpose, only one value has to be entered - the remaining hardness values are calculated immediately. The user can also compare different hardness scales with one another. Information on the individual test procedures round off this handy and effective iPhone app.

The first free iPhone app from Kisssoft for hardness conversion is now available. With this iPhone application, the conversion of hardness values according to the hardness test methods according to Vickers, Brinell and Rockwell can now easily be carried out on the go. For this purpose, only one value has to be entered - the remaining hardness values are calculated immediately. The user can also compare different hardness scales with one another. Information on the individual test procedures round off this handy and effective iPhone app.

MSC Software announces the release of the new version MSC Nastran 2019.0. MSC Nastran is the most frequently used finite element (FE) solver worldwide for structural analyzes in the areas of statics, dynamics and acoustics. Version 2019.0 offers new element types and more user-friendliness when modeling loads and contacts.

MSC Software announces the release of the new version MSC Nastran 2019.0. MSC Nastran is the most frequently used finite element (FE) solver worldwide for structural analyzes in the areas of statics, dynamics and acoustics. Version 2019.0 offers new element types and more user-friendliness when modeling loads and contacts.

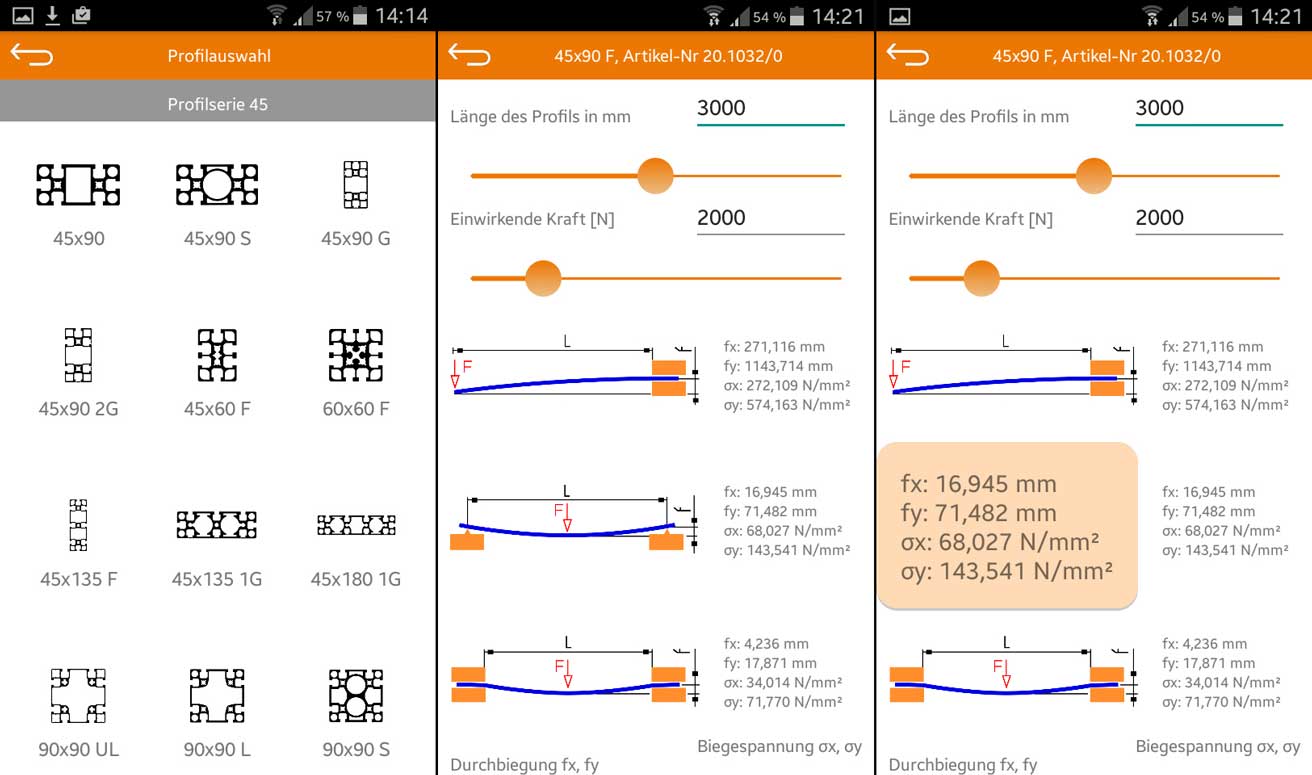

A App from Minitec design engineers, equipment builders and production planners can easily use their smartphones to do the load-dependent Calculate deflection. The app calculates the deflection based on the aluminum profiles and linear axes from the modular system of the system provider. This enables you to quickly determine whether the profiles and axes of the static and punctiform loading are correctly dimensioned in a specific case - or not.