Hall sensor increases process reliability in magnetic stirrers at AWH

- Details

- Hits: 7985

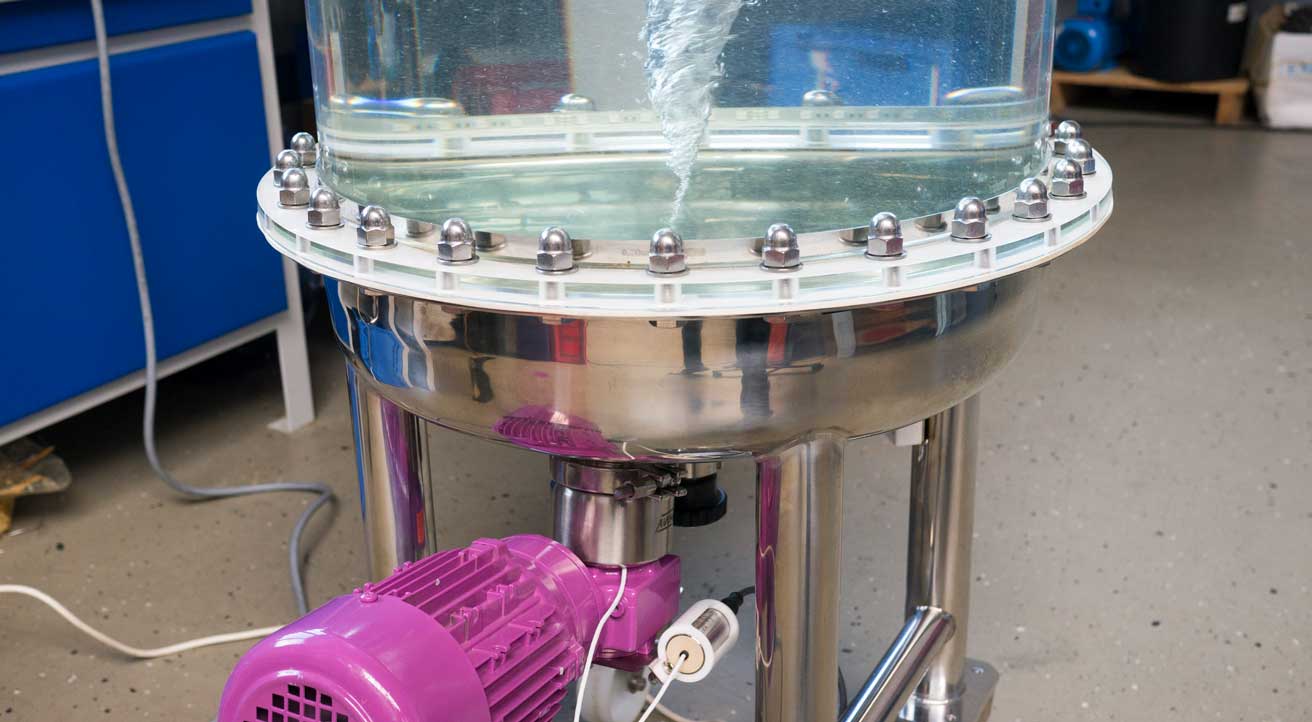

Was looking to record the speed of his Vpuremix magnetic stirrers Awh for a compact solution for all sizes of the device series. Developed especially for this task Turck an Hall Sensorwhich detects the exact speed of the mixing head in the container through the stainless steel wall. Thanks to a double execution Hall probe the magnetic field sensor also detects the direction in which the mixing heads are moving. In this way, AWH increases the safety of its agitator processes with just one type of sensor.

Contents

- Who is AWH?

- Speed sensor for magnetic agitators

- A Hall effect sensor for all magnetic agitators

- Frequently asked questions?

Who is AWH?

The company has a very varied history Armaturenwerk Hötensleben GmbH in Saxony-Anhalt. The entire recent German history can be read from its milestones from 1859 to the present day. The company originally began as a metal foundry, and has been manufacturing stainless steel components such as valves, fittings and connectors since 1992.

The company has a very varied history Armaturenwerk Hötensleben GmbH in Saxony-Anhalt. The entire recent German history can be read from its milestones from 1859 to the present day. The company originally began as a metal foundry, and has been manufacturing stainless steel components such as valves, fittings and connectors since 1992.

2003 came first Cleaning technology and later the Pigging technology added. For a short time, AWH has also been offering its customers magnetic stirrers with the Vpuremix series. The magnetic stirrers, optimized for process reliability and sterility, are used in particular in the pharmaceutical, biotech and Food industry Commitment. The users homogenize or suspend liquid media gently and efficiently, use them for heat exchange or concentration compensation.

Speed sensor for magnetic agitators

"In order to determine the stirrer performance, we need information about the speed of the mixing head, among other things," explains AWH product manager Anya Hauffe. This feature is known in the industry as a speed sensor. In particular, when different speeds are run within a production batch, speed detection on the agitator is required. This feature is therefore mandatory for most customers.

Most compact Atex pressure switch in its class for hydraulics

Most compact Atex pressure switch in its class for hydraulics

The mixing head is driven contactlessly through the container wall via magnets. So it made sense to use the magnetic field to determine the speed. “We needed one Sensorwho can implement this, because the alternatives would have been very cumbersome. We wanted a sensor that we could use in the agitator integrate and be able to use them for as many variants of the agitator series as possible ”, Ms. Hauffe specifies the requirement.

Magnetic coupling ensures the integrity of the container and product

permanent magnets in the drive unit form a magnetic coupling with magnets in the mixing head. This is so resilient that above it the mixing head through the container plate with up to 490 min-1 can be driven. To assemble the agitator, the container plate must first be welded into the floor.

thanks to the magnetic Clutch of the drive and mixing head, the integrity of the container is guaranteed throughout the mixing process. Sterility problems and possible contamination, as they can occur with conventional stirrers with shaft feedthrough, are thus excluded. Only the mixing head and the come into contact with the medium ceramic Storage. They are designed and made in such a way that they can be easily cleaned without leaving any residue.

35% shorter interface technology for flat switch boxes in mobile machines

35% shorter interface technology for flat switch boxes in mobile machines

Looking for a magnetic sensor that does that magnetic field can grasp through the container wall, an off-the-shelf solution quickly failed. "We asked a number of providers, but there was nothing useful on the market for the magnetic field to penetrate," reports Anja Hauffe. So an individual solution had to be developed. AWH turned to the sensor and automation specialist Turck, with whom the company had already had good experiences.

Looking for a magnetic sensor that does that magnetic field can grasp through the container wall, an off-the-shelf solution quickly failed. "We asked a number of providers, but there was nothing useful on the market for the magnetic field to penetrate," reports Anja Hauffe. So an individual solution had to be developed. AWH turned to the sensor and automation specialist Turck, with whom the company had already had good experiences.

Hall sensor detects speed and direction of rotation

Turck developed one for the application magnetic field sensor with remote evaluation unit. The actual Hall effect sensor head can therefore be made very compact in order to integrate it on the upper edge of the mixing head holder. In the Hall sensor head there are two active surfaces, so-called Hall probes, which detect the course of the magnetic field by means of an internal time signal offset.

Pressure sensor innovations for digitization in measurement technology

Pressure sensor innovations for digitization in measurement technology

Not only that number of revolutions in itself, but also the direction of rotation are recorded. The Hall sensor is parameterized to a target direction of rotation. If he later recognizes an inverted direction of rotation, there is a malfunction. The LED on the evaluation unit then lights up red and the control also issues a warning message, depending on the user's setting.

Process reliability through monitoring of speed and direction of rotation

Not all customers require additional information such as the recording of the speed and direction of rotation. In special industries like the Pharma industry, Biotechnology but also in potentially explosive systems however, it is precisely the detection of these two variables that can increase the safety of the production process. The pharmaceutical and biotech industries in particular are strongly encouraged to set up, secure and document every process step without errors.

Not all customers require additional information such as the recording of the speed and direction of rotation. In special industries like the Pharma industry, Biotechnology but also in potentially explosive systems however, it is precisely the detection of these two variables that can increase the safety of the production process. The pharmaceutical and biotech industries in particular are strongly encouraged to set up, secure and document every process step without errors.

An incorrect speed can quickly lead to a reduced product yield and high financial losses. An undetected incorrect direction of rotation of the mixing head endangers this Magnetic stirrer itself and could even lead to explosions in potentially explosive areas due to electrostatic charging due to friction.

Construction excludes incorrect installation

When designing the Hall sensors, Turck has gained experience with robust IP67-Products and the necessary know-how for potting electronics. An injection molding tool was created in which the sensor head housing is made from a special Plastic is manufactured. This small plastic part will later be used with the Electronics completely potted.

The Magnetic field sensors must be permanently and precisely at a specific angle to the magnetic fields. This is ensured by the encapsulation and the special design of the Hall sensor unit, which can only be correctly inserted into the groove of the mixing head holder. This construction prevents the Hall effect sensor from slipping. With other manufacturers, the position of the sensors is not fixed and can shift in the event of vibrations, which then leads to a wrong signal and a malfunction.

Visible optical displays make diagnosis easier

The remote evaluation unit is made of robust Stainless Steel manufactured and thus protected against aggressive cleaning media. It has diagnostic LEDs that clearly show the status of the sensors. For example, if the direction of rotation is incorrect, the operator will see it LED glow red. The sensor head, connection cable and evaluation unit can be operated continuously at ambient temperatures of -20 ° to +70 ° C. The sensor and cable can also withstand sterilization (150 ° C) for up to 1 hour. Use in potentially explosive areas with Atex zone 2 is possible.

The remote evaluation unit is made of robust Stainless Steel manufactured and thus protected against aggressive cleaning media. It has diagnostic LEDs that clearly show the status of the sensors. For example, if the direction of rotation is incorrect, the operator will see it LED glow red. The sensor head, connection cable and evaluation unit can be operated continuously at ambient temperatures of -20 ° to +70 ° C. The sensor and cable can also withstand sterilization (150 ° C) for up to 1 hour. Use in potentially explosive areas with Atex zone 2 is possible.

A Hall effect sensor for all magnetic agitators

AWH produces Vpuremix magnetic stirrers in nine different sizes, which are equipped with different numbers of magnets on the drive and mixing head. If the customer orders a mixer, AWH parameterizes the sensor via IO-Link. The IO-Link interface remains closed for the end customer.

"That we all sizes with just one sensor being able to cover is really handy. The software for setting the sensors is also very simple. I select the present agitator size via a dropdown. All other parameters are automatically applied via stored data records. It's done with two to three clicks, ”says the responsible product manager with conviction.

"Also the Assembly of the Hall sensor I find it good. The detached sensor unit cannot be damaged and, unlike other manufacturers, the evaluation unit is not made of plastic, but of stainless steel, ”says Anja Hauffe.

“Customers who ordered a Vpuremix magnetic stirrer for the first time were on the quality and function convinced. Many of them are system builders and have preferred our magnetic stirrers ever since. They also recommend our stirrers to their customers from the pharmaceutical, biotech and food industries, ”says Ms. Hauffe happily.

FAQ

What is a hall sensor?

An Hall Sensor, Hall probe or Hall encoder is a measuring device for measuring magnetic fields. They use the Hall effect discovered by the physicist Edwin Hall. This is based on the fact that the output voltage of the converter depends on the strength and direction of a magnetic field. The voltage triggered by the Lorenz force, also called Hall voltage, is created in a conductor through which a current flows and is located in a magnetic field. Hall sensors detect linear and rotary movements.

You might also be interested in...

IO module secures Resato hydrogen filling stations

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

LED signal light with and without IO-Link

Turck | Your global automation partner

Fieldbus and network technology - communication IO!

Wolfram Stahl is a sales specialist at Turck in Mülheim an der Ruhr.