for mechanical and plant engineering

High-precision cutting tools and non-cutting tools for machines as well as clamping technology for jig and mold construction

Image: Dormer Pramet

for mechanical and plant engineering

High-precision cutting tools and non-cutting tools for machines as well as clamping technology for jig and mold construction

Image: Dormer Pramet

Here you will find new products from the Tooling for construction and production with tools for machine and plant construction for the production of industrial goods, especially for machine tools as well clamping means or entire manual workstations for modern production with the highest precision. The precision tools presented here can be found in the Metalworking for the Automotive industry, electrical industry, Aircraft construction and much more. Commitment.

The precision tool industry is one of the largest specialist areas in mechanical engineering. You manufacture quality products with high-precision cutting tools and non-cutting tools. grips, Workholding as assemblies for the jig and Mold making and entire devices are required by the equipment designer for efficient toolmaking.

Find out about precision tools, fixtures and clamping technology for your Engineering Construction.

Nils Knepper, Product Manager modular PLC / software, Mitsubishi Electric Europe BV, Ratingen, is presenting a manual workstation that can be used to implement zero-error assembly based on the manufacturer's products.

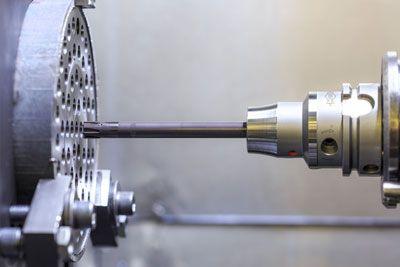

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

There are different chuck for processing workpieces on a machine, including power chucks, jaw chucks or eccentric chucks. They all have in common that they either die Tools such as drills or milling cutters. Or they clamp the ones to be machined as a so-called lathe chuck workpieces on the machine. We present new developments like that here lathe chuck with optimized power transmission, which Röhm will present at the AMB 2022.

Precise machining and extremely tight tolerances are particularly important in medical technology, for example in the manufacture of bone screws or other small medical parts and microcomponents. The fast and reliable production of threads is a particular challenge here. For this reason, Sandvik Coromant has now developed inserts and holders for the "Coromill 325" for use on Swiss-type lathes, which can significantly optimize production processes.

Precise machining and extremely tight tolerances are particularly important in medical technology, for example in the manufacture of bone screws or other small medical parts and microcomponents. The fast and reliable production of threads is a particular challenge here. For this reason, Sandvik Coromant has now developed inserts and holders for the "Coromill 325" for use on Swiss-type lathes, which can significantly optimize production processes.

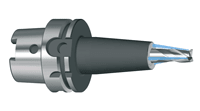

Elco offers a wide range of high-performance tools for mold making and light machining. The company develops tools and solutions for processing panels and profiles made of plastics and composites especially for applications in the aerospace industry and in lightweight construction. It also produces a variety of shrink fit chucks.

Elco offers a wide range of high-performance tools for mold making and light machining. The company develops tools and solutions for processing panels and profiles made of plastics and composites especially for applications in the aerospace industry and in lightweight construction. It also produces a variety of shrink fit chucks.

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.

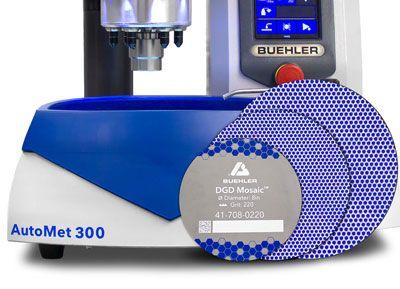

Buehler ITW Test + Measurement introduces its new "Diamond Mosaic" Diamond Grinding Discs (DGD). This fifth series of the DGD family is designed for particularly high material removal rates during sample preparation and is especially suitable for laboratories that work with high-strength or particularly resistant materials.

Buehler ITW Test + Measurement introduces its new "Diamond Mosaic" Diamond Grinding Discs (DGD). This fifth series of the DGD family is designed for particularly high material removal rates during sample preparation and is especially suitable for laboratories that work with high-strength or particularly resistant materials.

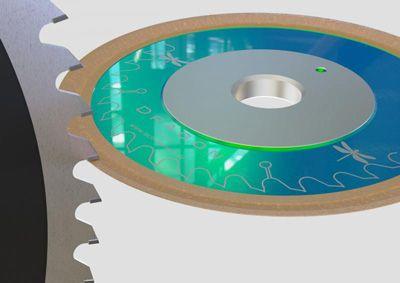

Lach Diamant has succeeded in developing a highly innovative grinding wheel for the face grinding of circular saw blades. This makes regrinding and production grinding more cost-efficient with the highest precision. The unique carrier system with 3-dimensional geometry and extended grinding layer makes grinding even the tightest tooth spaces child's play.

Lach Diamant has succeeded in developing a highly innovative grinding wheel for the face grinding of circular saw blades. This makes regrinding and production grinding more cost-efficient with the highest precision. The unique carrier system with 3-dimensional geometry and extended grinding layer makes grinding even the tightest tooth spaces child's play.

With two newly developed tapping-Tools expanded Rhymes Noris his product portfolio for Aluminum wrought alloys and Cast aluminum alloys, Both tool types, like all thread formers of the "NEO" series, are made from HSSE-PM substrate. However, they differ in properties such as geometry and coating in order to achieve outstanding results in the respective area of application.

With two newly developed tapping-Tools expanded Rhymes Noris his product portfolio for Aluminum wrought alloys and Cast aluminum alloys, Both tool types, like all thread formers of the "NEO" series, are made from HSSE-PM substrate. However, they differ in properties such as geometry and coating in order to achieve outstanding results in the respective area of application.

The “Centrotex” quick-change system from Hainbuch Maßstätze has a new addition to the family: The tried-and-tested interface is now also available in a version for smaller spindles. According to the manufacturer, "Centrotex S" is currently the smallest system available on the market for setting up clamping devices in a matter of seconds. With its diameter of only 224 mm, it is suitable for machines with a small working space.

The “Centrotex” quick-change system from Hainbuch Maßstätze has a new addition to the family: The tried-and-tested interface is now also available in a version for smaller spindles. According to the manufacturer, "Centrotex S" is currently the smallest system available on the market for setting up clamping devices in a matter of seconds. With its diameter of only 224 mm, it is suitable for machines with a small working space.

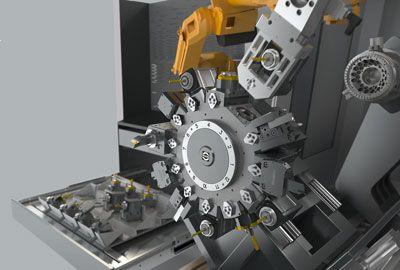

With the fully automatic "Robofix" interface, Sauter is making it possible for the first time to set up tool turrets with driven and static tools with little manpower. With this system, the patented direct drive in the tool turret takes over the central tasks Tool change – the loosening of tools that are no longer required and the clamping of new ones.

With the fully automatic "Robofix" interface, Sauter is making it possible for the first time to set up tool turrets with driven and static tools with little manpower. With this system, the patented direct drive in the tool turret takes over the central tasks Tool change – the loosening of tools that are no longer required and the clamping of new ones.

With the established process Fillet edges can be loud Father the service life of one Carbidewerkzeug extend and improve the PVD layer adhesion. With the rounding and smoothing of the cutting edge the danger of Micro outbreaks reduced. In addition, the cutting edge is mechanically much more stable. These clear machining goals are made possible by the individual process and not by automation.