Integrated tools and services for digital engineering

- Details

- Hits: 5894

The digital transformation lives from the closer connection of the available data - not only in the current production, but already in the development of machines and systems. Lenze zWhat data the company makes available to its partners and how it can be integrated and used advantageously. Only the right tools, services and methods make this possible machine builders the successful entry into Digital engineering.

The switch from construction drawings on paper to the electronic counterpart was an important step on the way to digitalization. The Digital transformation now stands for the next evolutionary step: The data from the sensor and drive moves into the development of the module, from there to the design of machines and systems and can later also be used during ongoing operations as well as for maintenance, services and retrofitting.

The promising concept on which this lifelong data flow can be based is called a somewhat bulky "administrative shell" - in the international usage Asset Administration Shell (AAS). It is already a core component in the reference architecture model Industry 4.0 (Rami 4.0).

No industry 4.0 without AAS

It could also be called a container in which the relevant data is collected for each asset: description of the mechanical-electrical properties, documentation and certificates, software, behavioral description and much more. This information pool serves as the basis for the Industry 4.0 applications and must therefore follow certain standards to meet universal requirements.

Aucotec opens the gate to the 3rd dimension in Engineering Base

Aucotec opens the gate to the 3rd dimension in Engineering Base

Although the concept was adopted by the Industry 4.0 platform more than three years ago, many questions remain unsolved. But slowly the gaps close, which prevent the continuous data use so far. Lenze also contributes to this: working in standardization committees, with white papers and experts who support customers in digital engineering - and with its tools and apps that already make the AAS concept applicable today.

Planning the system solution

One of the central tools of the drive specialist for digital engineering is the Easy System Designer. In the near future, this web-based planning tool will support the user in the complete planning of machine solutions consisting of automation and drive components as well as software. Based on the extensive integrated automation knowledge, the tool checks the developed system solution with regard to its feasibility and documents everything necessary for those involved in the engineering process. This saves valuable planning time, shortens the decision-making process and reduces the risks in the project. Consistency creates added value: The solution is available for further tasks in engineering. The total solution can be immediately transferred to the cart of the Easy Product Finder to speed up the quotation process.

Solidworks 2022 | CAD software by and for users

Solidworks 2022 | CAD software by and for users

It is then possible to prepare a PLC program based on the planned system solution. The machine structure, selected hardware components and software modules as well as the application parameters and other relevant project data are available to the programmer in his engineering environment. This enables him to finalize the PLC program and get the machine up and running much faster. The Asset Administration Shell is filled in parallel to this process: it is processed further with all tools that know and understand the structure of the AAS.

Virtual and real world united

The fact that the AAS can not only be a theoretical concept but a real support in industrial automation is already demonstrated by Lenze in the live operation of a picker cell at the exhibition stand. Similar to the Rami 4.0, in addition to the type information, the AAS also provides information of the real instance such as serial number and date of manufacture, but also live data. The standardization and structuring of the data as well as the central linkage as "point of truth", over which all necessary information is available, are advantageous for OEMs as well as for plant operators. Because every media disruption carries the risk that information is passed on incorrectly, outdated or simply not available.

On the other hand, in-depth information can be obtained from comprehensive data availability without having to install additional measuring points. How effective condition monitoring can be built from the data of the components paired with application know-how and suitable analysis tools is also part of a show case.

Close to the market

At SPS, Lenze will be presenting tools, prototypes and concept studies for digital engineering to show its partners what the development departments will be able to rely on in the future. At the same time, users are encouraged to give feedback and formulate their requirements. Thus, the development of the tools can be closely aligned to the market. The company is thus proving to be a solution provider for the 4.0 and IIoT industry, taking on a leading role in digitizing the industry.

Another contribution of the manufacturer

You might also be interested in...

CAD automation creates freedom for the designer

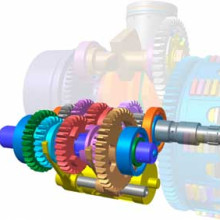

Simulation software for the behavior of the transmission and drive train

CAD data found faster in manufacturer catalogs 2019