Diamond grinding wheels for high material removal saves time in quality control

- Details

- Hits: 4420

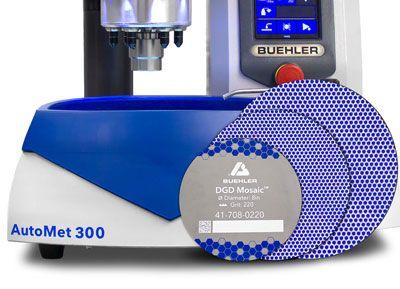

Buehler ITW Test + Measurement introduces its new "Diamond Mosaic" Diamond Grinding Discs (DGD). This fifth series of the DGD family is designed for particularly high material removal rates during sample preparation and is especially suitable for laboratories that work with high-strength or particularly resistant materials.

Buehler ITW Test + Measurement introduces its new "Diamond Mosaic" Diamond Grinding Discs (DGD). This fifth series of the DGD family is designed for particularly high material removal rates during sample preparation and is especially suitable for laboratories that work with high-strength or particularly resistant materials.

The diamond wheels are magnetic backed and available in 8 ", 10" and 12 "pulley diameters as well as 120, 220, 320, 400 and 1000 grain sizes. Typical applications include effective grinding of steel, sintered hard metals, thermal spray coatings and other hard materials.

Best results are achieved with the manufacturer's high-performance grinding and polishing equipment designed for demanding applications in near-production quality control. There, the new diamond grinding wheels can significantly reduce the time required for sample preparation in many industries. For example, they are used in the automotive industry for grinding hard and heat-treated steels or other alloys, in aerospace engineering for superalloys and thermal spray coatings, or in tool production for grinding hard metal samples.

The Buder DGD Mosaic diamond grinding wheels are suitable for high-strength material removal as well as for the rapid removal of damage caused by cutting.