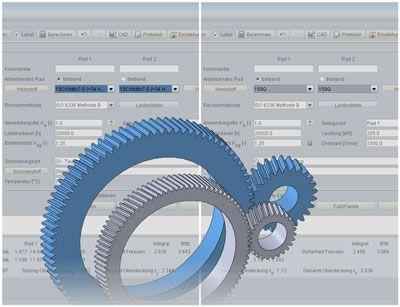

GWJ Technology integrated as the world's first manufacturer of professional calculation software for gear transmission high-purity steels from Ovako from Sweden. In close cooperation, the two high-purity steels 159X and 159Q were implemented in the gear modules for spur gears. They are based on case hardening steel 18CrNiMo7-6.

GWJ Technology integrated as the world's first manufacturer of professional calculation software for gear transmission high-purity steels from Ovako from Sweden. In close cooperation, the two high-purity steels 159X and 159Q were implemented in the gear modules for spur gears. They are based on case hardening steel 18CrNiMo7-6.

Due to significantly lower impurities, these steels have modified Wöhler curves. This makes them comparable to the 18CrNiMo7-6 in the static area. In the fatigue range, however, 159Q offers approximately 30% higher flanking capacity and 60% higher tooth base strength. These higher fatigue strength values are based on Ovako internal investigations and have been verified by investigations at the WZL in Aachen and at the FZG in Munich.

Der Stahl 159X weist eine etwas kleinere Leistungssteigerung gegenüber dem 18CrNiMo7-6 auf und eignet sich damit u. a. gut bei notwendiger Verbesserung bereits bestehender Konstruktionen. Das Potential des 159Q lässt sich besonders bei Neuauslegungen nutzen. Dabei kann es von Vorteil sein, den Fokus mit auf eine optimierte Fresstragfähigkeit zu legen. Dadurch ergeben sich in der Regel bessere Verzahnungswirkungsgrade und somit geringere Verlustleistungen. Aus Sicht von GWJ Technology eröffnen diese Ovako-Stähle komplett neue Möglichkeiten für Getriebe und besitzen ein hohes Potential zur weiteren Leistungssteigerung von Geargetrieben und Verzahnungskomponenten.

Efficient gear wheel perspectives made of high-performance plastic

Efficient gear wheel perspectives made of high-performance plastic

The two steels 159X and 159Q are available in all three GWJ software solutions for gear calculation, ie in the web solution "Eassistant", in the desktop application TBK and in the special software "Gear Engineer" for 5 gear cutting.

You might also be interested in...

Universally applicable intelligent CAQ system