flexibly and quickly fix workpieces With eccentric clamping modules

- Details

- Hits: 12567

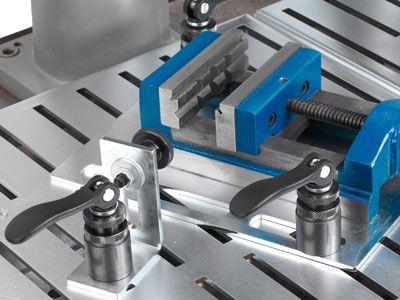

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.

Installation, milling or drilling often have to be done quickly. So it's good if the workpieces can be easily fixed - and even better if you don't even need a tool. Ruwi has designed innovative clamping modules that make exactly that possible. The eccentric clamping modules are produced by the Heinrich Kipp factory, where they are now part of the standard range.

All products and solutions of the Swabian engineering company are based on a clear guiding principle: "We want to keep things as simple as possible," explains Reiner Ruggaber, Managing Director of Ruwi GmbH. "We design and produce solutions that save our customers time and give them a competitive edge." Ruwi is best known for its versatile underfloor milling machines, which come in three different sizes and are now being exported all over the world. According to the company philosophy, the milling machines enable fast set-up times and particularly easy handling. However, the greatest possible time savings are also guaranteed by the products from two recently introduced product ranges: modular organization systems and clamping systems.

All products and solutions of the Swabian engineering company are based on a clear guiding principle: "We want to keep things as simple as possible," explains Reiner Ruggaber, Managing Director of Ruwi GmbH. "We design and produce solutions that save our customers time and give them a competitive edge." Ruwi is best known for its versatile underfloor milling machines, which come in three different sizes and are now being exported all over the world. According to the company philosophy, the milling machines enable fast set-up times and particularly easy handling. However, the greatest possible time savings are also guaranteed by the products from two recently introduced product ranges: modular organization systems and clamping systems.

Efficient workplace design

Ruwi offers both a clamping plate and a complete worktable in the latter area. The 450 x 400 mm clamping plate is made of galvanized sheet steel with a thickness of 4 mm and has an integrated groove pattern. It is designed for mounting on existing machine tables and thus provides real added value. "With the clamping plate, for example, column drilling machines can be upgraded with a manageable investment. The operator can place a vise or stop ruler on the plate and fix it easily, "says Ruggaber.

Ruwi offers both a clamping plate and a complete worktable in the latter area. The 450 x 400 mm clamping plate is made of galvanized sheet steel with a thickness of 4 mm and has an integrated groove pattern. It is designed for mounting on existing machine tables and thus provides real added value. "With the clamping plate, for example, column drilling machines can be upgraded with a manageable investment. The operator can place a vise or stop ruler on the plate and fix it easily, "says Ruggaber.

The worktable is a further development of the plate and offers a variety of application possibilities for production, assembly and measuring technology based on the modular principle. Workpieces, individual parts or subassemblies can be freely positioned and fixed thanks to grooves and perforated grids. The dimensions of the table are modularly dimensioned with 1000 x 500 mm. In addition, individual clamping tables can be easily connected with each other - this quickly expands the range of action for larger components. Additional support surfaces also offer table extensions, which are hung on the lateral mounting rails and clamped.

Greatest possible time savings

For both clamping systems table and clamping plate, there is an extensive range of accessories, with which workpieces can be easily fixed and clamped. The highlight is a tool-free operated eccentric clamping module. It consists of a sprung bolt, which is pressed into the groove and fixed by an eccentric lever. "This makes it possible to clamp components very easily and flexibly without the need for a tool," explains Ruggaber. "Insofar the modules complement our time-saving clamping systems optimally."

For both clamping systems table and clamping plate, there is an extensive range of accessories, with which workpieces can be easily fixed and clamped. The highlight is a tool-free operated eccentric clamping module. It consists of a sprung bolt, which is pressed into the groove and fixed by an eccentric lever. "This makes it possible to clamp components very easily and flexibly without the need for a tool," explains Ruggaber. "Insofar the modules complement our time-saving clamping systems optimally."

The idea for these clamping modules comes from Ruwi. Ruggaber turned to the Heinrich Kipp factory, which continues to set standards with its developments in the field of clamping technology, standard elements and control panels. The two companies have been working together for years: "We have been using Kipp solutions since the company was founded," confirms Ruggaber. "We ourselves set the highest quality standards for our products, and the operating and accessory parts must also meet these standards. With Kipp we have found a suitable partner. Last but not least, the spatial proximity to Kipp played a role ", says the managing director:" Our suppliers are all in the immediate vicinity, which means short distances in the vote. "

A product for two companies

After a joint coordination and development phase, Kipp finally produced the samples of the eccentric clamping modules and was finally so convinced of the new product that they decided to include the solution in their own standard program. "The product concept of Ruwi is simple but unique in the market and therefore has great potential," emphasizes Gerd Wiedemaier, technical customer consultant at the Heinrich Kipp plant. "At Kipp we have the infrastructure to produce the modules in large numbers. Thus, the eccentric clamping modules are a good example of an exemplary cooperation between two partners, resulting in a win-win situation for both sides. "

After a joint coordination and development phase, Kipp finally produced the samples of the eccentric clamping modules and was finally so convinced of the new product that they decided to include the solution in their own standard program. "The product concept of Ruwi is simple but unique in the market and therefore has great potential," emphasizes Gerd Wiedemaier, technical customer consultant at the Heinrich Kipp plant. "At Kipp we have the infrastructure to produce the modules in large numbers. Thus, the eccentric clamping modules are a good example of an exemplary cooperation between two partners, resulting in a win-win situation for both sides. "

At Ruwi, the eccentric clamping modules are now available as part of the clamping systems, but at Kipp as a single product and in larger quantities. "For us, the new solutions are a good addition to the product range," explains Gerd Wiedemaier. In the field of clamping elements, Kipp already has around 50 product families on offer, including clamps, eccentric levers and clamps, clamping hooks as well as pull-down and wedge clamps. The Heinrich Kipp factory produces in Germany with a large machine park. All products undergo rigorous quality assurance here.

Press, turn, fix - done

The eccentric clamping modules can be used on common aluminum profile systems or on T-slot tables for attaching, clamping or clamping components and workpieces. Because the lever and the hammer nut are aligned, the module can be easily inserted from above into the T-slot. It is then securely tightened via the eccentric lever, the component jams tight. By screwing in or unscrewing the adjusting nut, the operator can adapt the clamping stroke flexibly to the height of the component and the groove depth. The solutions are designed for 8 mm profile grooves, but can also be used for 10 or 12 mm grooves by adjusting the eyelets. Kipp offers the modules in four different designs and two sizes with a clamping force of 2,5 or 4 kN.

The eccentric clamping modules can be used on common aluminum profile systems or on T-slot tables for attaching, clamping or clamping components and workpieces. Because the lever and the hammer nut are aligned, the module can be easily inserted from above into the T-slot. It is then securely tightened via the eccentric lever, the component jams tight. By screwing in or unscrewing the adjusting nut, the operator can adapt the clamping stroke flexibly to the height of the component and the groove depth. The solutions are designed for 8 mm profile grooves, but can also be used for 10 or 12 mm grooves by adjusting the eyelets. Kipp offers the modules in four different designs and two sizes with a clamping force of 2,5 or 4 kN.

The special feature of the eccentric clamping modules lies in their flexibility and the simple and fast operation without any tools; an adjustment or movement of the workpieces is possible at any time and quickly implemented. "There are also many possible scenarios beyond toolmaking in terms of possible applications," says Ruggaber. "It would also be possible, for example, to install frequently used inspection doors or protective devices with it. At trade fairs, we find that prospects immediately have new ideas for use as soon as they see the product for the first time. "There is no limit to the creativity of the clamping modules - and thanks to the long service life, a module has countless applications. "The eccentric clamping modules can always be dismantled and reused," confirms Gerd Wiedemaier. "Like everything that Kipp produces, they fulfill the highest quality standards and are characterized by a very long shelf life.

You might also be interested in...

This snap lock locks securely

Ergonomic controls and standard parts

Indexing bolts / locking bolts from Kipp

Heinrich Kipp work | Inventor of the spaetzle machine

Clamping lever with safety function or solid plastic handle