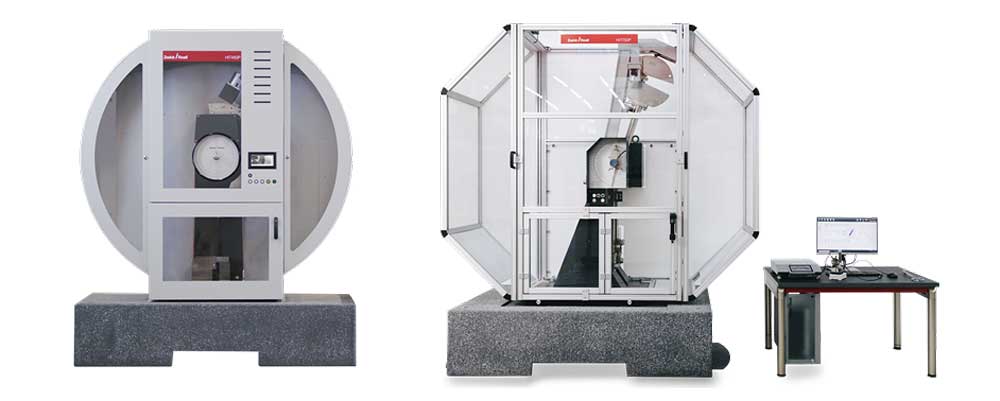

Pendulum impact tester for the notched impact test on metals

- Details

- Hits: 6010

The Notched bar impact test is a process of Materials testing with which the toughness of materials can be determined comparatively quickly and with little effort. With the new Pendulum HIT450P for the impact test on metals Zwick Roell a device that was optimally tailored to the experiment.

This is how the impact test goes

The notched-bar impact test is a material testing method in which a Material sample in the form of an elongated cuboid - notched on one side and usually tempered - is tested under impact stress. A pendulum hammer hits the unnotched back of the sample and shatters it. The sample absorbs part of the kinetic energy transferred during the deformation process, so that the pendulum hammer swings less high on the opposite side. This energy loss is used to determine the impact energy for a specific material at specific temperatures. In addition to the notched impact work, the notched impact strength of the materials can also be determined.

The basic device of the pendulum hammer can be adapted to a wide range of options for a wide variety of applications. The ergonomic design and the logical user guidance via the test software "Testxpert III" ensure safe and precise tests. The input options for the operator can be reduced to a minimum.

FAQ

What is a notched bar impact test?

The notched bar impact test is a Procedure for material testing, with which the toughness properties and in particular the notched impact strength of materials are determined according to certain standards such as DIN EN 10045, DIN EN ISO 148-1 and DIN EN ISO 179-1.

What does Charpy impact test mean?

The notched-bar impact test according to Charpy is a standardized proceduren to determine the toughness of a material, particularly its ability to absorb energy under impact loading. It is widely used for assessing material toughness, especially for metals, due to its ease of implementation and reliable results. In this test, a standardized sample is scored and then subjected to an impact at a specified temperature by striking the opposite side of the score with a pendulum hammer. The energy absorbed by the pendulum when the sample breaks is measured and given as a measure of the notched impact strength of the material.

What describes notched impact work?

The Impact work W is a measure of the energy a material can absorb before it breaks when subjected to a sudden blow or shock. It is typically determined by notched impact bending tests, in which a standardized sample with a notch is subjected to an impact. The notched impact energy provides information about the toughness of the material, i.e. its ability to withstand shock loads without breaking.

What does the notch in the sample symbolize in terms of technique?

In impact work, there are two main types of notches used in the specimens: the U-notch and the V-notch. The choice of notch shape depends on the properties of the material being tested and the purpose of the test. Each notch shape provides different insights into how the material behaves under impact loads. The notch shapes influence how the stress is distributed in the sample during the notch impact test:

The U-notch (or round notch) has a semicircular or U-shaped cross section and causes a more even distribution of stress. It is less concentrated than the V-notch and is often used to test the toughness of more ductile materials.

The V-notch has a V-shaped cross section and concentrates the stress more at one point, resulting in a higher stress concentration at the notch tip. The V-notch is often used to test more brittle materials because it represents a harsher testing condition and better demonstrates the material's tendency to fracture brittlely.

You might also be interested in...

Universally applicable intelligent CAQ system

Green hydrogen on the advance in Germany

industrial robots | The production employees

Measure solar radiation and determine UV Eruthem radiation

Learn everything about infrared camera measurement technology at Optris

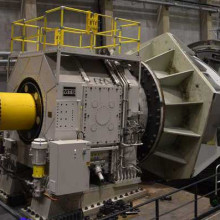

Large wind turbine successfully tested on a system test bench

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.