CAQ Software | Intelligent measurement and testing technology

- Details

- Hits: 5919

CAQ supports and improves computer-aided quality assurance in production in a wide range of industries. The quality management processes are with CAQ software and CAQ systems designed and optimized with and without a cloud connection in the form of a CAQ solution - with the aim of sustainably producing high-quality products in efficient business processes. The article introduces you to some CAQ systems.

Contents

- Universally applicable, intelligent CAQ system

- Parameterization software for IO-Link sensors for the Moneo platform

- QA software with inline-capable evaluation of point clouds

- CAQ and MES: securely networked in the cloud or company network

- Stress-free component measurement with virtual clamping

Universally applicable, intelligent CAQ system

April 27.04.2023, XNUMX | Those responsible for quality management, quality assurance or quality planning will use the universally applicable system measurement and testing software from RTE acoustics treasure. The intelligent CAQ system "SonicTC" helps in automation with the digitalization of quality processes in the production process.

April 27.04.2023, XNUMX | Those responsible for quality management, quality assurance or quality planning will use the universally applicable system measurement and testing software from RTE acoustics treasure. The intelligent CAQ system "SonicTC" helps in automation with the digitalization of quality processes in the production process.

Parameterization software for IO-Link sensors for the Moneo platform

Sep 14.09.2020, XNUMX | Sensors that generate large amounts of data can be connected via digital interfaces Industry 4.0 record and provide the required information. However, systems are also required which convert data into information. IFM Electronic now presents the first module of the digitization platform Moneo to create open and scalable solutions.

Sep 14.09.2020, XNUMX | Sensors that generate large amounts of data can be connected via digital interfaces Industry 4.0 record and provide the required information. However, systems are also required which convert data into information. IFM Electronic now presents the first module of the digitization platform Moneo to create open and scalable solutions.

QA software with inline-capable evaluation of point clouds

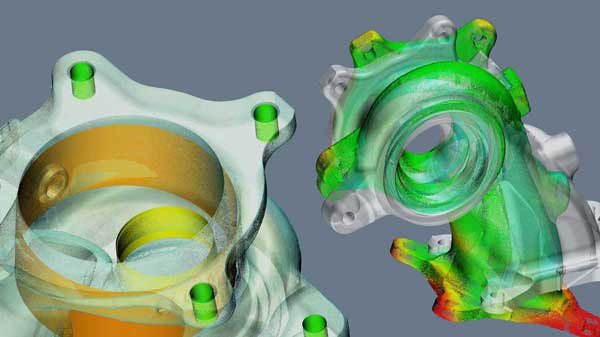

April 16.04.2020, 3 | With Optoinspect XNUMXD Inline from scapos Large amounts of 3D data can be compared quickly and automatically with optimal geometries. This means that each individual component is checked inline and can take place within the production process. You get the maximum parallelization and reuse of calculated results. Especially in the new version 2.7, these lead to quick processing of the point clouds and thus enable real-time data evaluation.

April 16.04.2020, 3 | With Optoinspect XNUMXD Inline from scapos Large amounts of 3D data can be compared quickly and automatically with optimal geometries. This means that each individual component is checked inline and can take place within the production process. You get the maximum parallelization and reuse of calculated results. Especially in the new version 2.7, these lead to quick processing of the point clouds and thus enable real-time data evaluation.

OptoInspect 3D Inline is independent of the used one Digitizer like fringe projection, Light cut, laser scanning can be used. The individual methods of the C++ software library can be flexibly combined via a C interface and adapted to the respective application. The Physikalisch-Technische Bundesanstalt (PTB) certifies that OptoInspect3D Inline has deviations in the smallest class after a comparison with reference values.

The software for computer-aided quality assurance offers robust and efficient methods for checking shape and position tolerances according to DIN EN ISO 1101. The new version includes improvements in the registration of flat objects. A target/actual comparison and the approximation of standard geometries in 2D and 3D are possible, as well as filtering, elimination of outliers, smoothing and thinning out. There is now a new function for curvature-dependent point density reduction.

CAQ and MES: securely networked in the cloud or company network

March 29.03.2020, XNUMX | The central CAQ and MES platform from Böhme & Weihs The new Q Release 15 offers complete and secure networking. The CAQ works locally in the company network or globally in the cloud. This means that CASQ-it is available globally via the web browser. Whether the networking takes place via your own company network, the cloud or a hybrid solution can also be set individually later.

The multi-level security system has 100 percent SSL / TLS encryption. Together with multifactor authentication, it protects all data from unauthorized access. The quality manager determines who can access what.

CAQ and MES from a single source

The interaction of CASQ-it and WEB.MES is enough Networking to the level in Shop floor. This is how WEB.MES controls sampling for quality data collection. Quality and machine metrics flow together to form comprehensive analyses. CASQ-it and WEB.MES thus provide the basis for increasing performance in the areas of manufacturing, processes and product quality.

Edge computing software efficiently increases productivity

Edge computing software efficiently increases productivity

Q-Release 15 also supports companies with innovations and functional enhancements in the implementation of current standards and guidelines. These include audits according to ISO 19011, integration of the layered process audit, implementation of the VDA volume 8D process and support for the Aiag and VDA FMEA manuals.

Technical flexibility and the intelligent security system form a symbiosis and set a new standard for the CAQ / MES systems. This gives companies the security of making the right decisions for the future today.

Stress-free component measurement with virtual clamping

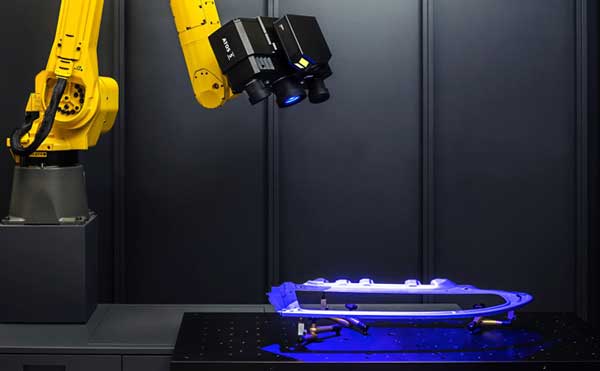

March 23.03.2020, XNUMX | Common shaping processes such as sheet metal forming and injection molding result in deviations from the target specification when measuring components. Such Plastic- Measuring sheet metal components is often complex and involves great effort and high costs. In order to compensate for these deviations when measuring and to simulate the installation situation, components have previously had to be clamped in complex measuring devices. GOM this measurement process can now be carried out using the newly developed technology Virtual clamping greatly simplify.

March 23.03.2020, XNUMX | Common shaping processes such as sheet metal forming and injection molding result in deviations from the target specification when measuring components. Such Plastic- Measuring sheet metal components is often complex and involves great effort and high costs. In order to compensate for these deviations when measuring and to simulate the installation situation, components have previously had to be clamped in complex measuring devices. GOM this measurement process can now be carried out using the newly developed technology Virtual clamping greatly simplify.

The design and manufacture of Clamping devices is not only expensive so far, but also very specific and therefore not flexible in use. Even when the components are used manually by the operator Inaccuraciesthat show up in the measurement data. The measurement data at the clamping points are also missing.

Virtual clamping will make clamping unnecessary in the future

With a new module Virtual clamping With the GOM software it is possible to calculate the clamped state of the real component in the unclamped state. The result of the component measurement is measurement data that can be compared exactly with the clamped component. Statements about the actual delay or jump can also be made without connecting another measurement process. The virtual clamping process is based on the measurement data and using an FEM-based calculation method.

Telecentric Lens | new developments

Telecentric Lens | new developments

It can even be not inherently rigid components measured independently of the real installation position. A new universal bracket in combination with a weight is used for this purpose. The virtual clamping technology is also suitable for measurements with the industrial computer tomograph GOM CT. Since no clamping device can be integrated into this measuring system, small components with optically difficult-to-access geometries can be measured and inspected quickly and precisely with the new technology.

FAQ

What is an MES system?

MES stands for Manufacturing Execution System. This describes the process-related level of a management system in production that is multi-layered. In German, an MES is a production control system.

You might also be interested in...

Universally applicable intelligent CAQ system

Measuring machine | For automated quality control

Gateways | The bridge to the Industry 4.0 factory

Level sensor | Level switch for simple to IIoT use

IFM Electronic | Technology for everyone

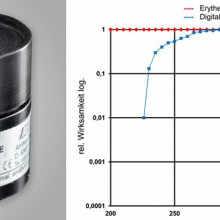

Measure solar radiation and determine UV Eruthem radiation

Jens Struck is a business owner, journalist and web designer at German Online Publisher GbR in Ried.